Fundamentals

Your journey toward hormonal balance is a deeply personal one, a process of listening to your body and seeking a state of optimal function. You feel the subtle shifts in energy, mood, and vitality that signal a need for recalibration.

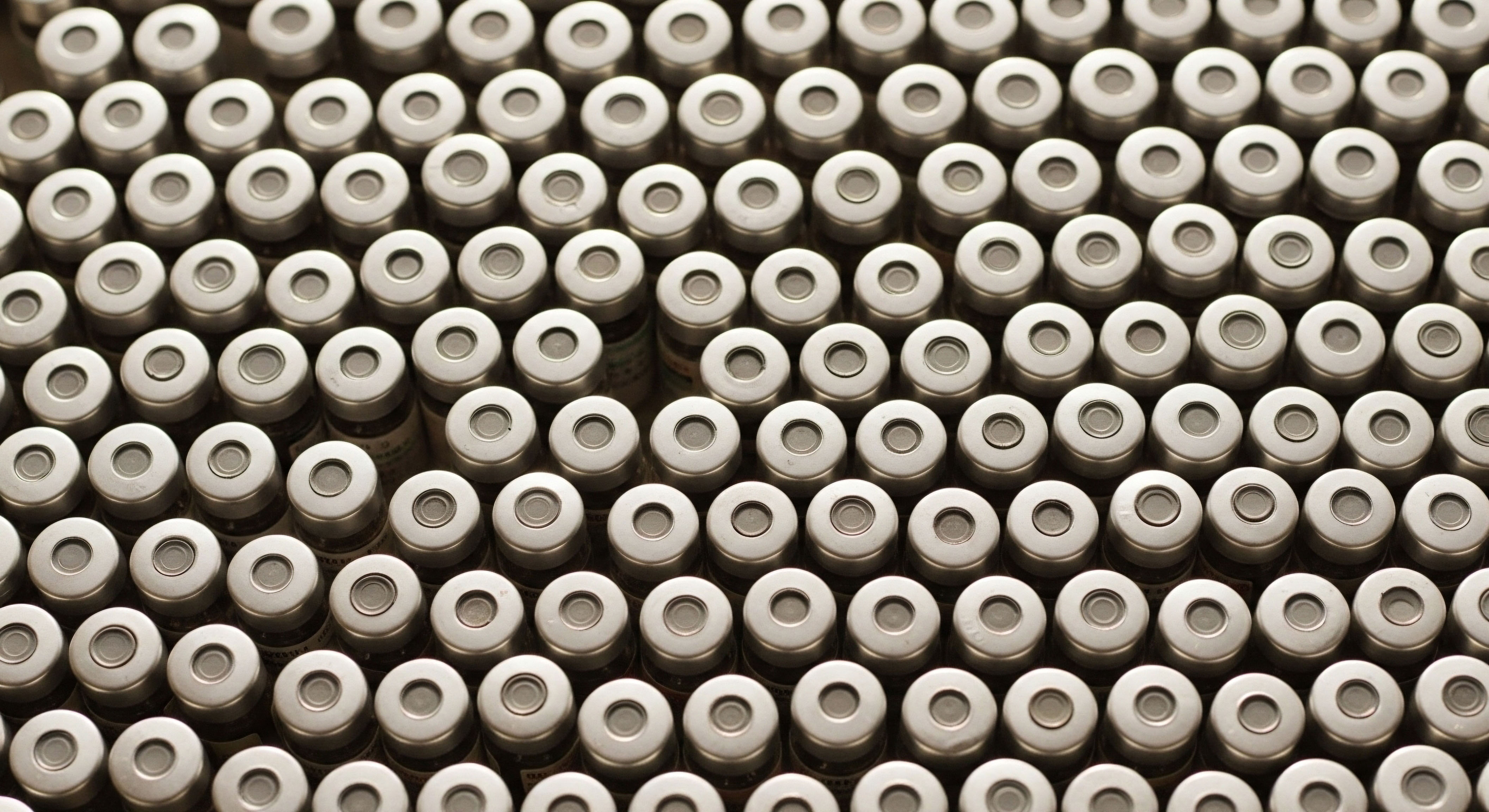

When you begin a personalized wellness protocol, you place your trust in the science designed to restore your system’s equilibrium. At the very heart of that science, within every vial or capsule, lies the Active Pharmaceutical Ingredient, or API. This is the specific molecule, the biological messenger, that interacts with your cells to produce a desired physiological effect.

Think of it as the essential, defining component in a complex formulation. The Testosterone Cypionate Meaning ∞ Testosterone Cypionate is a synthetic ester of the androgenic hormone testosterone, designed for intramuscular administration, providing a prolonged release profile within the physiological system. that forms the basis of your endocrine support, the Anastrozole that helps maintain metabolic balance, or the Ipamorelin peptide that signals your pituitary are all APIs.

The quality of this core ingredient is paramount. Its purity, consistency, and structural integrity directly determine the effectiveness and safety of your therapy. Your ability to achieve stable, predictable results ∞ the feeling of well-being you seek ∞ originates with the quality of the API molecule itself.

This is where the world of global regulation enters your personal health story. Major international bodies, primarily the United States Food and Drug Administration Meaning ∞ The Food and Drug Administration (FDA) is a U.S. (FDA) and the European Medicines Agency (EMA), act as gatekeepers of quality. They establish the rules, known as Good Manufacturing Practices (GMP), that govern how these sensitive molecules are produced.

These agencies are the architects of the quality control systems that oversee the journey of an API from its synthesis in a laboratory to its inclusion in your therapeutic protocol.

The consistency of your personal hormone therapy begins with the verifiable quality of its core active ingredient.

These regulatory bodies share a common objective ∞ ensuring the safety and efficacy of medicines. They both demand rigorous standards. Yet, they operate with different philosophies and procedural expectations. The FDA’s regulations, found in the Code of Federal Regulations (CFR), tend to be prescriptive, providing detailed and specific rules that manufacturers must follow.

The EMA, through its EudraLex guidelines, often operates on a more principle-based approach, outlining core objectives for quality and risk management Meaning ∞ Risk Management is the systematic process of identifying, assessing, and mitigating potential adverse events or uncertainties impacting patient health outcomes or treatment efficacy. and expecting manufacturers to design and justify their own robust systems to meet those goals. These subtle yet significant differences in regulatory style create a complex global landscape for sourcing APIs.

A manufacturer in one part of the world might operate under a system that is perfectly compliant with one agency’s rules but requires adaptation to meet the expectations of another. This variance has direct implications for the availability, cost, and even the consistency of the APIs used in your wellness program. Understanding this framework is the first step in appreciating the invisible forces that shape your therapeutic outcomes.

Intermediate

As you progress in your understanding of hormonal health, you begin to appreciate the fine details that influence your body’s response to therapy. The concept of an Active Pharmaceutical Ingredient Meaning ∞ The Active Pharmaceutical Ingredient, often abbreviated as API, refers to the biologically active component within a drug product responsible for its intended therapeutic effect. (API) evolves from a simple definition to a recognition of its central role in your protocol’s success.

The regulatory discrepancies between global authorities like the FDA and EMA Meaning ∞ EMA, in the context of hormonal health, refers to Estrogen Metabolism Assessment, a detailed evaluation of how the body processes and eliminates estrogen hormones. are not abstract bureaucratic details; they are practical factors that directly influence the quality and consistency of the APIs available for compounding your specific formulations. These differences are most evident in the application of Good Manufacturing Practices Meaning ∞ Good Manufacturing Practices (GMP) represent a regulatory framework and a set of operational guidelines ensuring pharmaceutical products, medical devices, food, and dietary supplements are consistently produced and controlled according to established quality standards. (GMP), the comprehensive set of standards that ensures APIs are produced and controlled to meet quality specifications.

Philosophical Divides in Regulation

The core distinction in regulatory approach shapes the entire manufacturing and sourcing process. The FDA’s system is largely prescriptive, meaning its regulations (specifically 21 CFR Parts 210 and 211) provide explicit instructions on what must be done. This creates a clear checklist for compliance. The EMA’s framework, outlined in EudraLex Volume 4, is founded on principles of Quality Risk Management Meaning ∞ Quality Risk Management represents a systematic process for the identification, assessment, control, communication, and review of risks to the quality of a product or service throughout its entire lifecycle. (QRM).

It sets forth foundational goals for product quality and patient safety and requires manufacturers to use risk assessment tools to design and validate processes that achieve these goals. For a patient, this means an API sourced from an EMA-regulated facility has been produced under a system that emphasizes proactive risk mitigation, while an API from an FDA-regulated facility has met a series of detailed, mandated requirements.

The Role of the Qualified Person

A significant structural difference is the EMA’s requirement of a Qualified Person Meaning ∞ A Qualified Person (QP) is an individual with specific professional qualifications and experience, legally responsible for certifying that each batch of a medicinal product, such as hormones or peptides, has been manufactured and checked according to its marketing authorization and Good Manufacturing Practice (GMP) regulations. (QP). The QP is a designated expert, typically a pharmacist or industrial chemist, who is personally responsible for certifying that each batch of an API or finished drug product has been manufactured in accordance with EU GMP and the relevant marketing authorization.

This introduces a layer of individual, professional accountability that has no direct equivalent in the FDA Meaning ∞ The Food and Drug Administration, or FDA, is a federal agency within the U.S. system. The QP must personally sign off on a batch before it can be released to the market, attesting to its full compliance. This can provide an additional level of assurance regarding the quality and consistency of APIs sourced from the European Union.

How Do Sourcing and Quality Control Differ?

These regulatory differences manifest in tangible ways during the sourcing and manufacturing of APIs like Testosterone Cypionate or Anastrozole. A compounding pharmacy or pharmaceutical company must navigate these variances when qualifying a supplier.

- Supplier Audits ∞ When qualifying a new API supplier, a company must audit the manufacturing facility. An audit focused on FDA compliance will verify adherence to the specific rules in the CFR. An audit for EMA compliance will assess the robustness of the facility’s Quality Risk Management system and its supporting documentation.

- Documentation Practices ∞ The FDA requires meticulous and accessible records that demonstrate compliance with its prescribed rules. The EMA’s principle-based system often requires more extensive justification documents, where the manufacturer explains the rationale behind its process design and control strategy based on risk assessments.

- Inspection Methodologies ∞ FDA inspections can be unannounced and are often intensely focused on adherence to the written regulations. EMA inspections, often conducted by national authorities within the EU, may place greater emphasis on the overall effectiveness of the quality system and the manufacturer’s understanding of its own processes.

| Regulatory Aspect | FDA (United States) | EMA (European Union) |

|---|---|---|

| Governing Philosophy | Prescriptive and rule-based, as detailed in 21 CFR 210/211. | Principle-based with an emphasis on Quality Risk Management (QRM), as per EudraLex Volume 4. |

| Key Requirement | Strict adherence to specified protocols and procedures. | Implementation of a robust Pharmaceutical Quality System (PQS) justified by risk assessment. |

| Batch Release | Responsibility lies with the manufacturer’s quality unit. | Requires personal certification by a named Qualified Person (QP) for each batch. |

| Documentation Style | Focus on detailed records proving adherence to established rules. | Focus on documentation that justifies process controls based on scientific and risk-based principles. |

| Inspection Focus | Compliance with specific, codified regulations. | Effectiveness of the overall quality system and risk management integration. |

For your personalized therapy, these distinctions are meaningful. An API sourced from a supplier adept at navigating both systems is likely to have undergone more comprehensive quality scrutiny. The choice of where to source an API is a complex decision involving cost, logistics, and a deep understanding of these overlapping yet distinct regulatory worlds.

Ultimately, the goal is to secure a consistent supply of high-purity API to ensure that the dose you administer behaves in your body predictably and effectively every single time.

Academic

The conversation about Active Pharmaceutical Ingredient (API) sourcing transcends logistical and economic considerations, entering the realm of clinical biochemistry and pharmacokinetics. For a patient undergoing hormonal optimization, the molecular integrity of an API like Testosterone Cypionate is not an abstract variable.

It is the primary determinant of the therapy’s pharmacokinetic profile, which in turn governs the physiological response and the patient’s subjective sense of well-being. Global regulatory discrepancies can permit subtle but clinically significant variations in API manufacturing, which can manifest as differences in purity, polymorphic form, or particle size distribution. These variations can directly alter how the molecule is absorbed, distributed, metabolized, and excreted, a cascade of events that defines the therapeutic experience.

Pharmacokinetic Impact of API Variability

Testosterone Cypionate is a prodrug; it is an esterified form of testosterone that becomes biologically active only after the cypionate ester is cleaved off by enzymes in the body. The rate of this cleavage and the subsequent release of free testosterone into circulation are heavily dependent on the formulation’s characteristics, which begin with the API itself.

Intramuscular injection of Testosterone Cypionate creates a depot in the muscle tissue, from which the drug is slowly released. A study of its pharmacokinetics Meaning ∞ Pharmacokinetics is the scientific discipline dedicated to understanding how the body handles a medication from the moment of its administration until its complete elimination. reveals that a 200 mg injection can cause serum testosterone to rise to supraphysiologic levels (a Cmax around 1112 ng/dL) within 4-5 days, before declining over a two-week period. This peak-and-trough cycle is a known characteristic of the therapy.

Now, consider the introduction of API variability. A manufacturer operating under less stringent GMP might produce an API with a slightly different particle size distribution. Smaller particles could lead to faster dissolution in the oil vehicle and more rapid absorption from the muscle depot.

This could result in a higher, faster Cmax and a shorter duration of action, steepening the peak-and-trough curve. For the patient, this might manifest as heightened mood fluctuations or a feeling that the effects wear off days earlier than expected.

Conversely, an API with larger or less uniform crystals could lead to slower, more erratic absorption, resulting in a blunted Cmax and unpredictable therapeutic levels. These are not failures of the molecule itself, but failures of manufacturing consistency, often rooted in the rigor of the overseeing regulatory framework.

Subtle variations in an active ingredient’s physical properties, permitted by regulatory gaps, can directly alter its behavior within your biological systems.

What Is the Consequence of API Impurities on Endocrine Function?

Beyond physical properties, the purity profile of an API is a critical factor governed by GMP. The synthesis of complex steroid hormones can result in residual solvents, starting materials, or structurally similar byproducts. Regulatory bodies like the FDA and EMA set strict limits on these impurities.

Discrepancies in enforcement or in the analytical methods required for detection can lead to APIs with different impurity profiles entering the supply chain. Some impurities might be biologically inert. Others could be endocrinologically active.

An impurity that is structurally similar to the parent API could potentially bind to androgen or estrogen receptors, either as an agonist or an antagonist, creating an unpredictable and confounding biological signal. This introduces a layer of “noise” into a therapeutic system designed for precision, potentially contributing to side effects or a diminished response to treatment.

| API Parameter Variation | Potential Pharmacokinetic Consequence | Clinical Manifestation for the Patient |

|---|---|---|

| Decreased Particle Size | Increased surface area leads to faster dissolution and absorption from the intramuscular depot. Results in a higher Cmax and shorter Tmax. | A more pronounced initial surge in effects, followed by a quicker decline. Potential for increased mood lability. |

| Polymorphic Differences | Different crystalline forms (polymorphs) of the same API can have different solubility and stability profiles. A less stable polymorph could degrade faster. | Inconsistent therapeutic effect from batch to batch. Reduced shelf-life of the compounded medication. |

| Presence of Active Impurities | Impurities may have their own pharmacokinetic and pharmacodynamic profiles, including receptor binding affinity. | Unexpected side effects (e.g. higher than expected aromatization) or a blunted therapeutic response. |

| Residual Solvents | Solvents used in crystallization may be present at low levels. Higher levels can increase local tissue irritation. | Increased post-injection pain or inflammation at the injection site. |

This level of analysis is particularly critical for more complex molecules like peptides. Peptides such as Sermorelin or CJC-1295 are larger and more fragile than small-molecule steroids. Their synthesis is more complex, and ensuring the correct amino acid sequence and three-dimensional folding is a significant manufacturing challenge.

The regulatory oversight for these biologics is even more stringent. Sourcing peptide APIs requires an exceptionally high degree of confidence in the manufacturer’s process controls and analytical capabilities, as even minute variations can render the product ineffective or immunogenic. The global discrepancies in the regulation of these advanced therapeutic agents represent a significant challenge in ensuring consistent and safe access for patients engaged in advanced wellness protocols.

- API Characterization ∞ A robust regulatory framework demands extensive characterization of the API, including its solid state form (polymorphism) and purity profile, using advanced analytical techniques like X-ray diffraction and High-Performance Liquid Chromatography (HPLC).

- Process Validation ∞ Manufacturers must prove that their production process consistently yields an API meeting all specifications. This validation is a cornerstone of both FDA and EMA GMP requirements, though the documentation philosophy may differ.

- Stability Testing ∞ Rigorous stability testing under various conditions is required to establish the API’s shelf-life and ensure it does not degrade into potentially harmful substances over time. This is a critical safety parameter checked by regulators.

References

- Nieschlag, E. & Behre, H. M. editors. Testosterone ∞ Action, Deficiency, Substitution. 4th ed. Cambridge University Press, 2012.

- Bassil, N. et al. “The Benefits and Risks of Testosterone Replacement Therapy ∞ A Review.” Therapeutics and Clinical Risk Management, vol. 5, 2009, pp. 427-48.

- “EudraLex – Volume 4 – Good Manufacturing Practice (GMP) guidelines.” European Commission, Public Health, 2022.

- “CFR – Code of Federal Regulations Title 21.” U.S. Food and Drug Administration, www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=211. Accessed 2 Aug. 2025.

- Behre, H. M. et al. “Comparative pharmacokinetics of testosterone enanthate and testosterone cypionate.” Clinical Endocrinology, vol. 49, no. 6, 1998, pp. 761-68.

- “Guideline on the chemistry of active substances.” European Medicines Agency, Committee for Medicinal Products for Human Use (CHMP), 2016.

- Yu, L.X. et al. “Understanding pharmaceutical quality by design.” The AAPS Journal, vol. 16, no. 4, 2014, pp. 771-83.

- “ICH Q7 Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.” International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use, 2016.

Reflection

You began this journey to understand your body on a more profound level, to move beyond managing symptoms and toward cultivating a state of genuine vitality. The knowledge that the quality of your therapy is influenced by a global network of regulations, manufacturing processes, and scientific principles adds a new dimension to that journey.

It transforms you from a passive recipient of care into an informed advocate for your own health. The dialogue with your clinician can now be enriched with a deeper appreciation for the consistency and source of the therapeutic agents you use. This understanding is a powerful tool.

It allows you to ask more precise questions and to partner with your provider in a shared pursuit of predictable, stable, and optimal outcomes. Your path to wellness is a collaborative one, built on a foundation of trust, communication, and now, a clearer insight into the very molecules that help restore your system’s design.