Fundamentals

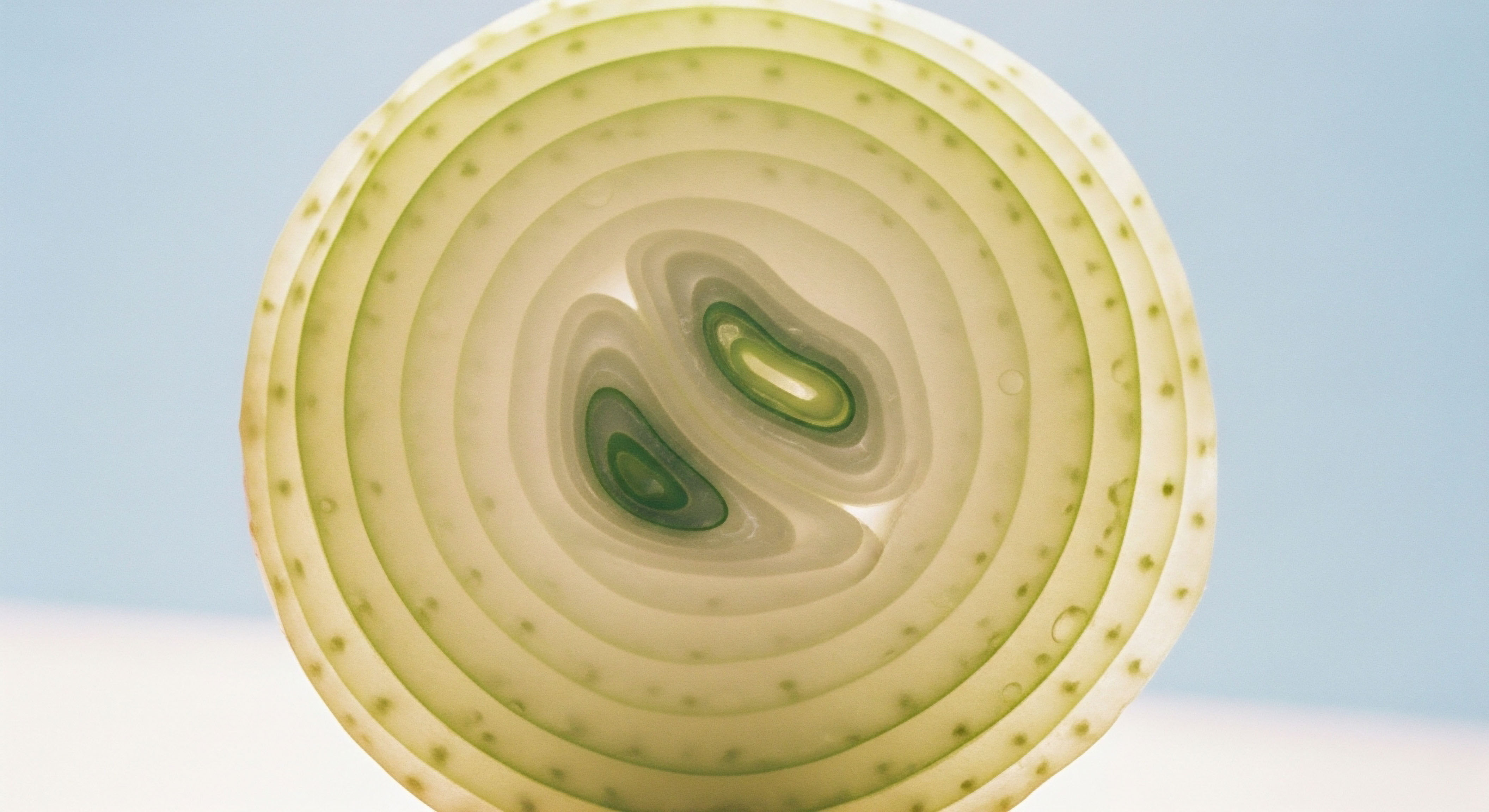

Your journey toward understanding your body’s internal communication system begins with a single, profound recognition ∞ you are a living network of information. The fatigue, the subtle shifts in mood, the metabolic changes you feel ∞ these are signals from within. When we consider therapeutic peptides, we are engaging with this system on its own terms.

These molecules are messengers, keys designed to fit specific locks within your cells. The question of their manufacturing is, at its heart, a question of informational integrity. A precisely crafted key opens the door to renewed function. An imperfect one may not fit, or worse, it could jam the lock entirely.

This is where the concept of manufacturing standards enters the conversation. Think of these standards as the master blueprint for crafting that perfect key, every single time. The global gold standard is known as Good Manufacturing Practice Meaning ∞ Good Manufacturing Practice (GMP) defines a system of regulations for manufacturing processes and facilities. (GMP).

It is a comprehensive system of control and documentation that governs every conceivable aspect of production, from the purity of the raw materials to the sterile conditions of the facility and the calibration of the equipment. Adherence to GMP is the bedrock of trust in any pharmaceutical product, ensuring that the vial in your hand contains a substance of verified identity, purity, potency, and safety. It is the system that translates a chemical formula into a reliable therapeutic tool.

The integrity of a therapeutic peptide is a direct reflection of the standards governing its creation.

Different parts of the world, however, interpret and enforce this blueprint with their own distinct areas of emphasis. The two most prominent regulatory bodies are the United States Food and Drug Administration Meaning ∞ The Food and Drug Administration (FDA) is a U.S. (FDA) and the European Medicines Agency (EMA). Both organizations share the same fundamental goal of protecting public health.

They both demand rigorous adherence to GMP principles. Their approaches, while leading to the same destination of quality assurance, travel along slightly different paths, shaped by their unique legal and philosophical frameworks. Understanding these distinctions is the first step in becoming an informed participant in your own health protocol.

The Universal Language of Quality

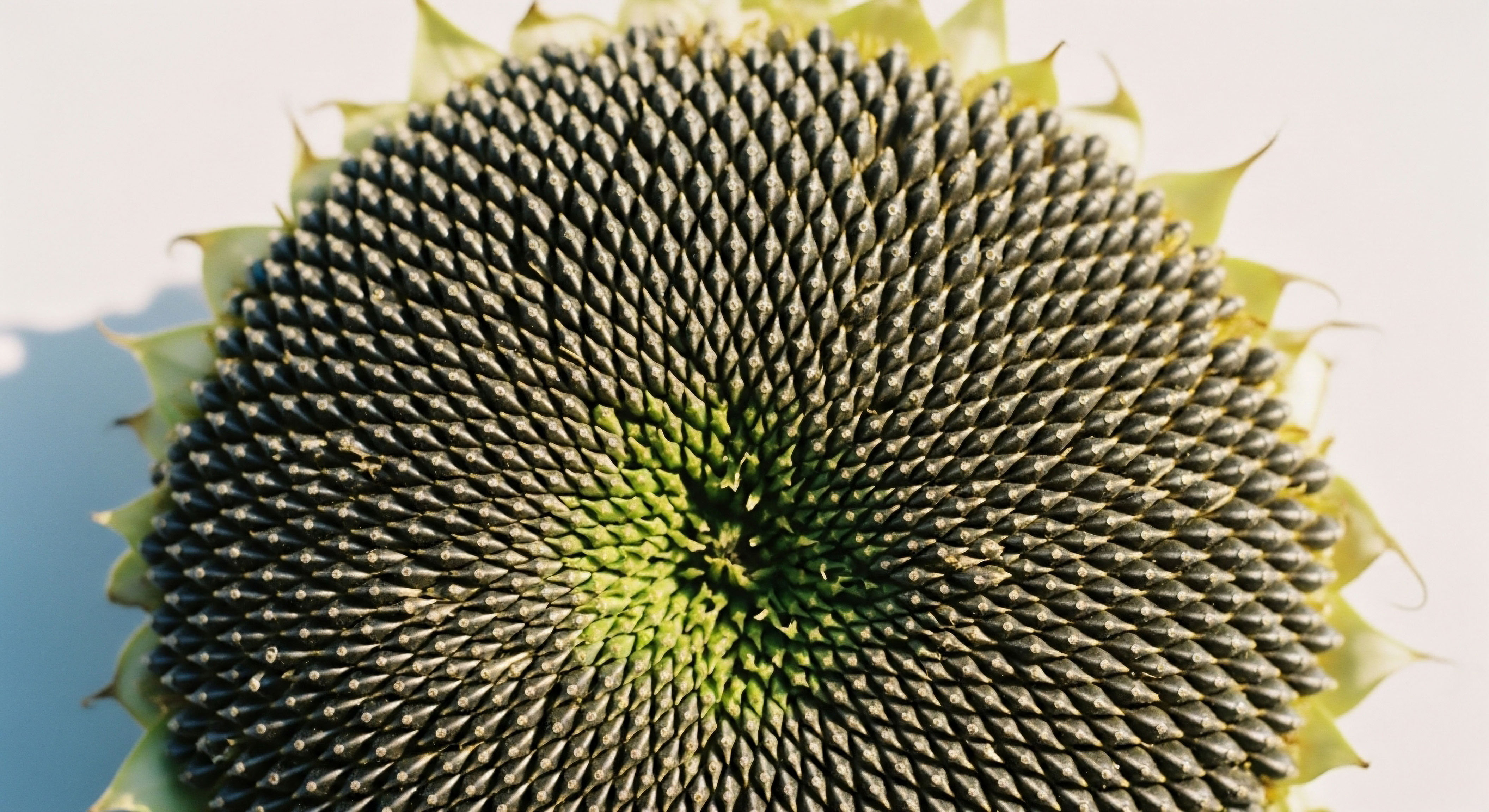

Good Manufacturing Practice provides a universal framework for producing high-quality, safe, and effective pharmaceutical products. This structured system governs every stage of the manufacturing process, ensuring consistency and minimizing risks. The core tenets of GMP are universally accepted and form the basis of all pharmaceutical regulation worldwide.

- Traceability ∞ Every component, from the initial chemical building blocks to the final packaging, must be documented. This creates a complete history for every batch, allowing any issue to be traced to its source for immediate correction.

- Purity ∞ The process must guarantee that the final peptide is free from harmful contaminants. This involves stringent testing at multiple stages to identify and eliminate any unwanted substances.

- Consistency ∞ GMP mandates validated processes to ensure that every batch of a peptide is identical in composition and performance to the one before it. This reliability is essential for predictable therapeutic outcomes.

- Facility and Personnel ∞ The manufacturing environment itself is tightly controlled. Air filtration, temperature regulation, and rigorous sanitation protocols are mandatory to prevent contamination. The personnel involved undergo continuous training in these strict hygiene and operational procedures.

What Are the Core Jurisdictional Philosophies?

While both the FDA and EMA are anchored to GMP, their regulatory postures reveal different priorities. The FDA’s system is often characterized by its rigorous, data-driven enforcement and its clear categorization of products. The agency maintains specific lists and definitions that determine a substance’s legal status, such as whether a peptide can be compounded in a pharmacy or is restricted to research applications. This creates a bright-line system where compliance is meticulously checked against established statutes.

The EMA, representing the European Union, tends to operate with a perspective that emphasizes a holistic view of the product’s lifecycle. Its guidelines often focus on the “quality by design” principle, where risk management and a deep understanding of the manufacturing process are built in from the very beginning.

The EMA places a profound emphasis on characterizing the purity profile of a peptide, viewing it as one of the most vital quality attributes. This approach fosters a continuous dialogue between the manufacturer and the regulator about ensuring the product’s quality and safety throughout its development.

Intermediate

As we move deeper, the abstract concept of “standards” solidifies into a set of concrete, measurable requirements. For the person seeking to optimize their health, the distinction between a peptide sourced from a GMP-compliant facility and one from a “research use only” (RUO) chemical supplier is the most significant variable in their entire protocol.

The differences in manufacturing standards across jurisdictions like the U.S. and E.U. are subtle yet meaningful, but the chasm between a regulated pharmaceutical and an unregulated chemical is immense. This is where an understanding of the regulatory landscape becomes a personal risk management strategy.

The FDA, for instance, draws a hard line between different grades of substances. A peptide intended for human use must be produced as a pharmaceutical-grade Active Pharmaceutical Ingredient Meaning ∞ The Active Pharmaceutical Ingredient, often abbreviated as API, refers to the biologically active component within a drug product responsible for its intended therapeutic effect. (API) in a facility registered with and inspected by the FDA. Products labeled “research use only” exist outside this framework.

They are not subject to the same stringent manufacturing controls, and their use in humans is not sanctioned. This bifurcation has profound implications. A vial of Sermorelin or Ipamorelin from a compounding pharmacy operating under state and federal law is a world apart from a product with the same name purchased from an online RUO vendor. The former is subject to rules regarding purity and sterility; the latter may not be.

A peptide’s source determines its quality, a variable that directly influences both biological efficacy and personal safety.

The EMA and FDA both issue detailed scientific guidelines that manufacturers must follow. These documents specify the types of analytical tests required to prove a peptide’s identity and purity. High-Performance Liquid Chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (HPLC) is a universally mandated technique used to separate the target peptide from any process-related impurities.

Mass Spectrometry is used to confirm the exact molecular weight of the peptide, verifying its primary structure. Where the agencies may diverge is in the specific acceptance criteria for certain impurities or the level of detail required in documenting the rationale for the chosen analytical methods.

A Comparative Look at Regulatory Frameworks

The table below offers a simplified juxtaposition of the regulatory focus of the FDA and EMA concerning therapeutic peptides. Both agencies demand comprehensive data, yet their points of emphasis can differ, reflecting their distinct regulatory philosophies.

| Regulatory Aspect | FDA (U.S. Food and Drug Administration) Focus | EMA (European Medicines Agency) Focus |

|---|---|---|

| Impurity Thresholds | Establishes specific limits for known and unknown impurities. The guidance is highly quantitative, with clear action thresholds. | Emphasizes the identification and qualification of any impurity. The motto is “any impurity must be justified,” focusing on its potential biological impact. |

| Starting Materials | Requires that raw materials be sourced from approved suppliers with extensive documentation and testing to verify identity and purity before use. | Places a strong emphasis on controlling the quality of starting materials as part of a holistic “Quality by Design” approach, often requiring deeper characterization of the supplier’s process. |

| Analytical Methods | Mandates the use of validated analytical methods, with a focus on the robustness and reproducibility of the tests used for batch release. | Requires a detailed justification for the selection of analytical methods, linking the chosen techniques directly to the specific risks associated with the peptide’s structure and synthesis route. |

| Compounding vs. Commercial | Maintains a very clear, legally defined distinction. Peptides for compounding must be on a specific approved list (the 503A Bulks List) or be a component of an FDA-approved drug. | Regulation of compounding (magistral preparations) is primarily handled at the individual member state level, leading to more variation across Europe compared to the centralized U.S. system. |

What Is the Difference between GMP and Research Grade?

Understanding the gap between these two categories is perhaps the most critical piece of knowledge for anyone considering peptide therapy. The distinction is not one of degree, but of kind. One is a therapeutic article, the other is a chemical commodity.

- Pharmaceutical Grade (GMP) ∞ This is a legally defined standard. The peptide is manufactured in a facility that adheres to Good Manufacturing Practice. The process is designed to produce a product of specified purity, content, and biological activity, suitable for human use. Extensive testing confirms the absence of harmful contaminants like endotoxins, heavy metals, and residual solvents. The entire history of the product is documented and auditable by regulatory agencies.

- Compounded Peptides ∞ These are prepared in a pharmacy for a specific patient pursuant to a prescription. While not subject to the same pre-market approval process as commercial drugs, licensed compounding pharmacies are regulated and must adhere to standards like those found in USP for sterile preparations. They are required to source their active ingredients from FDA-registered facilities. Their purpose is to provide access to medications that are not commercially available in a specific dosage form.

- Research Use Only (RUO) ∞ This label signifies that the product is intended for laboratory research, not for human administration. There are no regulatory requirements for GMP manufacturing, sterility testing, or purity verification for RUO products. The percentage of the target peptide can vary wildly, and the presence of synthesis-related impurities is common. Using an RUO product therapeutically introduces a host of unknown variables and potential risks.

Academic

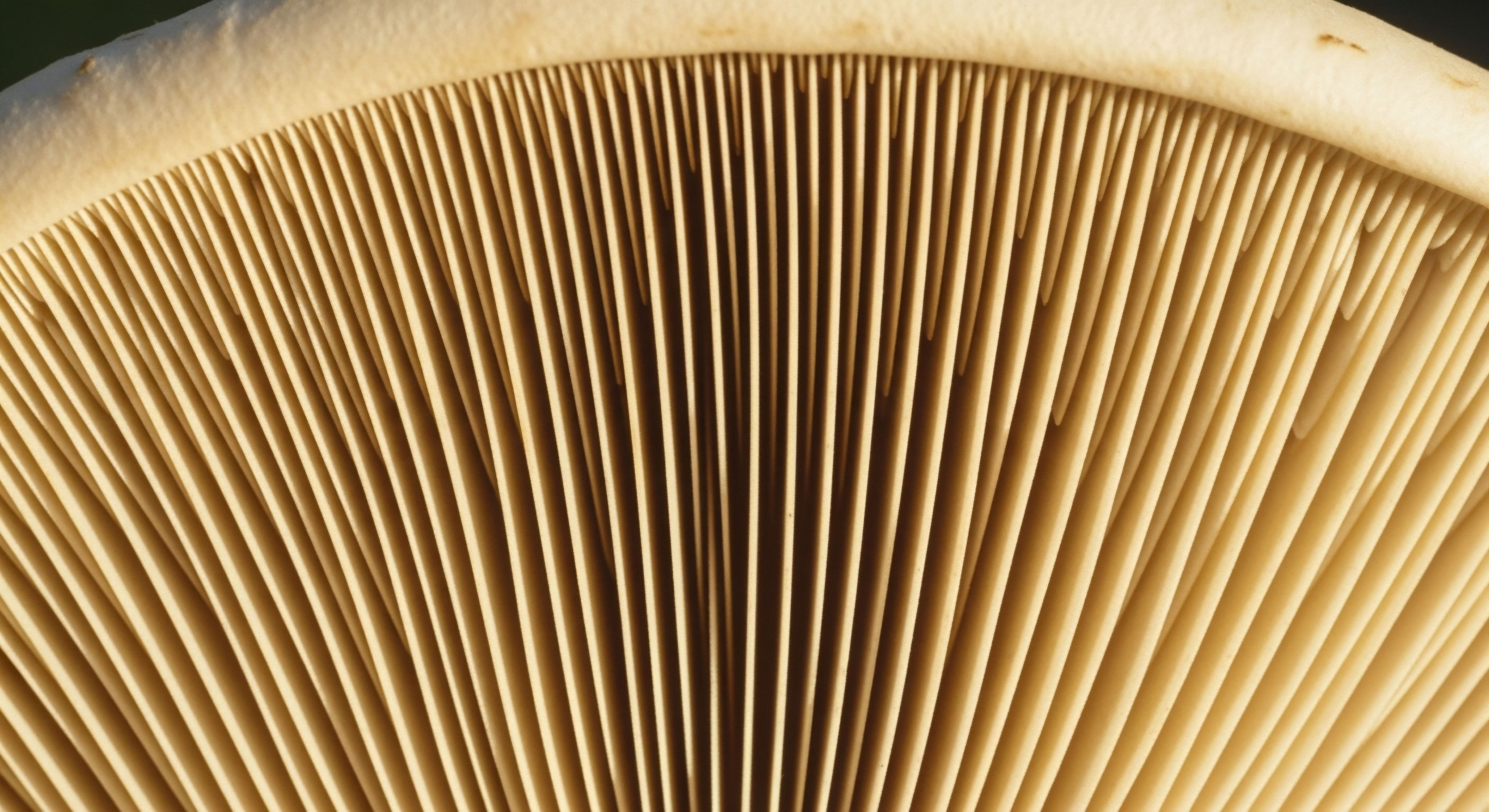

At the most sophisticated level of analysis, the international standards governing peptide manufacturing converge on a single, shared scientific obsession ∞ the rigorous characterization and control of impurities. An impurity is any component present in the final peptide product that is not the intended chemical entity.

From a biological perspective, an impurity represents a structural deviation, a piece of molecular misinformation that can disrupt the intended physiological signal. The central challenge in peptide therapeutics is that even minute impurities, present at levels below 1%, can possess potent, unintended biological activity, including the potential to provoke an immune response.

The guidelines from regulatory bodies like the FDA and EMA are built upon this scientific reality. They mandate a deep analytical investigation into the peptide’s composition, moving far beyond a simple confirmation of the primary sequence. This involves the use of orthogonal analytical techniques, primarily advanced forms of chromatography and mass spectrometry, to create a comprehensive profile of the drug substance.

The goal is to detect, identify, and quantify every significant peptide-related impurity, such as deletion sequences Meaning ∞ Deletion sequences represent the absence of genetic material, DNA or RNA, removed from a chromosome or gene. (where an amino acid is missing), insertion sequences, or products of side reactions like deamidation or oxidation. Each of these represents a distinct molecular species with its own unique, and potentially problematic, pharmacological profile.

The biological consequence of a peptide impurity is a function of its structure, creating a critical link between manufacturing chemistry and clinical immunogenicity.

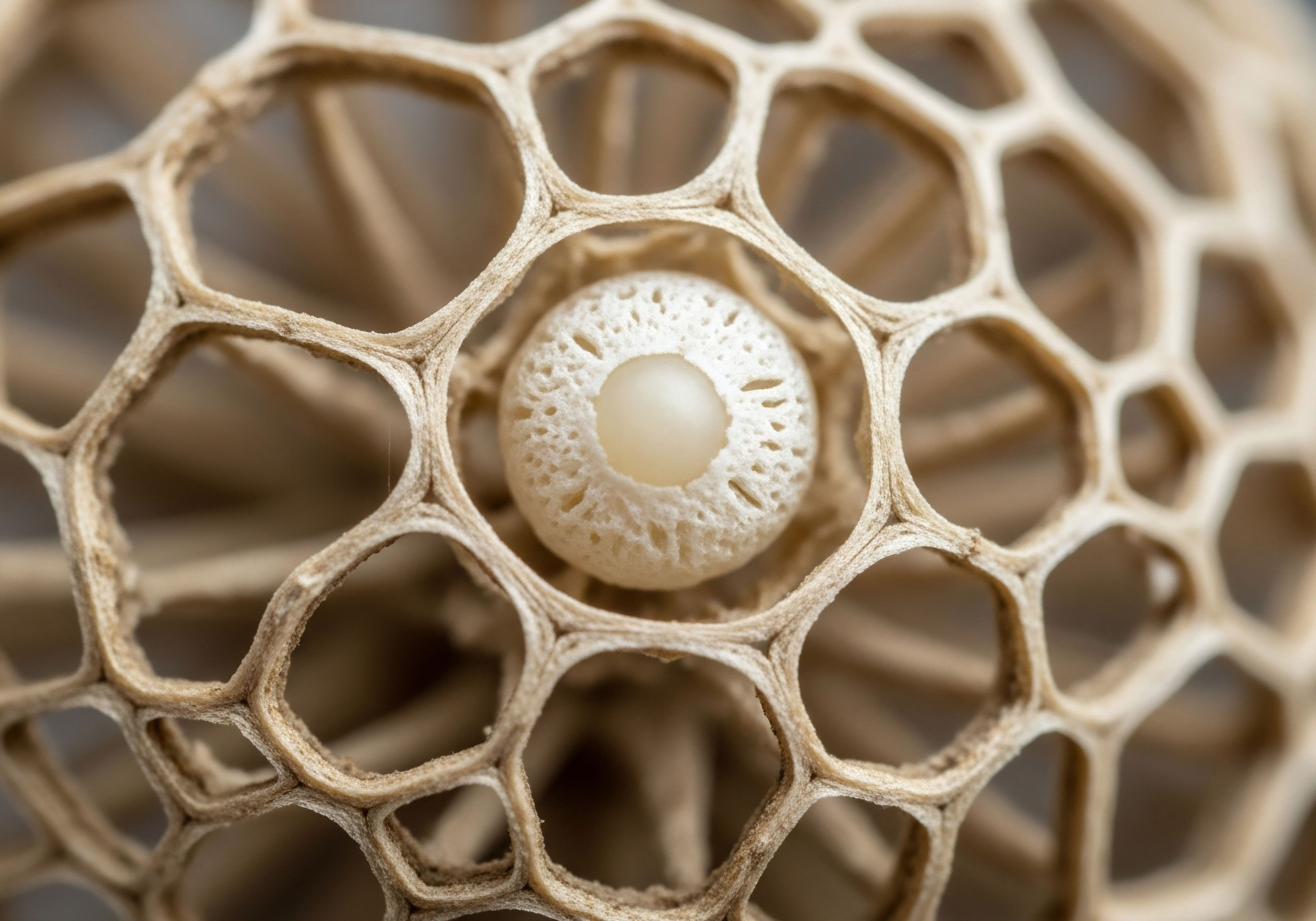

The concept of immunogenicity is paramount. This is the propensity of a therapeutic peptide to trigger an unwanted immune response. The immune system is exquisitely sensitive to molecular structures. A subtle change in a peptide’s three-dimensional shape, or the presence of a co-eluting impurity, can be sufficient for it to be recognized as “foreign.” The FDA guidelines Meaning ∞ The Food and Drug Administration (FDA) guidelines are comprehensive regulations and standards set by the U.S. on immunogenicity risk Meaning ∞ Immunogenicity risk denotes the potential for an administered therapeutic agent, especially biologics or certain hormone preparations, to trigger an undesirable immune response. explicitly state that any new impurity must be assessed for its potential to bind to Major Histocompatibility Complex (MHC) molecules, the cellular machinery that presents antigens to T-cells.

This concern transforms the chemical analysis of impurities from a simple quality control exercise into a predictive immunological risk assessment.

Deep Dive into Impurity Classes and Consequences

The nature of an impurity dictates its potential biological effect. The table below details common classes of process-related impurities found in synthetically manufactured peptides and their documented or theoretical physiological consequences. Understanding these connections illuminates the rationale behind the stringent controls imposed by regulatory agencies.

| Impurity Class | Description | Potential Biological Consequence |

|---|---|---|

| Deletion Sequences | Peptides missing one or more amino acid residues from the intended sequence, often due to incomplete coupling during synthesis. | May act as a competitive antagonist at the target receptor, blocking the action of the correct peptide. Could also possess no activity or an entirely different, off-target activity. |

| Truncated/Extended Sequences | Peptides that are shorter or longer than the target sequence due to premature termination or erroneous addition of amino acids. | Can lead to altered binding affinity and efficacy. In some cases, these fragments may be more immunogenic than the parent molecule. |

| Diastereomeric Impurities | Peptides containing an amino acid that has undergone epimerization, changing its stereochemistry (e.g. L-amino acid to a D-amino acid). | This can drastically alter the peptide’s three-dimensional structure, rendering it inactive. It may also make the peptide resistant to normal enzymatic degradation, prolonging its circulation and increasing the chance of an immune reaction. |

| Oxidation/Deamidation Products | Chemical modifications of susceptible amino acid side chains (e.g. Methionine, Asparagine) during synthesis or storage. | Can reduce or eliminate biological activity. Deamidation, which introduces a new negative charge, is a known trigger for immunogenicity in some protein therapeutics. |

| Residual Solvents/Reagents | Trace amounts of chemicals used during the synthesis and purification process that are not fully removed from the final product. | These are non-biological and can be directly toxic. Regulatory limits for residual solvents are extremely strict and based on extensive toxicological data. |

How Do Regulators Address Immunogenicity Risk?

The FDA and EMA have developed sophisticated frameworks for assessing immunogenicity risk, acknowledging that it is a multifactorial issue. The approach integrates chemistry, manufacturing, and controls (CMC) with non-clinical and clinical data. Any change in the manufacturing process, even one that appears minor, triggers a re-evaluation of the impurity profile and its potential impact on immunogenicity.

For instance, if a manufacturer changes the supplier of a raw material, they must demonstrate that this change does not introduce new impurities that could possess T-cell epitopes. This deep connection between the manufacturing process and the ultimate biological response in the patient is the core principle of modern pharmaceutical regulation. It is a recognition that the process defines the product, and the product’s purity defines its safety.

References

- Currier, Jeffrey R. et al. “Peptide Impurities in Commercial Synthetic Peptides and Their Implications for Vaccine Trial Assessment.” Clinical and Vaccine Immunology, vol. 15, no. 2, 2008, pp. 267-76.

- “Regulatory Guidelines for the Analysis of Therapeutic Peptides and Proteins.” Pharmaceuticals (Basel), vol. 16, no. 11, 2023, p. 1587.

- “Beyond Efficacy ∞ Ensuring Safety in Peptide Therapeutics through Immunogenicity Assessment.” Biomedicines, vol. 12, no. 5, 2024, p. 988.

- BioPharmaSpec. “Process-Related Impurities in Peptides ∞ Key Considerations and Analytical Approaches.” BioPharmaSpec, 2024.

- European Medicines Agency. “Development and manufacture of synthetic peptides – Scientific guideline.” EMA/CHMP/QWP/78243da12/2012, 2012.

- Polypeptide Group. “Quality control in peptide manufacturing ∞ specifications for GMP peptides.” Polypeptide.com, Accessed 2024.

- Frier Levitt. “Regulatory Status of Peptide Compounding in 2025.” Frier Levitt Attorneys at Law, 2024.

- Florida Healthcare Lawfirm. “The FDA Is Expanding Its Oversight ∞ Research Use Only Peptide Businesses Should Be Watching Manufacturing Closely.” Florida Healthcare Lawfirm, 2024.

- Behrendt, R. et al. “Advances in Fmoc solid-phase peptide synthesis.” Journal of Peptide Science, vol. 22, no. 1, 2016, pp. 4-27.

- Bodanszky, M. “Principles of Peptide Synthesis.” Springer-Verlag, 1993.

Reflection

The Architecture of Your Own Renewal

You have now traveled from the surface-level question of jurisdictional differences to the deep, molecular basis of therapeutic integrity. This knowledge does more than satisfy intellectual curiosity. It recalibrates your perspective. The vials, the protocols, the lab results ∞ they cease to be abstract medical artifacts and become what they truly are ∞ tools for engaging with your own biology.

The meticulous standards of GMP, the analytical rigor of impurity profiling, and the immunological foresight of regulatory science are all part of a larger architecture of trust. They are the scaffolding that allows for a confident and intentional approach to personal wellness.

This understanding transforms you from a passive recipient of a protocol into an active, informed partner in your own health journey. It equips you to ask more precise questions, to discern the profound difference between a clinically validated therapeutic and an unregulated substance, and to appreciate that true biological optimization is built upon a foundation of uncompromising quality.

The path forward is a personal one, a unique dialogue between your body’s signals and the targeted information you provide it. The journey begins not with the first injection, but with the moment you recognize that the quality of the information matters most of all.