Fundamentals

Your journey toward hormonal balance often begins with a deep, personal recognition that something within your body’s intricate communication network has shifted. You feel it in your energy, your mood, your sleep, and your overall sense of vitality. This lived experience is the most important data point you possess.

When you seek clinical support, you encounter a world of therapeutic options, and understanding the origin of your medication is a foundational piece of your empowerment. The conversation about your health protocol rightfully starts with you, and it extends to the very source of the molecules designed to restore your system’s equilibrium.

Two primary categories of medications exist to meet your needs ∞ those approved by the U.S. Food and Drug Administration (FDA) and those prepared through a process called compounding.

An FDA-approved medication represents a promise of uniformity and predictability. Every tablet, injection, or patch has been subjected to a rigorous, multi-phase clinical trial process designed to verify its safety, efficacy, and consistency.

The manufacturing standards, known as Current Good Manufacturing Practices (CGMP), govern every step of its creation, from the purity of the raw ingredients to the stability of the final product on the pharmacy shelf. This system is built to produce millions of doses that are, for all intents and purposes, identical.

When your protocol involves a medication like commercially available Testosterone Cypionate, you are receiving a product backed by this extensive framework of standardization. The goal is to ensure that the dose you receive this week is precisely the same as the one you received last week and the one you will receive next week, providing a stable foundation for your therapy.

A medication’s manufacturing process directly influences its consistency, which is a key factor in achieving stable and predictable results in hormonal therapy.

Compounded medications, conversely, are born from the need for personalization. Your unique biochemistry, sensitivities, or therapeutic requirements may mean that a mass-produced product is unsuitable. You might have an allergy to a specific filler in an approved tablet, or your treatment protocol, such as for peptide therapy or a specific dose of progesterone, may require a strength or delivery method that simply does not exist on the commercial market.

In these instances, a physician can prescribe a compounded medication. A licensed pharmacist or physician then combines or alters ingredients to create a formulation tailored specifically for you. This is a return to the roots of pharmacy, where a practitioner creates a specific remedy for an individual patient. This process allows for immense therapeutic flexibility, enabling protocols that are precisely calibrated to your body’s signals and your clinical needs.

What Is the Core Purpose of Each Medication Type?

Understanding the intended role of each medication type provides clarity on why your clinician might choose one path over the other. FDA-approved drugs are designed for broad patient populations with common conditions. Their development is a massive undertaking, aimed at creating a single, reliable tool that physicians can use with a high degree of confidence in its performance.

Think of the standard weekly intramuscular injections of Testosterone Cypionate used in many male hormone optimization protocols; this is a workhorse medication, standardized and widely studied.

Compounded preparations serve a different, more focused purpose. They fill the therapeutic gaps left by mass manufacturing. For a woman requiring a very low dose of testosterone in a topical cream, or an athlete using a specific peptide combination like Ipamorelin and CJC-1295 for tissue repair and recovery, compounding is the only way to obtain these precise formulations.

The purpose here is clinical precision, adapting the therapy to the patient’s unique biological landscape. This pathway is essential for advancing personalized medicine and allows your protocol to be as unique as you are.

| Attribute | FDA-Approved Medications | Compounded Medications |

|---|---|---|

| Primary Goal | To provide a safe, effective, and consistent treatment for a broad population. | To create a personalized medication for an individual patient’s specific needs. |

| Development Focus | Large-scale clinical trials and standardized manufacturing. | A specific prescription from a practitioner for an identified patient. |

| Ideal Use Case | Conditions where a standard dose and delivery form are effective. | Allergies to inactive ingredients, need for unique dosages, or combination therapies. |

| Example in Hormonal Health | Standard Testosterone Cypionate for TRT. | Custom-dosed bioidentical progesterone cream or specific peptide blends. |

Intermediate

As you become more familiar with your own health protocol, your questions naturally become more specific. You move from the “what” to the “how.” How, exactly, do the manufacturing environments differ between the vial of an FDA-approved hormone and your custom-formulated peptide solution?

The answer lies in the specific regulatory frameworks that govern their creation. These frameworks are detailed, technical, and directly impact the quality, consistency, and reliability of the medication you use to support your body’s endocrine system.

FDA-approved drugs are produced in facilities that adhere to a stringent set of rules known as Current Good Manufacturing Practices (CGMP). These regulations are enforced by the FDA and cover every aspect of production. CGMP ensures that the drug meets the highest standards of quality and that its identity, strength, and purity are consistent from batch to batch.

This is a legally enforceable standard. A facility producing an FDA-approved medication undergoes regular and rigorous inspections to ensure ongoing compliance. This oversight is designed to prevent contamination, mix-ups, and deviations in potency, which are critical for any medication and especially for hormones that operate on a sensitive feedback loop system.

A Closer Look at Manufacturing Requirements

The CGMP framework is exhaustive. It dictates the physical conditions of the manufacturing plant, the training and qualifications of the personnel, the validation of every process, and the meticulous documentation of every step. For a substance like Testosterone, this means the raw material is tested for purity upon arrival, the process of synthesizing it into an injectable form is validated to ensure consistency, and the final product is tested for sterility and correct concentration before being released.

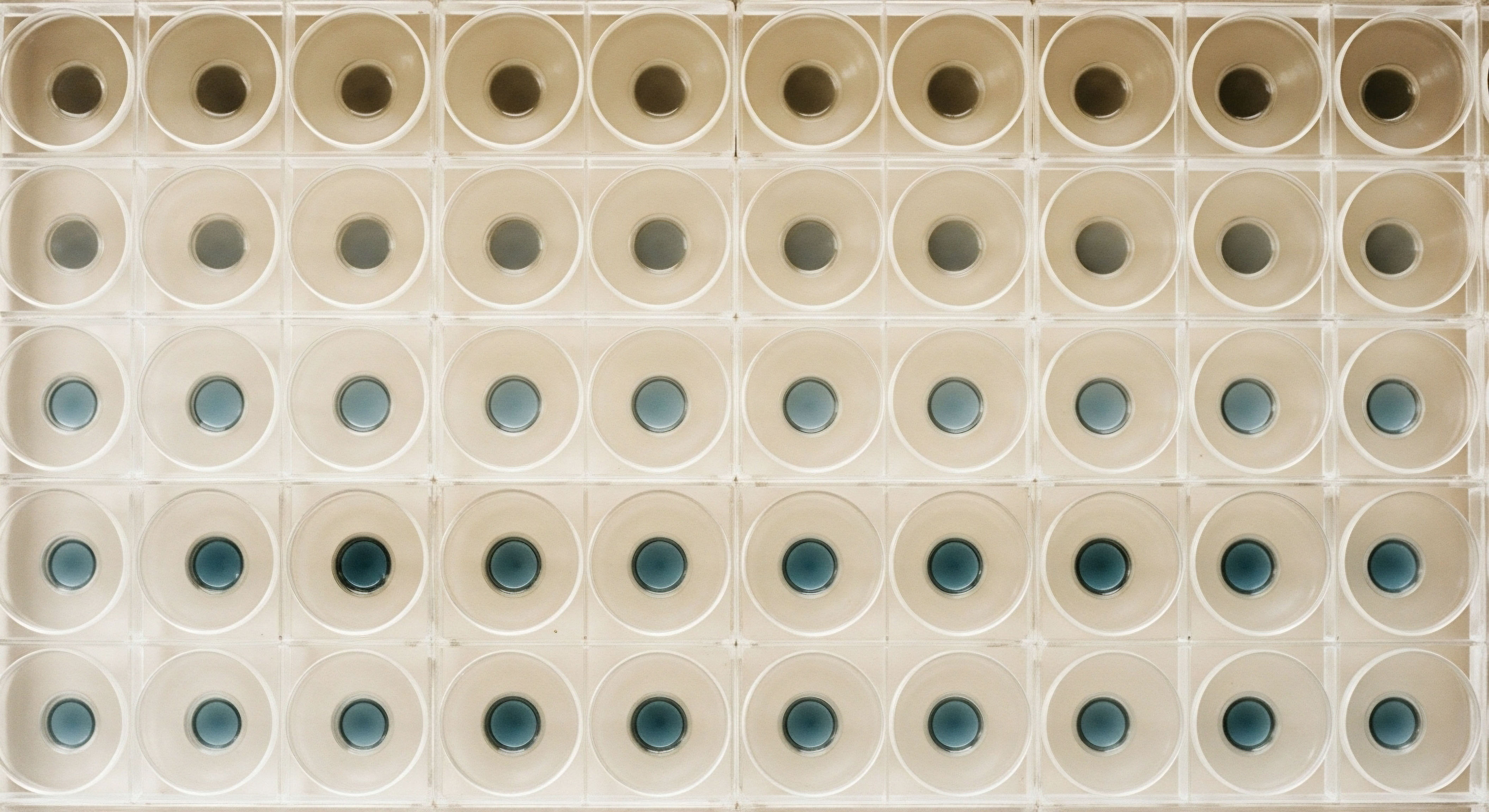

Compounding pharmacies operate under a different set of standards. Their primary oversight comes from state Boards of Pharmacy, which set and enforce rules for pharmacy practice within their jurisdiction. The U.S. Pharmacopeia (USP) creates standards that serve as a benchmark for quality. Two of the most important USP chapters for compounding are:

- USP Chapter <795> This chapter provides standards for compounding non-sterile preparations, such as creams, capsules, or oral solutions. It includes guidance on ingredient sourcing, facility requirements, and record-keeping to ensure the final product is prepared safely and accurately.

- USP Chapter <797> This chapter outlines the much stricter requirements for sterile compounding, which applies to injectable medications like Testosterone Cypionate, Gonadorelin, or peptide therapies. It mandates specific cleanroom environments, air quality controls, personnel garbing procedures, and sterility testing to prevent microbial contamination, a significant risk with injectable drugs.

While these USP standards are robust, their enforcement has historically been the responsibility of state boards, leading to variability. The landscape changed significantly with the Drug Quality and Security Act (DQSA) of 2013. This federal law clarified the FDA’s authority and created a new category of compounder, the “outsourcing facility.”

How Do 503a and 503b Facilities Differ?

The DQSA established two distinct types of compounding entities, each with its own set of rules. Understanding this distinction is vital, as it directly relates to the oversight applied to your medication.

A 503A facility is a traditional compounding pharmacy. It prepares customized medications based on a valid prescription for a specific, identified patient. These pharmacies are regulated primarily by state boards and must comply with USP standards. They are exempt from federal CGMP requirements, FDA new drug approval processes, and certain labeling rules. This model is designed for the classic patient-pharmacist-prescriber relationship.

A 503B facility, or “outsourcing facility,” is a different entity. These facilities can compound larger batches of medications, with or without prescriptions, to be sold to healthcare providers. Because they operate more like a manufacturer, they are held to a higher standard.

Outsourcing facilities must voluntarily register with the FDA and are required to comply with full CGMP requirements, similar to a traditional pharmaceutical manufacturer. They are subject to routine FDA inspections. This category was created to provide a more reliable source of compounded medications for hospitals and clinics that need sterile preparations in larger quantities, especially for drugs that are in shortage.

The distinction between a 503A pharmacy and a 503B outsourcing facility determines the level of federal manufacturing oversight applied to a compounded medication.

For your hormonal health journey, this means a compounded prescription for a low-dose testosterone cream would likely come from a 503A pharmacy. A sterile injectable peptide like Sermorelin or a specific TRT formulation might be sourced from either a 503A pharmacy that meets USP <797> standards or a 503B outsourcing facility operating under CGMP. The choice often depends on your physician’s sourcing protocols and their assessment of the pharmacy’s quality standards.

| Standard | FDA-Approved Drug Manufacturer | 503B Outsourcing Facility | 503A Compounding Pharmacy |

|---|---|---|---|

| Primary Oversight | U.S. Food and Drug Administration (FDA) | U.S. Food and Drug Administration (FDA) | State Boards of Pharmacy |

| Governing Standard | Current Good Manufacturing Practices (CGMP) | Current Good Manufacturing Practices (CGMP) | USP Chapters (e.g. <795>, <797>) |

| Patient Requirement | No individual prescription required for manufacturing. | Can produce for office stock without patient-specific prescriptions. | Requires a valid prescription for an individual patient. |

| FDA Registration | Mandatory | Voluntary (but required to operate as a 503B) | Not applicable |

| FDA Approval | Required before marketing. | Exempt from new drug approval process. | Exempt from new drug approval process. |

Academic

A sophisticated approach to personalized hormonal therapy demands a granular understanding of pharmacology and systems biology. The clinical decision to use an FDA-approved versus a compounded medication extends beyond simple availability. It involves a deep consideration of pharmacokinetics and pharmacodynamics, specifically how manufacturing variables can influence a drug’s bioavailability, potency, and sterility, thereby affecting the delicate balance of the hypothalamic-pituitary-gonadal (HPG) axis and other endocrine feedback loops.

The core value of the FDA’s CGMP framework is the minimization of variability. For a hormone like testosterone, consistency is paramount. The therapeutic window is relatively narrow, and fluctuations in serum levels can lead to a cascade of undesirable effects, from mood lability and gynecomastia (due to aromatization into estrogen) to an incomplete resolution of hypogonadal symptoms.

CGMP standards for an approved product like Testosterone Cypionate mandate rigorous testing for potency (the amount of active pharmaceutical ingredient, or API) and the absence of impurities. Stability testing ensures that the hormone does not degrade over its shelf life, guaranteeing that the 200mg/ml concentration listed on the vial is what is delivered into the tissue throughout its expiration date. This level of assurance is the bedrock of predictable clinical outcomes.

What Are the Biochemical Implications of Manufacturing Variables?

When we shift the lens to compounded medications, the biochemical considerations become more complex. While high-quality compounding pharmacies adhere strictly to USP standards, the nature of customized preparation introduces variables that are absent in large-scale, standardized manufacturing.

- Potency and Homogeneity ∞ In a compounded topical cream containing testosterone, ensuring that the API is uniformly distributed throughout the base is a critical challenge. A lack of homogeneity can lead to significant dose variations with each application. A patient might receive 5mg one day and 15mg the next, despite applying the same volume of cream. This variability can wreak havoc on the HPG axis, causing erratic signaling and preventing the establishment of a stable physiological state. While 503B facilities under CGMP have processes to validate homogeneity, this can be a more significant variable in smaller-scale 503A preparations.

- Bioavailability of Active Ingredients ∞ The choice of base ingredients (excipients) in a compounded formulation can profoundly impact the absorption and bioavailability of the active hormone. For transdermal applications, the vehicle determines the rate and extent of the drug’s penetration through the stratum corneum. Different base creams have different pharmacokinetic profiles. An experienced compounding pharmacist can select a base to optimize absorption, but this introduces a layer of complexity absent from an FDA-approved product, which has undergone extensive pharmacokinetic studies with its specific formulation.

- Sterility and Endotoxins in Injectables ∞ For sterile compounded injectables, such as peptide therapies (e.g. Sermorelin, Ipamorelin) or TRT protocols, the risks are magnified. USP <797> provides a framework for preventing microbial contamination. A more subtle threat is the presence of bacterial endotoxins. These are fragments of bacterial cell walls that can remain even after sterilization and can provoke a significant inflammatory response in the body. CGMP for FDA-approved injectables includes stringent limits and testing for endotoxins. While 503B facilities also test for this, the risk profile can differ from that of a large-scale manufacturer, and it remains a critical quality attribute that the prescribing physician must consider when selecting a compounding pharmacy. Poor compounding practices can result in contamination or incorrect dosing, which can lead to serious patient injury.

The Regulatory Science of Bulk Ingredients

A further layer of academic scrutiny involves the origin of the active pharmaceutical ingredients (APIs) themselves. Compounding pharmacies must source their bulk drug substances from FDA-registered facilities. These facilities are inspected by the FDA to ensure they meet quality standards for producing the raw chemical.

The FDA also maintains lists of bulk substances that can be used in compounding. This oversight provides a foundational layer of safety. However, the journey from a pure chemical powder to a final, sterile, and stable medicinal preparation involves numerous steps where quality can be compromised.

The CGMP framework of a pharmaceutical manufacturer or a 503B facility is designed to control every one of those steps, while the USP framework for a 503A pharmacy provides guidance for best practices. The ultimate quality of a compounded medication is therefore intrinsically linked to the diligence, expertise, and technological capability of the specific pharmacy preparing it.

This is why a clinician’s trust in a particular compounding pharmacy is built over time, based on consistent patient outcomes and a deep understanding of the pharmacy’s quality control processes.

The scientific integrity of a hormonal protocol rests on the chemical purity, precise concentration, and biological availability of the active molecules, all of which are directly influenced by manufacturing standards.

This detailed analysis reveals that the choice between an approved and a compounded medication is a clinical decision that balances the need for therapeutic personalization against the inherent variables in manufacturing processes. For a patient on a complex protocol involving peptides like PT-141 for sexual health or a tailored TRT regimen including Gonadorelin and Anastrozole, the partnership between an informed physician and a high-quality compounding pharmacy is essential to achieving the desired physiological outcome safely and effectively.

References

- U.S. Food and Drug Administration. “Compounding and the FDA ∞ Questions and Answers.” FDA.gov, 15 November 2024.

- Gionfriddo, Michael R. and Cole, Spencer. “FDA oversight of drug manufacturing and compounding ∞ A comparison.” Brookings Institution, 19 December 2024.

- “Compounded Medications ∞ Are They Legal, FDA-Approved, and Covered by Insurance?” GoodRx Health, 6 September 2024.

- “Drug Compounding & US FDA Regulatory Compliance.” AXSource, 13 May 2024.

- “Drug Compounding Standards in the U.S.” Empower Pharmacy, 2024.

Reflection

You began this exploration seeking clarity on the medications that form the foundation of your health protocol. This knowledge of manufacturing standards, regulatory oversight, and the science of formulation is more than academic. It is a powerful tool for self-advocacy.

It transforms the conversation with your clinician from a passive acceptance of a prescription to an active, collaborative partnership. You are now equipped to ask more precise questions, to understand the rationale behind each therapeutic choice, and to appreciate the profound connection between a medication’s origin and its effect on your body’s intricate systems.

Your personal health narrative is unique. The symptoms you experience, the goals you set, and your body’s response to therapy are all yours alone. The path to reclaiming your vitality is not about finding a universal answer; it is about building a personalized strategy. This information serves as your map and compass.

It empowers you to navigate your options with confidence, to engage with your clinical team on a deeper level, and to take ownership of the process. The ultimate goal is a state of well-being that is defined not by a lab report alone, but by the way you feel and function in your daily life. This understanding is the first, most important step on that path.

Glossary

food and drug administration

current good manufacturing practices

cgmp

testosterone cypionate

compounded medications

peptide therapy

compounded medication

endocrine system

good manufacturing practices

u.s. pharmacopeia

outsourcing facility

usp standards

dqsa

compounding pharmacy

503a facility

503b outsourcing facility

503a pharmacy

bioavailability

active pharmaceutical ingredient