Fundamentals

You may have encountered peptide therapies in your search for optimizing your health, seeking to address persistent symptoms that feel deeply personal yet are frustratingly difficult to pin down. Perhaps you’ve noticed the significant investment required for these protocols and wondered about the reasons behind their cost.

The price of a therapeutic peptide Meaning ∞ A therapeutic peptide is a short chain of amino acids, typically 2 to 50 residues, designed to exert a specific biological effect for disease treatment or health improvement. is a direct reflection of the immense biological and chemical complexity involved in its creation. These molecules are not simple chemicals mixed in a beaker; they are meticulously constructed biological signals, designed to interface with your body’s own communication networks with incredible precision.

Understanding the journey of a peptide from a sequence on a computer screen to a therapeutic tool in a clinician’s hands provides a powerful lens through which to view your own health journey. It is a story of microscopic engineering, where every step is governed by the demand for purity and biological integrity.

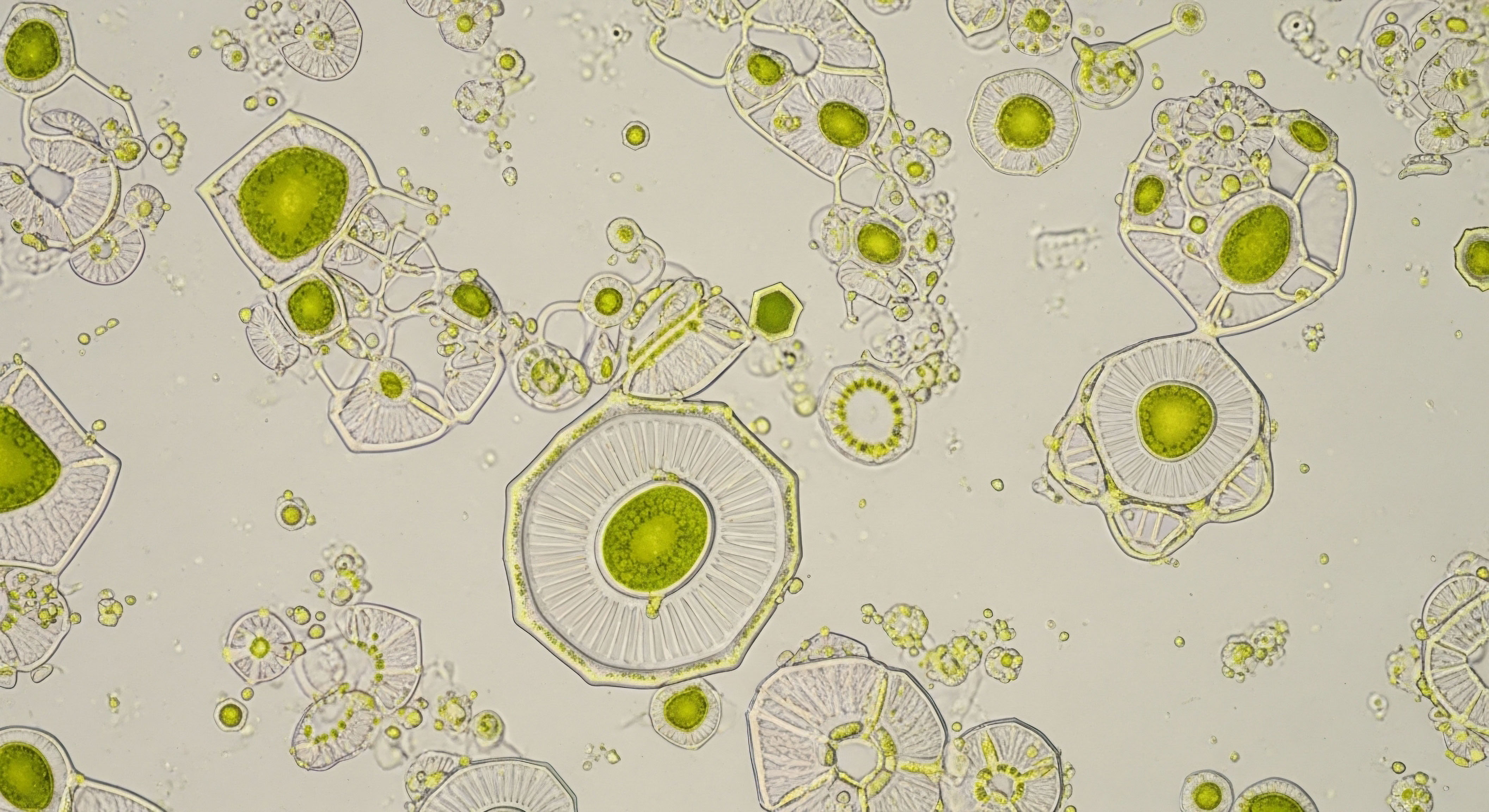

At its heart, a peptide is a short chain of amino acids, the fundamental building blocks of proteins. Think of them as specialized messengers, crafted to deliver a very specific instruction to a very specific recipient within your body.

Your own biology is constantly producing and using peptides to regulate countless processes, from managing inflammation to triggering the release of hormones. When we use peptide therapy, we are introducing a highly refined messenger to supplement or restore a biological conversation that has been diminished or disrupted by age, stress, or metabolic changes.

The goal is to speak the body’s native language. To do this effectively, the therapeutic peptide must be an exact replica of the intended messenger, free from any confusing or contradictory signals.

The Blueprint for a Biological Messenger

The journey begins with a blueprint ∞ the specific sequence of amino acids Meaning ∞ Amino acids are fundamental organic compounds, essential building blocks for all proteins, critical macromolecules for cellular function. that defines the peptide’s function. This sequence determines the peptide’s three-dimensional shape, which in turn dictates how it will bind to its target receptor on a cell surface.

This binding event is like a key fitting into a lock; a perfect fit initiates a specific biological response, while an imperfect fit does nothing or, in some cases, can block the lock. The first challenge, therefore, is to assemble these amino acid “beads” onto a “string” in the correct order, without a single one out of place.

A peptide that is thirty amino acids long requires thirty precise chemical reactions, each one building upon the last in a fragile, growing chain.

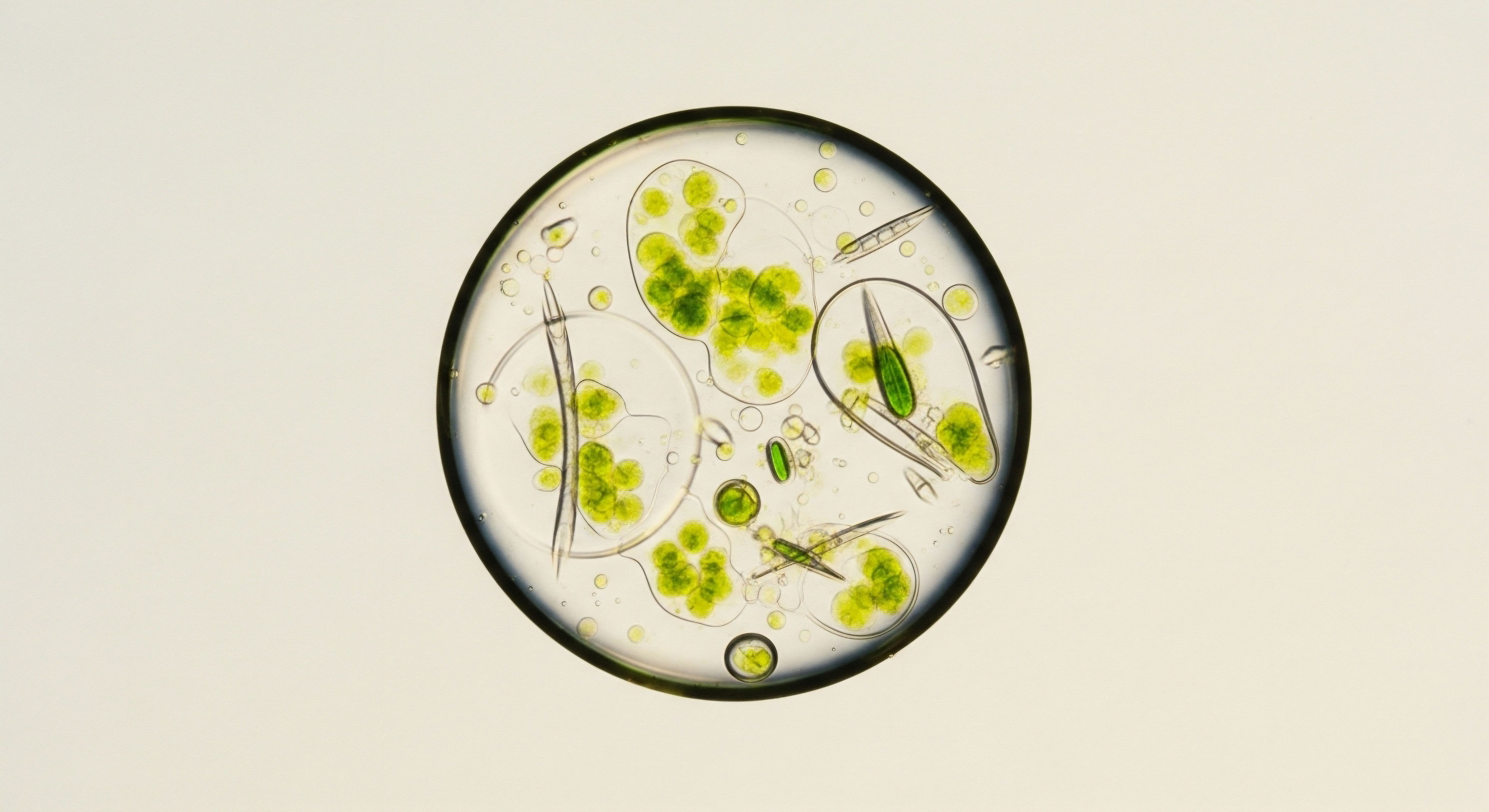

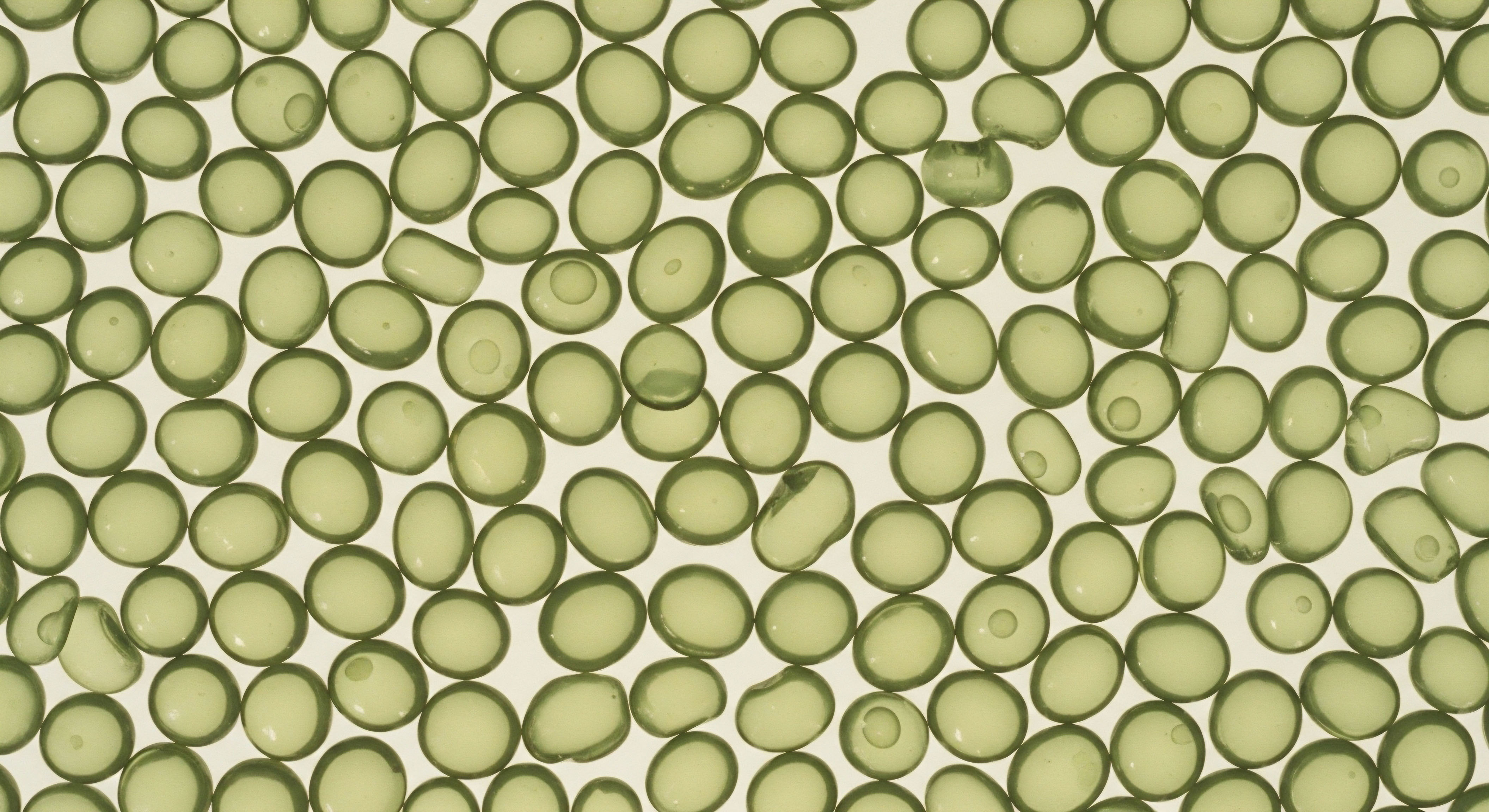

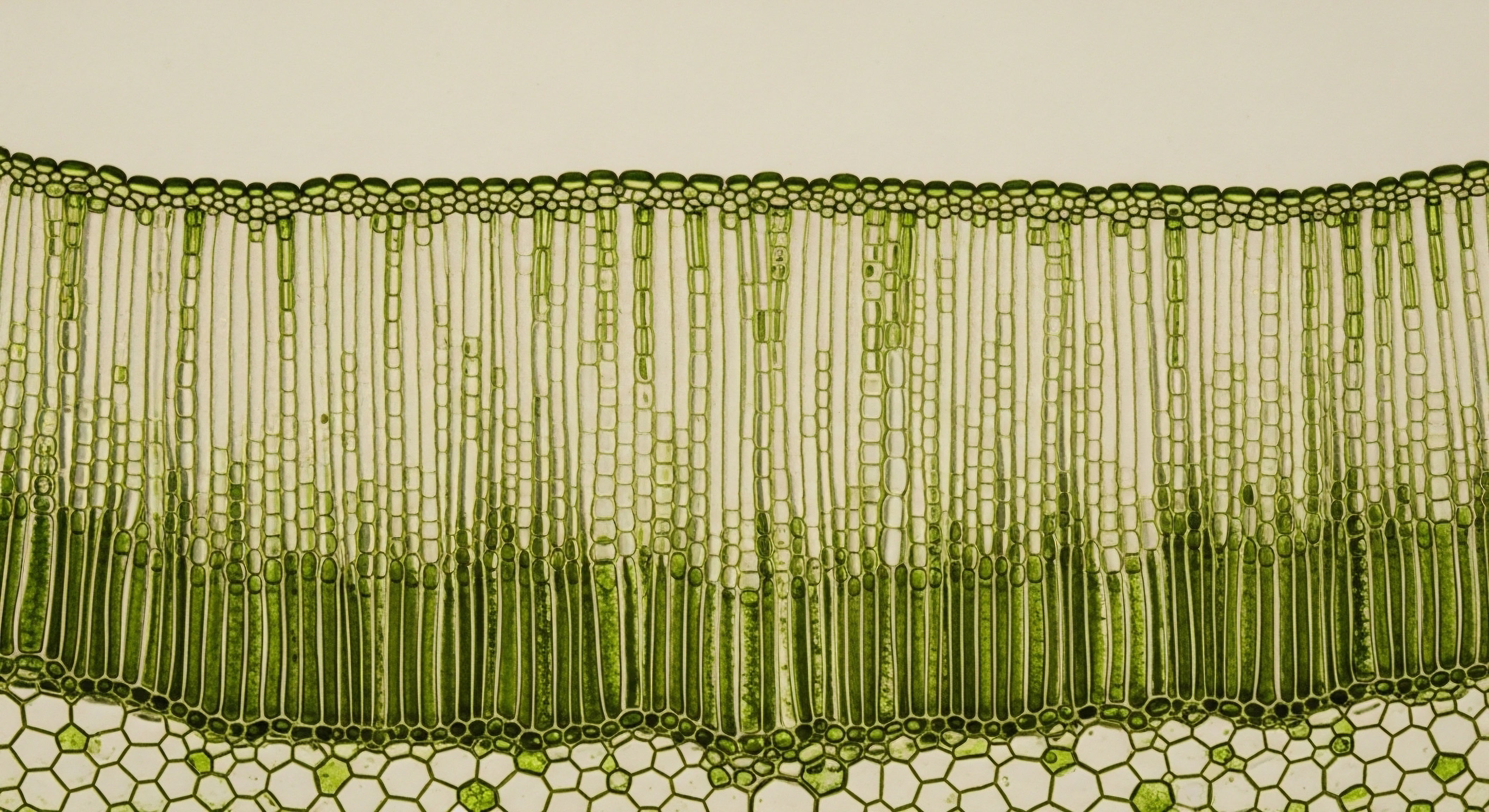

This assembly process is known as peptide synthesis. The most prevalent method used today is called Solid-Phase Peptide Synthesis, or SPPS. This technique anchors the first amino acid of the chain to a solid, microscopic resin bead. From this anchor point, the peptide is built one amino acid at a time in a repeating cycle of chemical steps.

Each cycle involves adding the next amino acid in the sequence and forming a strong chemical bond, known as a peptide bond. This process occurs inside a specialized instrument called a peptide synthesizer, which automates the delivery of the required chemical reagents and the washing steps needed to remove excess materials after each addition.

The elegance of SPPS lies in its ability to control the construction process, but this control comes at a cost in materials, time, and the potential for error with each added link.

Why Purity Is the Bedrock of Peptide Therapy

Imagine sending a critical message, but the ink is smudged, and extra, random words have been added. The recipient might be confused, misinterpret the instruction, or discard the message entirely. In the world of your cells, this is what happens when a peptide therapy Meaning ∞ Peptide therapy involves the therapeutic administration of specific amino acid chains, known as peptides, to modulate various physiological functions. is impure.

The manufacturing process, despite its precision, can generate a number of incorrect molecules alongside the correct one. These are known as impurities. They can be peptides with a missing amino acid (deletion sequences), an extra one (insertion sequences), or amino acids that have been chemically altered during the harsh synthesis process.

These impurities are the central reason for the high cost of therapeutic peptides. A vial of “research grade” peptide might contain a significant percentage of these molecular errors. While this may be acceptable for preliminary lab experiments, it is entirely unacceptable for human use. Impurities can have several negative consequences:

- Reduced Efficacy ∞ If a significant portion of the vial contains incorrect peptides, the dose of the active, correct peptide is lower than intended, diminishing the therapeutic effect.

- Altered Biological Signals ∞ Some impurities can bind to the target receptor without activating it, effectively blocking the correct peptide from doing its job. In some cases, an impurity can even trigger an entirely different and unwanted biological response.

- Immunogenic Reactions ∞ The human immune system is exquisitely designed to recognize foreign or malformed proteins. An impure peptide preparation can be flagged by the immune system, leading to an inflammatory response or the development of antibodies against the therapy, rendering it ineffective and potentially causing adverse effects.

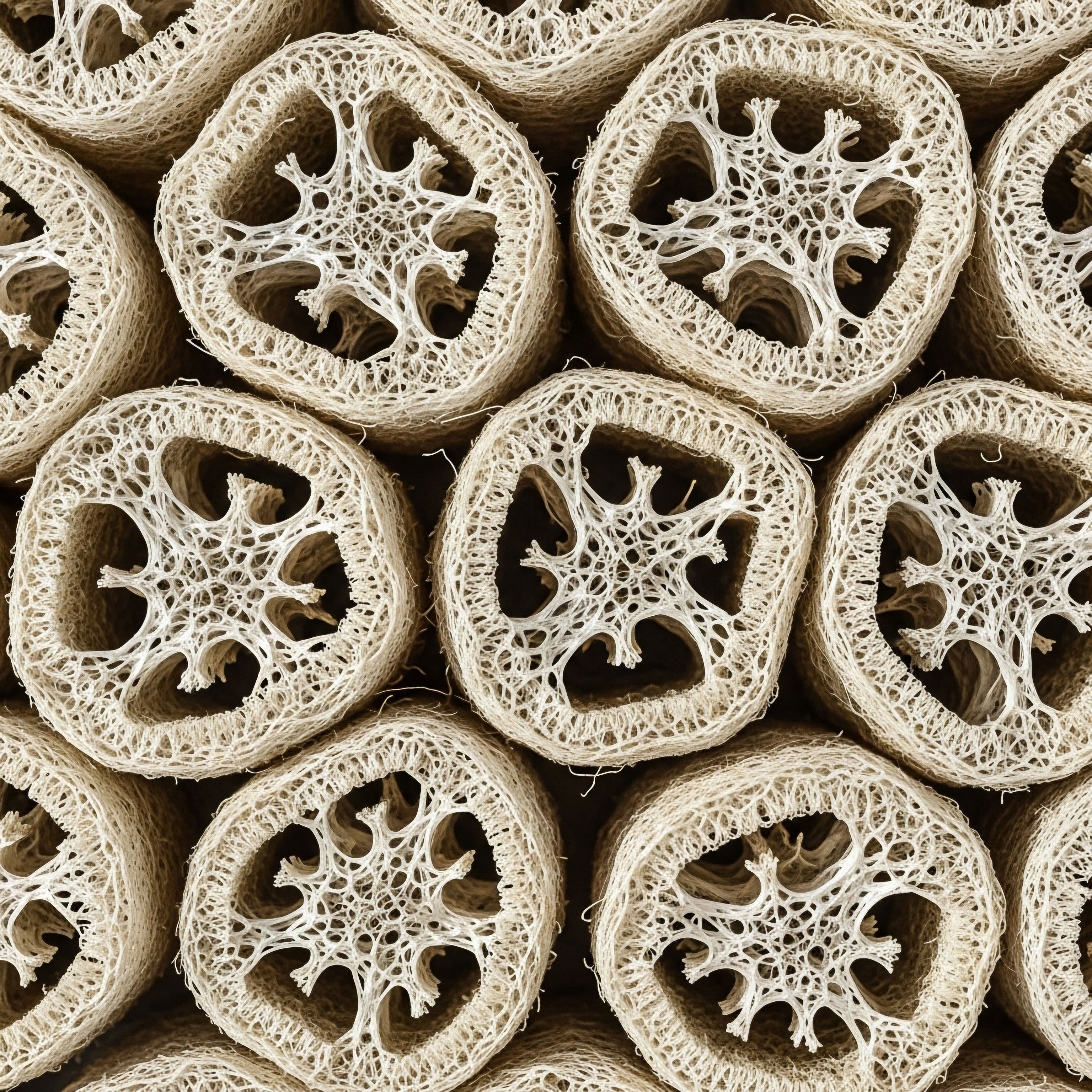

Therefore, the bulk of the manufacturing process and its associated cost is dedicated to purification. After the peptide is synthesized and cleaved from its resin bead, it exists as a “crude” mixture. This mixture then undergoes a rigorous purification process, most commonly a technique called High-Performance Liquid Chromatography Meaning ∞ High-Performance Liquid Chromatography, commonly known as HPLC, is an advanced analytical chemistry technique used to separate, identify, and quantify individual components within a complex liquid mixture. (HPLC).

HPLC separates the correct peptide from the swarm of impurities based on their distinct chemical properties. This is a meticulous, time-consuming, and expensive process that requires sophisticated equipment and highly skilled technicians. Achieving the greater than 99% purity required for clinical use means discarding a significant portion of the initially synthesized material, which directly increases the cost of the final, purified product.

The price you see is a reflection of this uncompromising commitment to providing your body with a clear, precise, and safe biological instruction.

The cost of a therapeutic peptide is fundamentally tied to the microscopic precision required to build and purify a safe and effective biological signal for the body.

This initial look into the world of peptide manufacturing reveals a core truth ∞ creating a molecule that can seamlessly integrate into the complex symphony of human physiology is a profound scientific and technical challenge. The financial investment is a direct consequence of the steps required to meet that challenge, ensuring the final product is a clean, potent, and reliable tool for health optimization.

Intermediate

Understanding that peptide therapy’s cost is rooted in the pursuit of purity opens the door to a deeper appreciation of the manufacturing process itself. This is where the abstract concept of “complexity” translates into tangible, resource-intensive steps.

For anyone on a journey of hormonal or metabolic recalibration, knowing the “how” of this process provides a powerful context for the protocols you may be considering. The journey from a chemical blueprint to a vial of therapeutic peptide is governed by a set of exacting standards known as Good Manufacturing Practices Meaning ∞ Good Manufacturing Practices (GMP) represent a regulatory framework and a set of operational guidelines ensuring pharmaceutical products, medical devices, food, and dietary supplements are consistently produced and controlled according to established quality standards. (GMP).

Adherence to these standards elevates the entire production process to a clinical level, creating a vast financial and operational gap between a peptide made for research and one destined for human therapy.

The manufacturing process is a multi-stage endeavor, with each stage presenting its own set of challenges that influence the final cost and the timeline for market entry. We can deconstruct this process to see how these complexities accumulate, starting with the foundational choice of synthesis strategy and moving through the exacting realities of purification and quality control under GMP guidelines.

A Deeper Look into Synthesis Methodologies

While Solid-Phase Peptide Synthesis Meaning ∞ Solid-Phase Peptide Synthesis (SPPS) is a robust chemical method for creating peptides by sequentially adding amino acid building blocks to a growing chain that is anchored to an insoluble polymeric support, typically a resin bead. (SPPS) is the workhorse of the industry, the specific choices made within this methodology have significant cost implications. The process is a meticulous cycle of chemical reactions performed on a solid resin support, allowing for easy removal of waste products. Let’s break down a single coupling cycle:

- Deprotection ∞ The amino acid chain anchored to the resin has a temporary “protecting group” on its end. This chemical cap prevents unwanted reactions. To add the next amino acid, this cap must be removed, typically using a chemical like piperidine dissolved in a solvent such as N,N-dimethylformamide (DMF). The use and subsequent disposal of these chemicals contribute to both material and environmental costs.

- Activation and Coupling ∞ The next amino acid to be added is chemically “activated.” This activation step makes its carboxyl end highly reactive, allowing it to form a strong peptide bond with the newly deprotected end of the growing chain. This step requires specialized, and often expensive, coupling reagents. The efficiency of this reaction is critical; an incomplete coupling results in a “deletion sequence” impurity, where an amino acid is missing from the final peptide. To ensure the reaction goes to completion, an excess of the expensive, protected amino acid and coupling reagents is often used, with the unused portion being washed away and discarded, adding to the cost.

- Washing ∞ After each deprotection and coupling step, the resin must be thoroughly washed with solvents to remove all excess reagents and byproducts. This step is repeated multiple times, consuming large volumes of high-purity solvents which are costly to purchase and dispose of in an environmentally responsible manner. Inadequate washing can leave behind chemicals that interfere with subsequent steps, leading to a cascade of impurity formation.

This entire cycle repeats for every single amino acid in the peptide chain. For a peptide like CJC-1295 (29 amino acids) or Tesamorelin (44 amino acids), this means dozens of cycles, each with its own material costs and potential for introducing errors. The longer and more complex the peptide, the lower the overall yield of the correct final product, as errors accumulate with each step. This cumulative loss is a primary driver of cost for longer peptides.

The iterative nature of peptide synthesis, with its reliance on expensive reagents and large solvent volumes, means that cost and complexity scale directly with the length of the amino acid chain.

Comparing Synthesis Strategies SPPS Vs LPPS

An alternative to SPPS is Liquid-Phase Peptide Synthesis Meaning ∞ Peptide synthesis is the biochemical process by which amino acids are joined together by peptide bonds to form longer peptide chains, a fundamental step in the creation of proteins and other biologically active peptides within living systems or through laboratory methods. (LPPS), where the entire process occurs in a solution. While less common for custom peptides, it has advantages for producing very large quantities of a specific peptide once a process is established. The two methods present a trade-off between flexibility and scalability.

| Feature | Solid-Phase Peptide Synthesis (SPPS) | Liquid-Phase Peptide Synthesis (LPPS) |

|---|---|---|

| Principle | The peptide chain is built on an insoluble solid resin support. Reagents are flowed through a column, and excess is washed away. | All reactions occur in a homogenous solution. Intermediates must be isolated and purified after each step or every few steps. |

| Key Advantage | Ease of automation and purification of intermediates. The process is faster for creating novel or complex peptides on a small to medium scale. | Highly scalable for massive production volumes of a specific peptide. It can be more cost-effective at an industrial scale due to lower raw material costs. |

| Primary Challenge | High consumption of expensive reagents and solvents. Yield decreases significantly with longer peptides. Scaling up can be difficult and costly. | Technically very challenging. Requires purification after each step, which is time-consuming and can lead to product loss. Less suited for flexible or custom synthesis. |

| Cost Driver | Cost of protected amino acids, specialized coupling reagents, and large volumes of high-purity solvents. The cost of the solid resin support itself. | Labor-intensive purification steps and the capital investment in large-scale reactor equipment. Process development is lengthy and expensive. |

The GMP Mandate from Lab Bench to Clinic

What truly separates a research peptide from a therapeutic one is the implementation of Good Manufacturing Practices (GMP). GMP is a system of regulations enforced by agencies like the FDA that ensures a product is produced and controlled according to strict quality standards. Complying with GMP is a massive undertaking that impacts every facet of production and is a principal driver of the final price.

Key aspects of GMP in peptide manufacturing include:

- Facility and Equipment ∞ GMP requires manufacturing to occur in a highly controlled environment, often within a “cleanroom.” Air quality, temperature, and humidity are strictly regulated to prevent contamination. All equipment must be qualified and validated, meaning it is proven to operate as intended, consistently. This requires extensive documentation and regular, costly maintenance and calibration.

- Raw Material Control ∞ Under GMP, every raw material, from the simplest solvent to the most complex amino acid derivative, must be sourced from a qualified vendor and undergo rigorous identity and purity testing before it can be used in production. This ensures that impurities are present from the very beginning of the process.

- Process Validation ∞ The entire manufacturing process must be validated. This means the manufacturer must prove through extensive testing and documentation that their specific process consistently produces a peptide of the required purity, potency, and quality. A failure in a single batch during development can cost millions of dollars and cause significant delays.

- Documentation and Traceability ∞ Every single action, every material used, and every test performed must be meticulously documented in batch records. This creates a complete, traceable history of each vial of peptide, from raw materials to final product. This level of record-keeping is labor-intensive and requires robust quality management systems.

The cost of establishing and maintaining a GMP-compliant facility is enormous, and these overhead costs are factored into the price of every peptide produced. This is a primary reason why a peptide intended for human use can be ten to one hundred times more expensive than a chemically identical peptide sold for research purposes only. The higher price buys an assurance of safety, purity, and consistency that is absent in the non-GMP environment.

Academic

The transition of a peptide from a promising molecular concept to a clinically available therapy is governed by a complex interplay of synthetic chemistry, analytical science, and stringent regulatory oversight. For the clinician and the informed patient, understanding these deep complexities provides the ultimate context for the value proposition of peptide therapies.

The final price and the often-protracted timeline for market entry are direct outputs of a system designed to ensure absolute safety and efficacy. This system forces manufacturers to solve profound molecular challenges and demonstrate mastery over their process to a degree unparalleled in many other areas of chemical manufacturing. The central nexus of this challenge is the identification, characterization, and control of process-related impurities.

What Are the Molecular Hurdles in Peptide Synthesis?

The idealized vision of peptide synthesis, a simple stringing of amino acid beads, quickly gives way to a more complex reality at the molecular level. Certain amino acid sequences, known as “difficult sequences,” present formidable challenges to the standard SPPS protocol.

These sequences can cause the growing peptide chain to fold back on itself and aggregate on the resin bead, even during synthesis. This aggregation shields the end of the chain, preventing the next amino acid from being added efficiently.

This leads to a high proportion of truncated sequences and a dramatic drop in the yield of the correct, full-length peptide. Overcoming this requires specialized chemical cocktails, elevated temperatures (microwave-assisted SPPS), or alternative solvents, all of which add cost and complexity to the process.

Furthermore, the incorporation of non-proteinogenic amino acids, which are often used to enhance a peptide’s stability or binding affinity, introduces another layer of difficulty. These custom building blocks are themselves expensive to produce and may require unique coupling protocols that must be developed and validated, further increasing the cost and timeline of process development.

The chemical integrity of each amino acid is also at risk. The harsh chemicals used for deprotection can cause unintended side reactions on the “side chains” of certain amino acids. For example, the amino acid asparagine can deamidate, and aspartic acid can form a succinimide ring, both creating structurally distinct and biologically inactive or altered impurities that are very difficult to separate from the target peptide.

The Anatomy of an Impurity Profile

A peptide drug substance is defined not just by the main compound but by its unique impurity profile. Regulatory bodies like the FDA require an exhaustive characterization of this profile. The cost of this deep analysis is substantial, requiring a battery of sophisticated analytical techniques.

Any impurity present above a certain threshold (typically 0.10% to 0.5%) must be identified, and if it exceeds a higher threshold (often 1.0%), its biological activity and potential toxicity must be qualified through additional studies. This is a monumental task that adds significant expense and time to the development process.

| Impurity Class | Origin in Manufacturing Process | Potential Biological Consequence | Primary Analytical Detection Method |

|---|---|---|---|

| Deletion Sequences | Incomplete coupling or deprotection steps during SPPS, often due to steric hindrance or peptide aggregation on the resin. | Lowered efficacy due to reduced concentration of the active peptide. May act as a competitive antagonist at the target receptor. | Mass Spectrometry (MS) to identify incorrect mass; High-Performance Liquid Chromatography (HPLC) for separation. |

| Insertion Sequences | Incomplete washing allowing a residual activated amino acid to be incorporated out of sequence, or double addition of an amino acid. | Altered three-dimensional structure, leading to loss of binding affinity or potentially novel, off-target effects. | Mass Spectrometry (MS) to detect the addition of an extra amino acid’s mass. |

| Racemization/Epimerization | The chiral center of an amino acid (its “handedness”) inverts during the activation/coupling step. This is more common with certain amino acids like histidine and cysteine. | The resulting diastereomer may be biologically inactive or have a completely different pharmacological profile. It can be difficult to separate chromatographically. | Chiral Chromatography; Advanced Nuclear Magnetic Resonance (NMR) Spectroscopy. |

| Oxidation | Amino acids like methionine and tryptophan are susceptible to oxidation from exposure to air or trace peroxides in solvents. | Can reduce or eliminate biological activity by altering the peptide’s conformation or ability to bind to its receptor. | HPLC and Mass Spectrometry (detects mass increase of 16 Da per oxygen atom). |

| Residual Protecting Groups | Incomplete final cleavage or deprotection steps, leaving chemical groups used during synthesis attached to the peptide’s side chains. | Can significantly alter the peptide’s solubility, stability, and biological function, and may increase immunogenicity. | Mass Spectrometry to detect higher-than-expected mass; HPLC. |

How Does Regulation Translate Purity into Price?

The entire regulatory approval Meaning ∞ Regulatory approval is the official authorization from a governmental health authority, like the FDA or EMA, allowing a pharmaceutical product, medical device, or diagnostic tool to be marketed publicly. process for a new peptide therapeutic is predicated on the manufacturer’s ability to demonstrate consistent control over this impurity profile. This is the essence of the Chemistry, Manufacturing, and Controls (CMC) section of a New Drug Application (NDA). The investment required to generate the data for this section is staggering. It includes:

- Analytical Method Validation ∞ The HPLC and MS methods used to assess purity must themselves be validated. This involves proving they are accurate, precise, reproducible, and robust ∞ a process that can take months and significant resources.

- Stability Studies ∞ Manufacturers must conduct long-term stability studies, storing the peptide under various temperature and humidity conditions for months or even years. They must periodically test these samples to prove that the peptide does not degrade and that new impurities do not form over time. These studies dictate the shelf-life of the product and are a major bottleneck in the approval timeline.

- Toxicology of Impurities ∞ If a specific impurity is consistently present above the qualification threshold, the manufacturer may be required to synthesize that impurity in its pure form and conduct toxicological studies on it to prove it is safe. This is effectively a mini-drug development program for an unwanted byproduct.

The cumulative cost of these activities can run into many millions of dollars. This immense financial barrier is a primary reason why smaller companies may struggle to bring novel peptide therapies to market, even if the science is promising.

It also explains why the final price of an approved peptide drug must account for these extensive development and regulatory costs, in addition to the direct costs of manufacturing each batch. The market entry is a high-stakes gauntlet where molecular precision and regulatory compliance are inextricably linked, and the price reflects the cost of successfully navigating it.

The regulatory pathway for peptide therapeutics functionally mandates a multi-million dollar investment in analytical science to prove that a manufacturing process can consistently control the complex landscape of molecular impurities.

Ultimately, the complexities of manufacturing are the primary determinant of a peptide’s price and its accessibility. From the fundamental chemistry of the peptide bond to the global regulatory frameworks ensuring patient safety, each layer of complexity adds cost and time. This investment is the bedrock upon which the promise of peptide therapy is built, ensuring that the molecules used to recalibrate our biology are as pure, potent, and safe as modern science can make them.

References

- De Spiegeleer, B. et al. “Related impurities in peptide medicines.” Journal of Pharmaceutical and Biomedical Analysis, vol. 107, 2015, pp. 360-374.

- U.S. Department of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research (CDER). “Guidance for Industry ∞ Submitting Chemistry, Manufacturing, and Controls Information for Synthetic Peptide Substances.” 1994.

- Muttenthaler, Markus, et al. “Trends in peptide drug discovery.” Nature Reviews Drug Discovery, vol. 20, no. 4, 2021, pp. 309-325.

- White, P.D. and Collins, J.M. editors. Peptide and Protein Drug Analysis. Marcel Dekker, Inc. 2000.

- Otvos, Laszlo. “Peptide-based Drug Research and Development ∞ Relative Costs, Comparative Value.” Pharmaceutical Outsourcing, 21 May 2014.

- “Solid-Phase Peptide Synthesis ∞ Challenges and Opportunities.” Royal Society of Chemistry, 2013.

- Stawikowski, M. and Fields, G.B. “Introduction to Solid-Phase Peptide Synthesis.” Current Protocols in Protein Science, Chapter 18, Unit 18.1, 2002.

- U.S. Food and Drug Administration. “Guidance for Industry ∞ CGMP for Phase 1 Investigational Drugs.” 2008.

- Blanco-Prieto, M.J. and Fattal, E. editors. Peptide-Based Therapeutics ∞ Formulation and Delivery. Springer, 2019.

- “Development and Regulatory Challenges for Peptide Therapeutics.” International Journal of Toxicology, vol. 40, no. 1, 2021, pp. 16-27.

Reflection

You have now journeyed through the intricate world of peptide manufacturing, from the fundamental act of linking amino acids to the immense regulatory structures that govern clinical therapies. This knowledge does more than simply explain the cost on an invoice; it re-frames it as an investment in biological certainty.

The path to optimizing your health is deeply personal, yet it relies on this impersonal, highly controlled, and resource-intensive process to provide the tools for that recalibration. Your body operates on a system of precise signals, and the science you’ve just explored is dedicated to honoring that precision.

Where Does This Knowledge Guide You?

Consider this understanding a new instrument for navigating your own wellness protocol. When you see the price of a therapy, you can now see the cleanrooms, the chromatography columns, the stability studies, and the unwavering commitment to purity that it represents. This perspective allows you to engage in more informed and substantive conversations with your clinical team.

It equips you to ask questions that move beyond “what does it do?” to “how is its quality ensured?” This is the shift from a passive recipient of care to an active, educated partner in your own health outcome.

The complexities inherent in bringing these powerful molecules to you are substantial, but they exist for a single reason ∞ to protect and enhance your own biological integrity. The final step in this journey of understanding is to turn this knowledge inward. How does this deeper appreciation for the process inform your commitment to your protocol?

How does it shape your perspective on the value of investing in your long-term vitality? The answers are yours alone, but they are now built upon a firmer foundation of scientific truth.