Fundamentals

You may be here because you feel a distinct shift within your own body. Perhaps it is a subtle decline in energy that sleep does not seem to fix, a frustrating plateau in your fitness goals, or a change in your mental clarity that leaves you feeling unlike yourself.

In seeking answers, you have likely encountered the world of peptide therapies and with it, the term “compounding.” This is the starting point for understanding how you can access these powerful tools and, most importantly, how you can ensure the path you choose is a safe one. Your journey to reclaiming your vitality is a deeply personal one, and it begins with understanding the systems that govern your own biology and the landscape of personalized medicine.

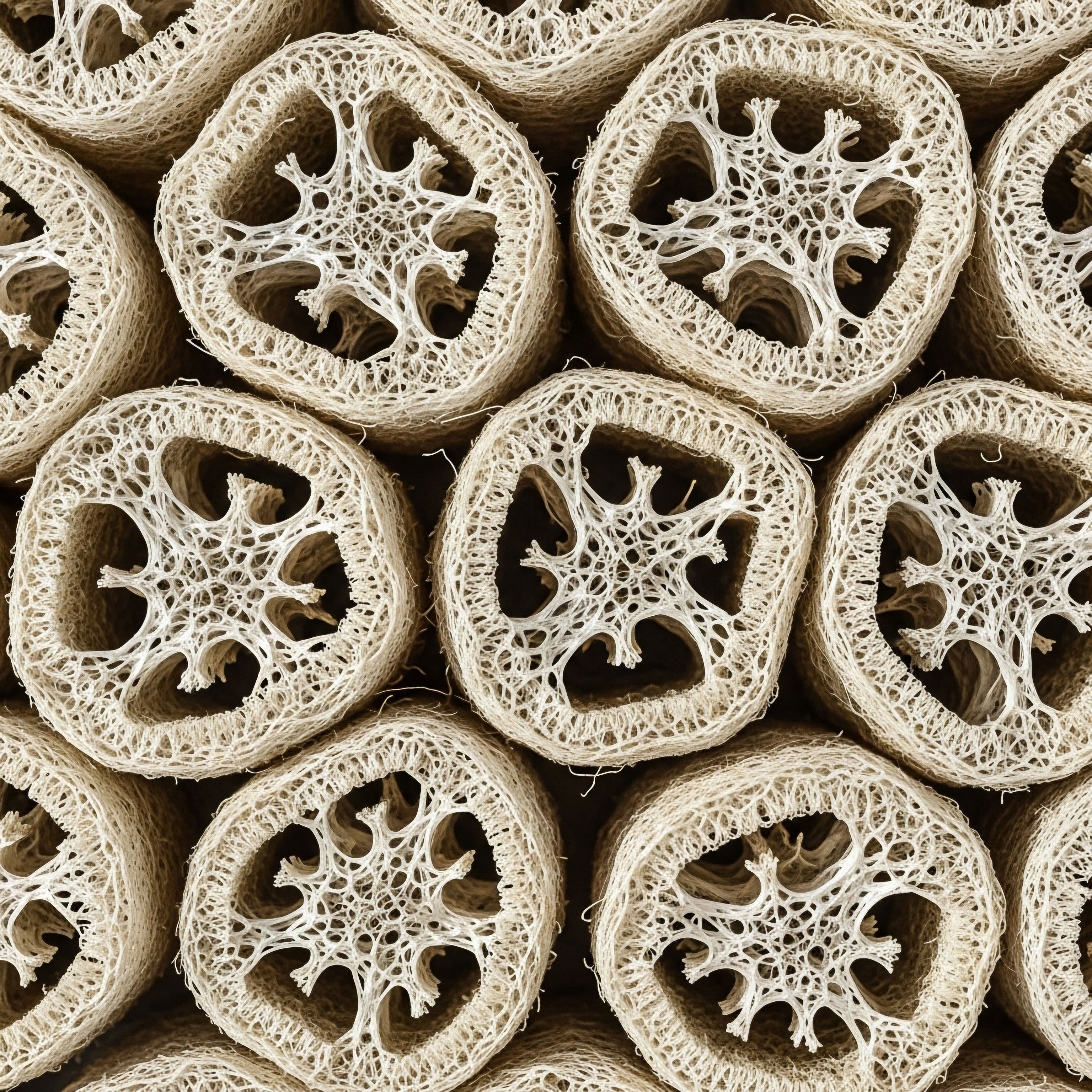

Compounding is the practice of creating a medication that is tailored to an individual patient. Think of it as the difference between buying a suit off the rack and having one custom-made by a skilled tailor. A commercial drug is the off-the-rack suit, designed for a broad population.

A compounded medication is tailored to your specific needs, whether that means a unique dosage, a different delivery method like a subcutaneous injection instead of a pill, or a formulation free of an allergen. This level of personalization is precisely why compounding is central to advanced wellness protocols, especially in the realm of peptide and hormone optimization.

The regulatory framework for compounded medications directly influences their availability and the quality assurances that protect patient health.

The Two Paths of Pharmaceutical Compounding

The U.S. Food and Drug Administration (FDA) recognizes two primary types of compounding facilities, and the distinction between them is foundational to understanding your access to therapies like Sermorelin or CJC-1295. These are not just administrative labels; they represent two different models of production, oversight, and scale that have direct implications for you as a patient. Understanding this structure empowers you to ask the right questions and make informed choices about where your medications originate.

503a Compounding Pharmacies the Local Apothecary Model

A 503A facility is what most people picture when they think of a traditional pharmacy that compounds. These are state-licensed pharmacies that prepare customized medications for specific patients based on a prescription from a licensed practitioner. Their work is done on a smaller scale, serving the needs of individuals in their community or region.

The defining characteristic of a 503A pharmacy is the requirement for a patient-specific prescription before a medication can be compounded. They operate under the standards set by the United States Pharmacopeia (USP), which provides detailed guidelines for compounding practices, particularly for sterile preparations.

- Patient-Specific ∞ A 503A pharmacy cannot mass-produce medications. Each preparation is tied directly to an individual’s prescription.

- State-Licensed ∞ Their primary oversight comes from state boards of pharmacy, which enforce both state regulations and USP standards.

- Smaller Scale ∞ They are designed to fill individual prescriptions, not to produce large batches for office use or for sale to other facilities.

503b Outsourcing Facilities the Quality-Controlled Production Model

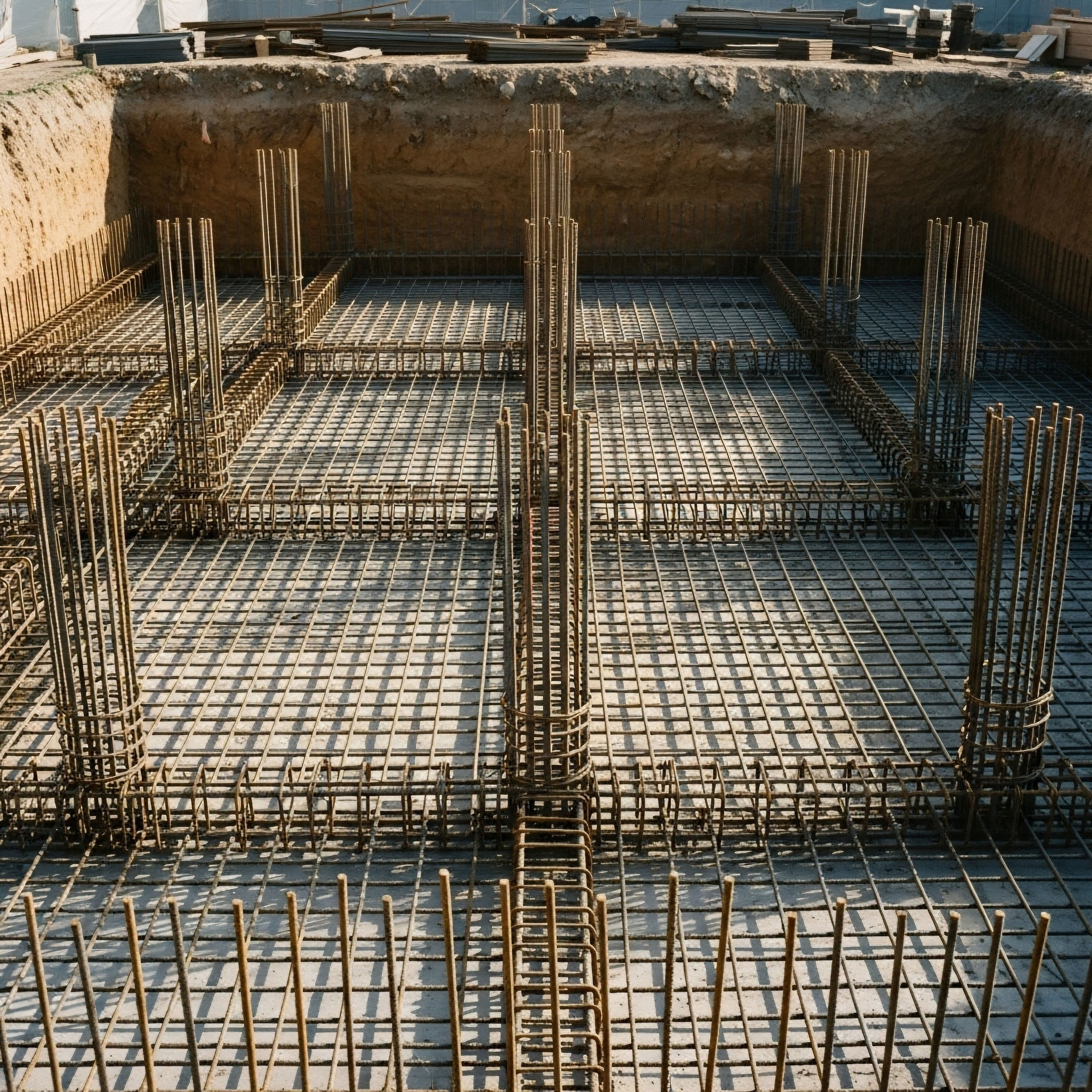

The concept of the 503B outsourcing facility was established to fill a critical gap, particularly for hospitals and clinics that need larger quantities of compounded sterile medications without patient-specific prescriptions. These facilities operate on a much larger scale.

A 503B facility must register with the FDA and adhere to Current Good Manufacturing Practices (cGMP), the same stringent quality standards that major pharmaceutical manufacturers follow. This higher level of regulation allows them to produce large batches of medications that can be sold to healthcare providers for office use. This means a clinic can keep a stock of a commonly used peptide injection from a 503B facility, ready for administration.

- FDA-Registered ∞ 503B facilities are directly registered with and inspected by the FDA.

- cGMP Standards ∞ They must follow the rigorous cGMP guidelines, which involve extensive quality control, testing, and process validation.

- Non-Patient-Specific ∞ They can compound medications in large batches without a prescription for a specific individual, allowing for office use by clinicians.

Your physician’s choice to source your peptide therapy from a 503A or a 503B facility is therefore a clinical decision rooted in these regulatory and operational differences. A 503B source provides a high degree of quality assurance due to cGMP standards, while a 503A source offers customized preparations based on your unique prescription. Both play a role in the ecosystem of personalized medicine, and understanding their functions is the first step in navigating your therapeutic options safely and effectively.

Intermediate

As you move from a basic awareness of compounding to a deeper appreciation of its role in your health protocol, the regulatory mechanics become increasingly relevant. The safety and accessibility of peptides are not arbitrary; they are the direct result of a structured, albeit complex, federal framework designed to balance patient access to necessary medications with the imperative of public safety.

This system determines which substances, including the very peptides used for metabolic health and tissue repair, can be legally compounded and under what conditions. For anyone on a journey of hormonal optimization, understanding this system is essential for evaluating the quality and legitimacy of a prescribed therapy.

The FDA’s classification of bulk drug substances is the central mechanism controlling which peptides are available through compounding pharmacies.

The FDA Bulks List a Gatekeeper for Compounded Therapies

At the heart of compounding regulation is the FDA’s list of bulk drug substances. A “bulk” substance is the raw, active pharmaceutical ingredient (API) that a pharmacist uses to compound a medication.

For a 503A pharmacy to use a bulk substance, it must generally meet one of three criteria ∞ it is part of an existing FDA-approved drug, it has a monograph in the U.S. Pharmacopeia (USP), or it appears on a specific FDA-approved list. Since many therapeutic peptides are not components of mass-produced FDA-approved drugs, their eligibility for compounding hinges on their status on the FDA’s “bulks list.”

The FDA evaluates nominated substances and places them into one of three categories, which directly dictates their use.

How Are Peptides Categorized by Regulators?

The categorization process is a critical regulatory function that directly impacts which therapeutic agents are available to you. The FDA’s Pharmacy Compounding Advisory Committee (PCAC) reviews data on nominated substances to make these determinations.

- Category 1 ∞ Approved for Use. Substances in this category have been reviewed and are permissible for use in compounding by 503A and 503B facilities, provided all other conditions are met. The FDA has determined that there is not a significant safety risk associated with their use in compounding. An example is GHK-Cu, which was placed in Category 1 for non-injectable uses.

- Category 2 ∞ Significant Safety Risks Identified. This is a critical category for the world of peptide therapy. When the FDA places a substance in Category 2, it is signaling that significant safety concerns have been identified. Compounding with these substances is effectively prohibited, and the FDA can take regulatory action against pharmacies that use them. Several peptides have been moved to this category, limiting their access through compounding channels.

- Category 3 ∞ Insufficient Evidence. These are substances for which the FDA has determined there is not enough data to perform a full evaluation. They cannot be used in compounding until more information becomes available.

This system explains why access to certain peptides can change over time. As the FDA reviews more substances, a peptide that was once readily available might be moved to Category 2, making it difficult or impossible for compounding pharmacies to source and prepare legally. This regulatory shift is a primary driver of how peptide access is managed in the United States.

Comparing 503a and 503b Facilities

The operational and regulatory distinctions between 503A and 503B facilities are substantial. Understanding these differences helps clarify why your clinician might choose one source over another and what quality assurances are associated with each. The following table provides a direct comparison of their key attributes.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Governing Standard | USP Chapters (e.g. <795>, <797>) | Current Good Manufacturing Practices (cGMP) |

| Primary Oversight | State Boards of Pharmacy | Food and Drug Administration (FDA) |

| Prescription Requirement | Requires a valid, patient-specific prescription | Can produce for office stock without patient-specific prescriptions |

| Production Scale | Small-scale, for individual patients | Large-scale batch production |

| Sterility & Potency Testing | Testing may be performed on batches, but not always required for every single preparation. Follows USP guidelines. | Rigorous testing for sterility, potency, and endotoxins is required for every batch released. |

| Use of Bulk Substances | Can use substances from the FDA’s Category 1 list, those with a USP monograph, or components of FDA-approved drugs. | Can only use substances from the FDA’s 503B bulks list (Category 1) or drugs currently in shortage. |

What Makes a Drug Difficult to Compound?

Beyond the bulks list, the FDA also has the authority to declare certain drugs or categories of drugs as “demonstrably difficult for compounding” (DDC). If a drug product is placed on this list, it cannot be compounded by either 503A or 503B facilities.

The criteria for this designation relate to the complexity of creating a safe and effective final product. This includes challenges with the formulation, delivery system, or the ability to ensure proper bioavailability. For example, complex formulations like liposomal drug products or modified-release coated tablets are proposed for this list because replicating them safely and effectively outside of a controlled manufacturing environment is exceedingly difficult.

While peptides are not currently on a DDC list, this regulatory tool represents another layer of control that could affect access in the future if certain peptide formulations are deemed too complex for compounding.

Academic

A sophisticated understanding of peptide access and safety requires a deep examination of the scientific principles that underpin sterile pharmaceutical preparation. From a clinical and biochemical perspective, the regulations governing compounding are a direct response to tangible, measurable risks.

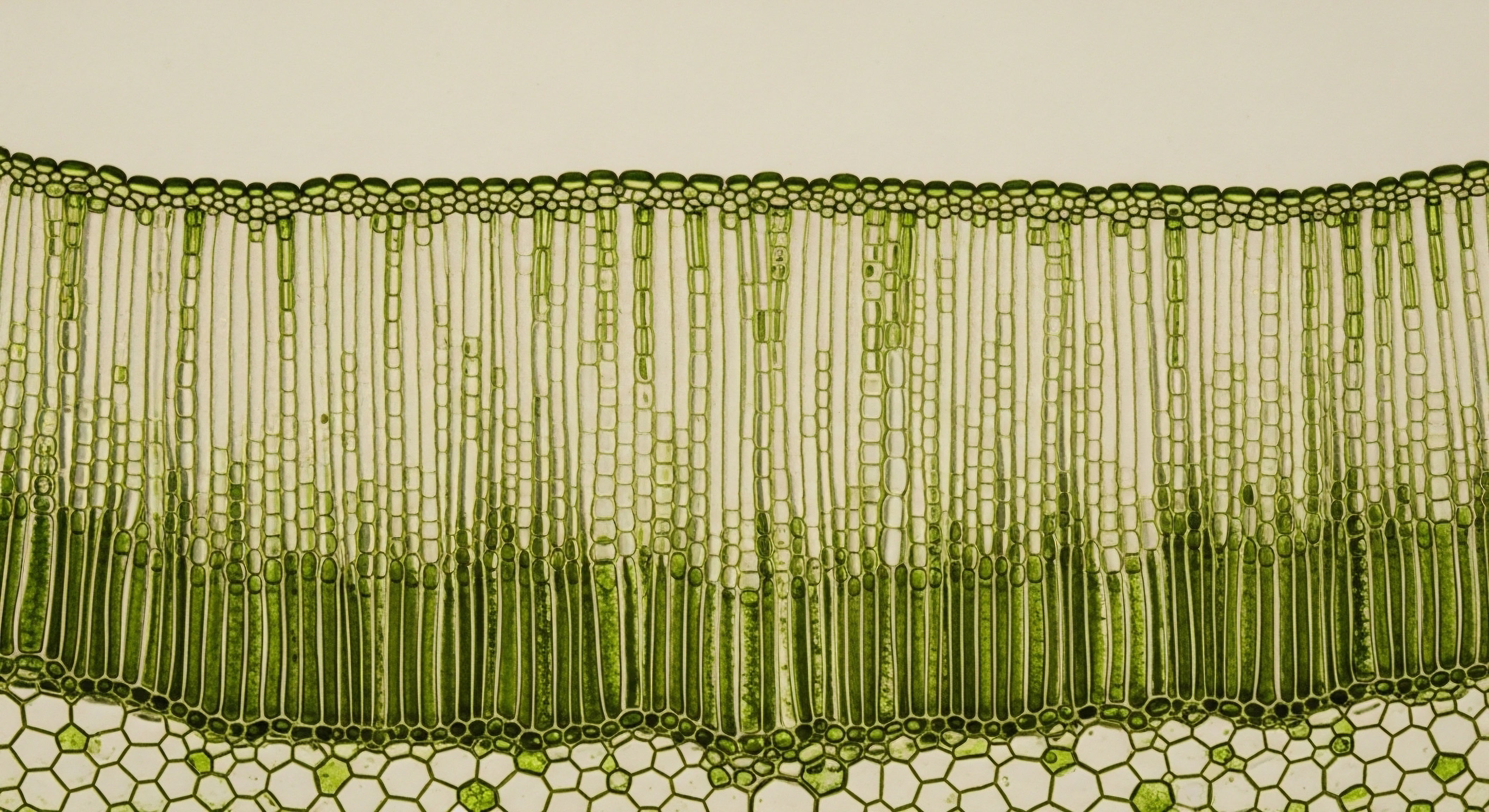

The distinction between a 503A and 503B facility transcends mere legal classification; it reflects a fundamental difference in the validated processes used to mitigate the risk of contamination and ensure the chemical integrity of the final product. For injectable therapies like peptides, which bypass the body’s primary physical and immunological barriers, the margin for error is exceptionally small. The discussion must therefore center on the science of sterility, pyrogenicity, and product integrity.

The Microbiological Imperative of USP Chapter 797

The foundational standard for sterile compounding in 503A pharmacies is USP General Chapter <797>. This chapter outlines the minimum practice and quality standards to prevent patient harm from non-sterility, excessive bacterial endotoxins, and variations in intended strength.

The chapter classifies compounded sterile preparations (CSPs) into risk levels (low, medium, and high) based on the complexity of the compounding process and the potential for microbial contamination. For example, compounding that involves simple aseptic transfer of sterile ingredients is considered low-risk, while using non-sterile ingredients that must be sterilized before administration is high-risk.

The core scientific principle of USP <797> is the control of the environment and personnel to minimize the introduction of contaminants into the final preparation. This involves the use of ISO Class 5 air quality environments, proper garbing and aseptic technique, and stringent cleaning protocols.

Even a sterile preparation can pose a significant health risk if it contains pyrogenic bacterial endotoxins.

Beyond Sterility the Threat of Bacterial Endotoxins

A common misconception is that sterility ∞ the absence of living microorganisms ∞ is the sole indicator of a safe injectable product. A preparation can be perfectly sterile yet dangerously pyrogenic. This is due to the presence of endotoxins, which are lipopolysaccharide (LPS) components of the outer membrane of Gram-negative bacteria.

These molecules are shed from bacteria even when the organisms are killed during sterilization. When injected into the bloodstream, endotoxins can trigger a potent inflammatory response, leading to fever, hypotension, and in severe cases, septic shock and death.

This is why Current Good Manufacturing Practices (cGMP), which 503B facilities must follow, mandate rigorous testing for bacterial endotoxins in every batch of sterile product intended for injection. The standard method is the Limulus Amebocyte Lysate (LAL) test, which uses an extract from horseshoe crab blood to detect the presence of LPS.

While 503A pharmacies following USP <797> are also required to consider endotoxin limits, the batch-level validation and release testing under cGMP provides a higher, more consistent level of assurance. The potential for endotoxin contamination is a primary safety concern that drives the more stringent regulatory requirements for large-scale producers.

Pharmacological Integrity and Safety Risks

The safety of a compounded peptide extends beyond its sterility and pyrogenicity. It involves the chemical identity, purity, and potency of the active pharmaceutical ingredient itself. The FDA’s decision to place certain peptides, like CJC-1295, on a list of substances with potential safety risks is based on these pharmacological considerations.

What Are the Hidden Risks in Compounded Peptides?

The chemical nature of peptides makes them susceptible to specific risks that must be controlled through rigorous manufacturing and quality testing processes. These risks are a key part of the FDA’s evaluation.

| Risk Factor | Description | Clinical Implication |

|---|---|---|

| Peptide-Related Impurities | Synthetic peptide production can result in impurities, such as deletion sequences or improperly folded molecules. These impurities may have unknown biological activity or could be immunogenic. | The presence of impurities can reduce the efficacy of the intended therapy and may trigger adverse immune reactions, diminishing the safety profile of the product. |

| Immunogenicity | The body’s immune system may recognize a synthetic peptide, especially one with modifications or impurities, as a foreign substance. This can lead to the production of antibodies against the peptide. | Antibody formation can neutralize the therapeutic effect of the peptide. In some cases, it could even lead to autoimmune cross-reactivity with the body’s own endogenous hormones, a serious safety concern. |

| API Characterization & Stability | Ensuring the correct identity, strength, and purity of the bulk peptide substance is a complex analytical task. Peptides can degrade if not stored and handled under precise conditions. | Without proper characterization and stability testing, a patient may receive a sub-potent dose, an incorrect substance, or a degraded product with potentially harmful byproducts. |

| Lack of Clinical Data | Many compounded peptides have not undergone the extensive, large-scale clinical trials required for FDA-approved drugs. Their safety and efficacy profiles are often based on smaller studies or anecdotal evidence. | Adverse events may be underreported or unknown. The FDA has noted serious adverse events associated with some peptides, including systemic vasodilatory reactions. |

The regulatory framework, therefore, serves as a proxy for this deep scientific validation. The cGMP standards required of 503B facilities are designed to control for these exact pharmacological variables through process validation, raw material testing, and finished product analysis. The FDA’s categorization of bulk substances reflects a risk assessment based on these scientific principles.

When a peptide is moved to Category 2, it is often because the available evidence on its safety, purity, and potential for adverse reactions has raised significant concerns that outweigh the evidence for its therapeutic use in a less-controlled compounding environment.

References

- Food and Drug Administration. “Certain Bulk Drug Substances for Use in Compounding that May Present Significant Safety Risks.” FDA.gov, 2023.

- Kastango, Eric S. and Douglas J. Scheckelhoff. “The evolving landscape of sterile compounding.” American Journal of Health-System Pharmacy, vol. 80, no. 15, 2023, pp. 986-988.

- Food and Drug Administration. “Guidance for Industry ∞ Insanitary Conditions at Compounding Facilities.” FDA.gov, 2020.

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF), 2022.

- McDermott Will & Emery. “FDA Publishes Proposed Rule on 503A and 503B Compounding.” JDSupra, 2024.

- Hopple, Sherri. “Compounding Pharmacies and Bacterial Endotoxin Testing.” Charles River Laboratories, 2023.

- Allen, Loyd V. “To Compound or Not to Compound.” International Journal of Pharmaceutical Compounding, vol. 17, no. 5, 2013, pp. 358.

- Tsae, Ryan, and Kevin N. Nguyen. “Current Regulatory and Quality Standards for Compounded Preparations in the USA.” Journal of Pharmaceutical Policy and Practice, vol. 12, no. 1, 2019, p. 29.

Reflection

Charting Your Own Course with Knowledge

You began this exploration seeking to understand the intersection of regulations, peptides, and your personal health. The knowledge you now possess about the structure of compounding, the specific mechanisms of oversight, and the scientific basis for safety concerns is more than just information.

It is the critical toolset you need to engage with your health journey on a completely different level. The path to sustained vitality and optimal function is built upon informed, deliberate choices. This understanding allows you to move forward, not with uncertainty, but with the clarity to ask discerning questions.

Consider the source of your therapies. Think about the quality assurances that are most meaningful to you. This knowledge empowers you to have a substantive conversation with your clinician, transforming your role from a passive recipient of care to an active partner in your own wellness protocol.

Your biology is unique, and your path to optimizing it will be as well. Let this understanding be the foundation upon which you build a resilient, functional, and vibrant future, one well-informed decision at a time.

Glossary

personalized medicine

food and drug administration

sermorelin

503b outsourcing facility

current good manufacturing practices

quality standards

503b facilities

cgmp

503b facility

hormonal optimization

active pharmaceutical ingredient

bulk drug substances

compounding pharmacies

bacterial endotoxins

sterile compounding

good manufacturing practices