Fundamentals

You feel it. A subtle shift in energy, a change in the way your body responds to exercise, or perhaps a new fogginess that clouds your thoughts. These are not just signs of getting older; they are signals from your body’s intricate communication network, the endocrine system.

This network relies on precise chemical messengers called hormones and peptides to function correctly. When we consider therapeutic peptides ∞ powerful tools for recalibrating this system ∞ we must first understand that their journey to your pharmacy is a testament to incredible scientific precision.

The very complexities that make these molecules so effective are what make their manufacturing and approval a monumental undertaking. A tiny, almost imperceptible change in a peptide’s structure can alter its function entirely, turning a targeted therapeutic into an ineffective or even harmful substance.

This is why regulatory bodies like the Food and Drug Administration (FDA) scrutinize every single step of the process. The timeline for approval is directly linked to the challenge of proving that every single batch of a peptide is identical, pure, and safe. It’s a process born from a deep respect for the body’s delicate biological symphony.

The Blueprint of a Peptide

Peptides are short chains of amino acids, the fundamental building blocks of proteins. Think of them as short, specific instructions sent to different parts of your body. Unlike small-molecule drugs, which have a relatively simple and fixed chemical structure, peptides are larger and more complex.

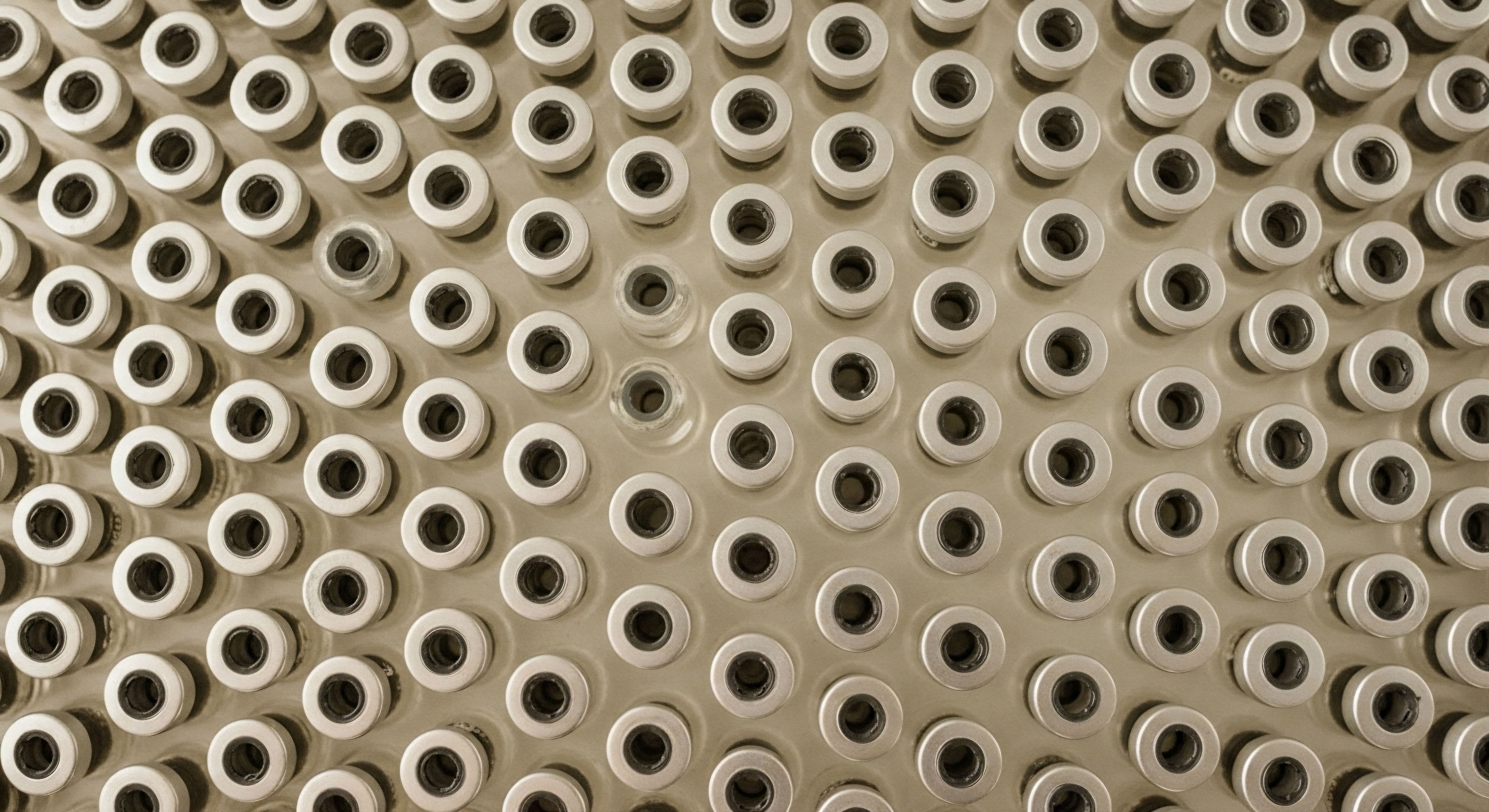

Their manufacturing process, often solid-phase peptide synthesis (SPPS), involves adding amino acids one by one to a growing chain. This sequential process, while precise, opens the door to potential errors. Even a single incorrect amino acid or a bond in the wrong place can create an impurity.

These impurities are a central concern for regulatory agencies because they can have unintended biological effects. Some may be harmless, while others could trigger an immune response or have other adverse effects. The challenge for manufacturers is to create a process that is not only effective but also incredibly consistent, producing a final product that is as pure as possible.

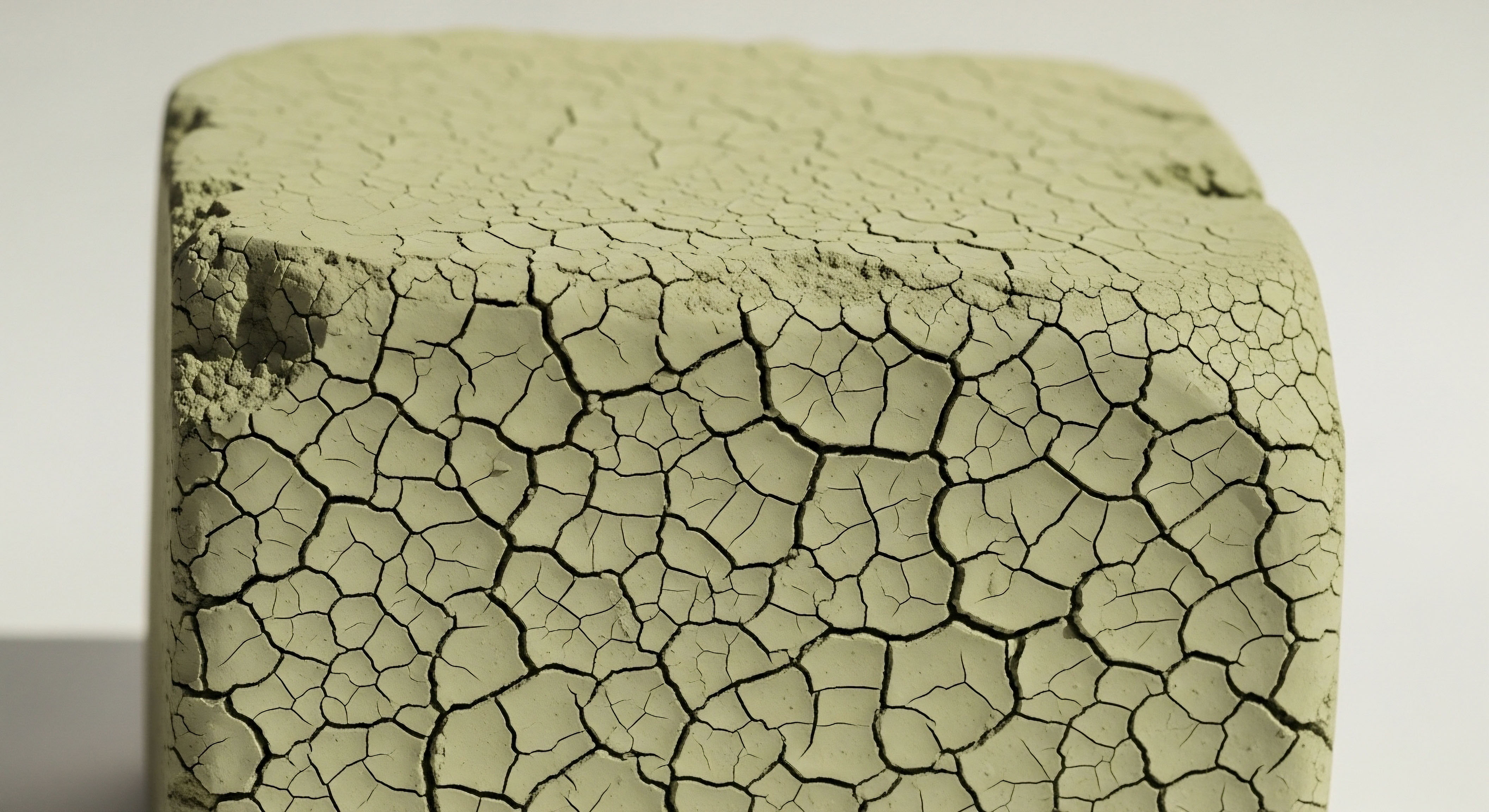

The journey of a peptide from laboratory to clinic is defined by the immense challenge of ensuring its purity and consistency.

Why Purity Dictates the Pace

The core of the regulatory approval process for peptides revolves around a concept known as Chemistry, Manufacturing, and Controls (CMC). This is the detailed dossier that a pharmaceutical company submits to the FDA, outlining every aspect of how the drug is made and tested. For peptides, the CMC data must be exhaustive.

It includes a complete characterization of the peptide’s structure, a detailed description of the manufacturing process, and a thorough analysis of any impurities. Because of the inherent complexity of peptide synthesis, even minor changes in the manufacturing process can lead to different impurity profiles.

This is why regulatory agencies require extensive data to demonstrate that the manufacturing process is well-controlled and that each batch produced is consistent in quality, purity, and strength. Any ambiguity or inconsistency in the CMC data can lead to questions from regulators, requests for more information, and ultimately, delays in the approval timeline.

The time it takes to get a peptide drug to market is a direct reflection of the time it takes to master its manufacturing process to a degree that satisfies the highest safety and quality standards.

Intermediate

For those of you who are already familiar with the basics of hormonal health, you understand that achieving balance is a dynamic process. It is a constant conversation between different systems in your body. Therapeutic peptides are a way to join that conversation, offering specific, targeted messages to guide the system back toward optimal function.

However, the journey of these sophisticated molecules through the regulatory landscape is governed by a lexicon of acronyms and a labyrinth of guidelines. The time it takes for a promising peptide to receive regulatory approval is profoundly influenced by the intricate dance between its manufacturing process and the stringent requirements of agencies like the FDA.

The complexities are not arbitrary bureaucratic hurdles; they are safeguards born from a deep understanding of the peptide’s potential to interact with our biology in powerful ways. Every step of the manufacturing process is a potential source of variation, and it is this variation that regulators seek to understand and control.

The Central Role of CMC in Peptide Approval

At the heart of any drug application is the Chemistry, Manufacturing, and Controls (CMC) section. For peptides, this is where the scientific narrative of the drug is told. It details the precise sequence of amino acids, the method of synthesis, the purification process, and the analytical methods used to confirm the identity and purity of the final product.

Because peptides are synthesized sequentially, the potential for errors is cumulative. These errors can result in impurities, such as deletion sequences (missing an amino acid), insertion sequences (an extra amino acid), or modifications to individual amino acids. The FDA requires manufacturers to identify and characterize these impurities, even at very low levels.

This process can be incredibly challenging, requiring sophisticated analytical techniques like high-performance liquid chromatography (HPLC) and mass spectrometry (MS). The manufacturer must demonstrate that their process consistently produces a peptide with a well-defined impurity profile and that these impurities do not pose a safety risk. Any new or unidentified impurity can trigger a cascade of questions from regulators, extending the approval timeline significantly.

The regulatory approval timeline for a peptide is directly proportional to the manufacturer’s ability to prove absolute control over its complex production process.

How Do Manufacturing Changes Impact Timelines?

Throughout the lifecycle of a drug, from early clinical trials to post-market production, manufacturers may need to make changes to the manufacturing process. This could be to scale up production, improve efficiency, or change a supplier of raw materials. For a simple small-molecule drug, the impact of such changes might be relatively straightforward to assess.

For a peptide, however, even a minor change can have a ripple effect on the final product’s quality and impurity profile. A change in the resin used in SPPS, for instance, could alter the efficiency of the synthesis and lead to a different set of impurities.

As a result, any change to the manufacturing process requires extensive validation studies to demonstrate that the final product remains equivalent to the one that was tested in clinical trials. This process, known as comparability, can be time-consuming and expensive, often requiring new analytical studies and, in some cases, new clinical data. The need to maintain this strict consistency throughout the drug’s lifecycle is a major factor in the overall timeline of peptide development and approval.

The Challenge of Immunogenicity

One of the most significant concerns for regulators is the potential for a peptide or its impurities to trigger an unwanted immune response, a phenomenon known as immunogenicity. Because peptides are similar to molecules naturally found in the body, the immune system can sometimes recognize them as foreign, leading to the production of antibodies.

This can neutralize the therapeutic effect of the drug or, in rare cases, cause serious adverse reactions. Impurities are a particular concern because their novel structures can be more likely to be recognized as foreign by the immune system.

Therefore, regulatory agencies require a thorough immunogenicity risk assessment, which may include in silico (computer-based) modeling, in vitro assays, and clinical monitoring. If a manufacturer changes their process and a new impurity appears, they must assess its potential for immunogenicity. This adds another layer of complexity and another potential source of delay to the regulatory process.

| Manufacturing Complexity | Description | Regulatory Implication |

|---|---|---|

| Synthesis Errors | Incomplete reactions or side reactions during the sequential addition of amino acids. | Generation of peptide-related impurities (e.g. deletions, insertions) that must be identified, quantified, and qualified. |

| Purification Challenges | Difficulty in separating the target peptide from closely related impurities due to similar physicochemical properties. | Requires highly sophisticated and validated purification methods. Residual impurities must be within strict limits. |

| Structural Complexity | Peptides can have complex three-dimensional structures that are critical for their function. | Requires extensive characterization using advanced analytical techniques to ensure the correct structure. |

| Process Changes | Modifications to the manufacturing process after initial approval (e.g. scaling up production). | Requires extensive comparability studies to demonstrate that the change does not impact the product’s quality, safety, or efficacy. |

Academic

From a clinical and biochemical perspective, the therapeutic potential of peptides is rooted in their high specificity and potency, allowing them to modulate physiological pathways with a precision that small molecules often cannot match. This precision, however, is a double-edged sword.

The very biological complexity that makes peptides such powerful therapeutic agents also introduces significant manufacturing and regulatory challenges. The pathway to regulatory approval is a rigorous, multi-stage process that is fundamentally shaped by the physicochemical nature of the peptide itself.

For those of us who work with these molecules, understanding the interplay between manufacturing intricacies and regulatory expectations is essential. The timeline to approval is a direct function of a manufacturer’s ability to provide a comprehensive and convincing data package that addresses every aspect of the peptide’s Chemistry, Manufacturing, and Controls (CMC). This is a process where even the smallest details can have profound implications for the safety and efficacy of the final product.

The Molecular Scrutiny of Peptide Synthesis

The predominant method for producing synthetic peptides, solid-phase peptide synthesis (SPPS), is a marvel of chemical engineering. However, it is an inherently imperfect process. Each coupling step, where a new amino acid is added to the growing peptide chain, carries a small but finite risk of failure.

Over the course of synthesizing a 30- or 40-amino-acid peptide, these small risks can accumulate, leading to a heterogeneous mixture of closely related impurities. These can include deletion sequences, where an amino acid is missing; insertion sequences, where an extra amino acid is incorporated; or chemically modified versions of the target peptide.

Regulatory bodies, such as the FDA and the European Medicines Agency (EMA), require an exhaustive characterization of these impurities. This involves the use of orthogonal analytical methods, such as reversed-phase high-performance liquid chromatography (RP-HPLC) coupled with high-resolution mass spectrometry (HRMS), to identify and quantify each impurity.

The manufacturer must then establish a “specification,” which is a set of acceptance criteria for the purity and impurity profile of the drug substance. Any batch that falls outside of these specifications cannot be released. The process of developing and validating these highly sensitive analytical methods and establishing a scientifically justified specification is a major undertaking that significantly influences the regulatory timeline.

The path to peptide approval is paved with meticulous analytical data, where every peak on a chromatogram tells a story that regulators must fully understand.

What Is the Impact of Impurities on Immunogenicity?

A primary concern for regulators when evaluating a peptide therapeutic is its potential to elicit an immune response. The immunogenicity of a peptide is influenced by a multitude of factors, including its amino acid sequence, its route of administration, and the patient’s own immune system.

However, impurities introduced during the manufacturing process are a critical and highly scrutinized factor. A single amino acid substitution or deletion can create a new T-cell epitope, which is a short peptide sequence that can be presented by major histocompatibility complex (MHC) molecules on the surface of antigen-presenting cells.

If this new epitope is recognized by T-cells, it can trigger an adaptive immune response, leading to the formation of anti-drug antibodies (ADAs). These ADAs can have a range of clinical consequences, from neutralizing the therapeutic effect of the peptide to, in rare instances, causing severe hypersensitivity reactions.

Consequently, regulatory agencies require a thorough immunogenicity risk assessment for any new peptide therapeutic. This often involves a combination of in silico tools to predict T-cell epitopes, in vitro assays to measure T-cell activation, and careful monitoring of ADA formation in clinical trials. If a manufacturing change introduces a new impurity, its immunogenic potential must be rigorously assessed, often leading to significant delays in the regulatory process.

- Process-Related Impurities ∞ These are impurities that arise from the manufacturing process itself, such as residual solvents, reagents, or catalysts. While often easier to remove than peptide-related impurities, they must still be carefully controlled and monitored.

- Peptide-Related Impurities ∞ These are the most challenging impurities to deal with, as they are structurally very similar to the target peptide. They include deletion sequences, insertion sequences, and chemically modified peptides. Their potential to impact both the efficacy and the safety of the drug is a major focus of regulatory review.

- Aggregation ∞ Peptides have a tendency to self-associate and form aggregates. These aggregates can be more immunogenic than the monomeric peptide and can also impact the drug’s solubility and stability. Controlling and monitoring aggregation is a critical aspect of peptide manufacturing and a key regulatory expectation.

| Phase of Development | Focus of Regulatory Scrutiny | Required Data |

|---|---|---|

| Early Phase (Phase I) | Safety and initial characterization. | Preliminary impurity profile, identification of major impurities, and initial stability data. |

| Mid Phase (Phase II) | Process consistency and dose-ranging. | More complete impurity profile, justification for specifications, and more extensive stability data. |

| Late Phase (Phase III) | Process validation and comprehensive characterization. | Fully validated analytical methods, complete impurity profile with identified and qualified impurities, and long-term stability data from multiple batches. |

| Post-Approval | Maintaining consistency and managing changes. | Ongoing stability monitoring and comparability studies for any process changes. |

References

- De Groot, A. S. & Roberts, B. J. (2023). Immunogenicity risk assessment of synthetic peptide drugs and their impurities. Drug Discovery Today, 28(10), 103714.

- Food and Drug Administration. (2019). Impact Story ∞ Developing the Tools to Evaluate Complex Drug Products ∞ Peptides. FDA.

- Food and Drug Administration. (2021). Non-clinical Immunogenicity Assessment of Generic Peptide Products ∞ Development, Validation, and Sampling. FDA.

- Staby, A. et al. (2019). Regulatory Considerations for Peptide Therapeutics. In Peptide Therapeutics (pp. 1-30). Royal Society of Chemistry.

- Srivastava, V. (Ed.). (2019). Peptide Therapeutics ∞ Strategy and Tactics for Chemistry, Manufacturing, and Controls. Royal Society of Chemistry.

- IPQ. (2024). FDA’s Katharine Duncan on CMC Expectations for Therapeutic Peptides. IPQ.

- DLRC Group. (2023). Synthetic Peptides ∞ Understanding The New CMC Guidelines. DLRC Group.

- BioPharm International. (2010). Quality Considerations for Peptide Manufacturing Processes. BioPharm International.

Reflection

Understanding the immense scientific and regulatory rigor behind every therapeutic peptide brings a new perspective to your own health journey. The complexities that define the approval process are a direct reflection of the intricate biological systems these molecules are designed to support.

This knowledge transforms you from a passive recipient of care into an informed partner in your own wellness. It empowers you to ask deeper questions, to appreciate the precision of your protocols, and to recognize that the path to reclaiming your vitality is a collaborative one.

The science is the foundation, but your personal experience, your symptoms, and your goals are what give it meaning. As you move forward, consider how this deeper understanding of the ‘why’ behind your therapies can shape the ‘how’ of your personal health strategy.

Glossary

therapeutic peptides

food and drug administration

fda

amino acids

solid-phase peptide synthesis

spps

immune response

regulatory approval

cmc

peptide synthesis

regulatory agencies require

analytical methods

impurity profile

immunogenicity

thorough immunogenicity risk assessment

immunogenicity risk assessment