Fundamentals

Your journey toward hormonal optimization involves a deep trust in the medications designed for your specific physiology. When you receive a preparation, such as Testosterone Cypionate or a specialized peptide like Ipamorelin, its purity is paramount. The protocols that ensure this purity are built upon a foundational principle of patient safety.

Compounding pharmacy standards exist to prevent contamination, which is the introduction of harmful substances into these sterile medications. These standards are a protective barrier between you and unseen threats like microbes or bacterial toxins that could disrupt your body’s delicate endocrine balance and overall health.

The experience of hormonal imbalance, whether it manifests as fatigue, metabolic shifts, or changes in mood, is a deeply personal and often challenging one. The solutions, therefore, must be handled with an equivalent level of personal care and scientific precision.

The standards governing compounding pharmacies are designed to ensure that the customized hormonal therapies you rely on are free from any contaminants that could introduce new health challenges. These detailed procedures address every step of the process, from how the raw ingredients are handled to the environment in which they are combined, creating a system where the final product is a pure, safe, and effective tool for your wellness.

Compounding standards transform a pharmacy into a controlled environment where the safety and purity of your personalized medication are the highest priorities.

Understanding the “why” behind these rigorous protocols begins with appreciating the vulnerability of sterile medications. Unlike a tablet taken orally, which passes through the digestive system’s natural defenses, injectable therapies like TRT or growth hormone peptides enter directly into your muscle tissue or bloodstream.

This direct route of administration means there is no biological filter to catch potential contaminants. A microscopic error at the compounding stage could introduce bacteria or their byproducts, known as endotoxins, directly into your system. This is why the United States Pharmacopeia (USP) developed Chapter 797, a comprehensive set of rules that all sterile compounding facilities must follow to protect patients.

These guidelines are a clinical blueprint for safety. They dictate the specific air quality required in the compounding area, the meticulous personal hygiene and garbing procedures for technicians, and the constant, documented cleaning of all surfaces and equipment. Each rule is a direct response to a known risk.

By adhering to this framework, compounding pharmacies create an environment where the integrity of your personalized therapy is protected, allowing you to focus on the positive biological effects of your treatment without concern for its purity.

Intermediate

The effectiveness of hormonal and metabolic therapies depends entirely on the sterility and accuracy of the compounded preparations. To achieve this, compounding pharmacies operate under the stringent guidelines of USP Chapter 797, which provides a detailed operational framework for preventing contamination. This framework is built upon several core pillars that address the primary vectors of contamination ∞ personnel, the environment, and the process itself. Each element is meticulously controlled to ensure the final sterile product is safe for administration.

Aseptic Technique and Personnel Garbing

The most significant variable in a sterile environment is the human operator. Aseptic technique is the collection of practices designed to minimize the introduction of microbes from personnel into the sterile field. Before entering the cleanroom, technicians must follow a strict garbing procedure, which involves donning specific protective equipment in a precise order to minimize exposure. This process creates a physical barrier between the individual and the sterile compounding environment.

- Shoe Covers and Hair Nets ∞ These are the first items donned to contain contaminants from the floor and hair.

- Face Masks ∞ A mask is essential to prevent the shedding of microorganisms from the mouth and nose.

- Hand and Arm Washing ∞ Technicians perform a thorough hand and forearm washing, often for a specific duration, to reduce microbial bioburden on the skin.

- Gowns ∞ Non-shedding gowns provide a barrier for the torso and arms.

- Sterile Gloves ∞ Applied last, sterile gloves are critical for directly handling sterile components. Gloved fingertip sampling is performed regularly to test the technician’s ability to don gloves without contaminating them.

Engineering Controls and Environmental Monitoring

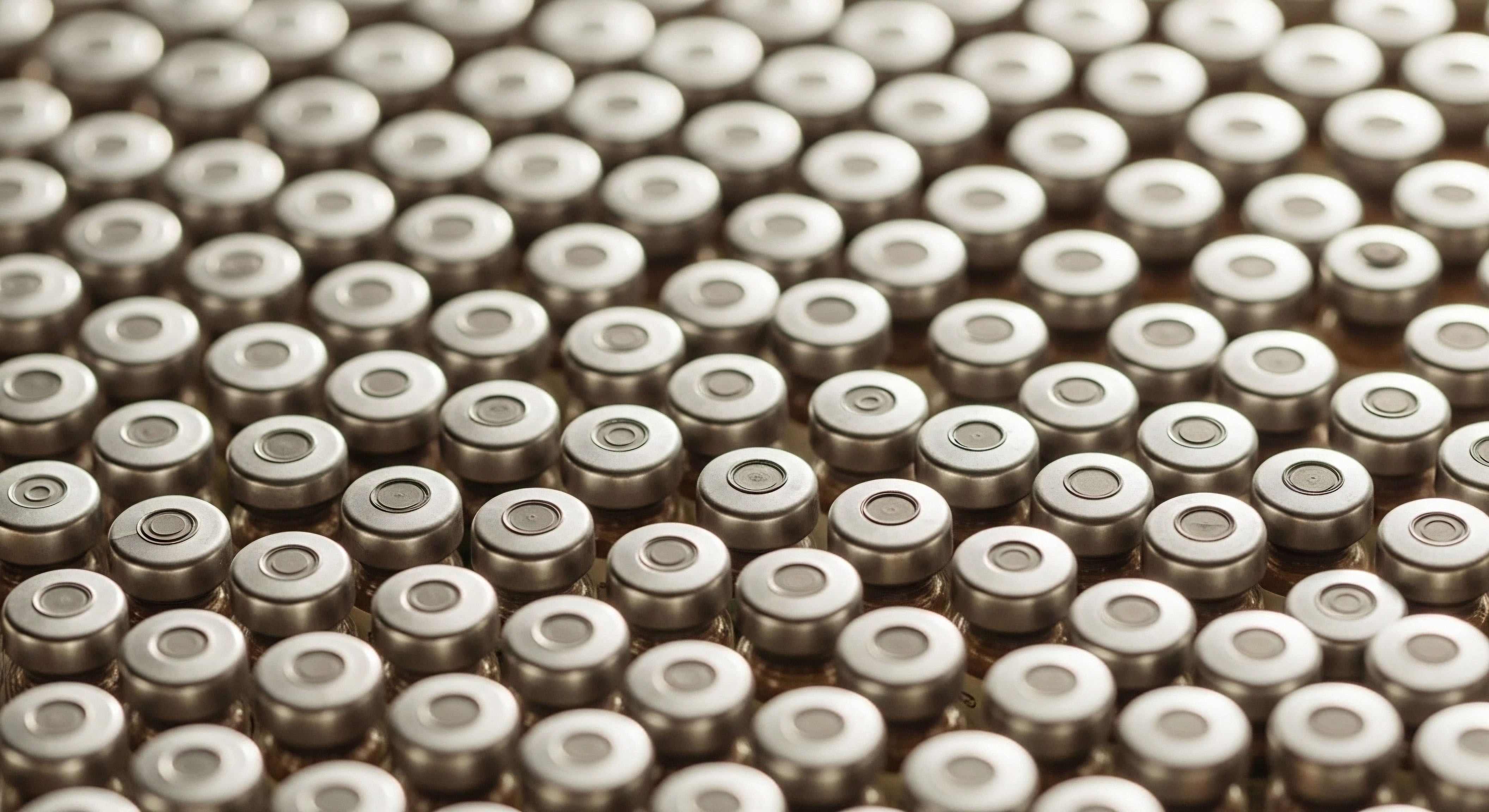

How does a pharmacy maintain a sterile space? The answer lies in sophisticated environmental controls that create a cleanroom, a space with a controlled level of airborne particulates. These controls are organized into a system of primary and secondary engineering controls.

The Primary Engineering Control (PEC) is the sterile hood or isolator where the actual compounding takes place. This device provides an ISO Class 5 environment, which means the air contains a very low number of particles, through the use of HEPA filters. The Secondary Engineering Control (SEC) is the buffer room that houses the PEC.

This room is maintained at a higher air pressure than adjacent areas to prevent contaminated air from entering. The entire environment is subject to continuous monitoring for airborne particles, temperature, and humidity, as well as routine surface sampling to detect any microbial growth.

A compounding pharmacy’s cleanroom functions as a highly controlled ecosystem where air quality, surfaces, and personnel are all managed to prevent microbial contamination.

Understanding Compounded Sterile Preparation Risk Levels

USP 797 categorizes compounded sterile preparations (CSPs) into different risk levels based on the probability of introducing contamination. This classification dictates the specific procedures and beyond-use dates (BUDs) for each preparation. The complexity of the compounding process and the sterility of the starting ingredients are key factors in this determination.

| Risk Level Category | Description of Process | Typical Starting Components | Potential for Microbial Growth |

|---|---|---|---|

| Category 1 | Compounding involves simple transfers using only sterile ingredients and equipment. The process is not complex. | Sterile commercial drugs, sterile diluents. | Low |

| Category 2 | Compounding involves more complex manipulations, such as combining multiple sterile products or a lengthy aseptic process. | Multiple sterile ingredients, multiple transfers. | Medium |

| Category 3 | Compounding involves using non-sterile ingredients or equipment at some stage, requiring a terminal sterilization step. | Non-sterile bulk drug substances, non-sterile equipment. | High |

For patients receiving therapies like TRT or peptide injections, the preparations are typically compounded as Category 1 or 2 CSPs. The distinction is important because it determines the BUD, which is the timeframe within which the medication must be used before the potential for microbial growth becomes a concern. Adherence to these risk-level classifications is a fundamental component of ensuring that the medication you receive is both safe and effective throughout its intended use period.

Academic

Beyond the physical containment of microbes, the most sophisticated challenge in sterile compounding is the management of pyrogenic substances, specifically bacterial endotoxins. Endotoxins are lipopolysaccharides (LPS) derived from the outer membrane of Gram-negative bacteria. They are released when these bacteria die and lyse.

Even in the absence of live bacteria, the presence of endotoxins in a parenteral medication can trigger a powerful and dangerous inflammatory cascade in the human body, leading to symptoms ranging from fever to septic shock. Therefore, compounding pharmacy standards are designed not just to ensure sterility (the absence of living organisms) but also to control for pyrogens.

The Pathophysiology of Endotoxin-Mediated Inflammation

When an injectable therapy contaminated with endotoxins enters the bloodstream, the lipid A portion of the LPS molecule is recognized by the innate immune system. This interaction primarily occurs through Toll-like receptor 4 (TLR4) on the surface of monocytes and macrophages. This binding event initiates a signaling cascade that results in the massive release of pro-inflammatory cytokines, such as Tumor Necrosis Factor-alpha (TNF-α), Interleukin-1 (IL-1), and Interleukin-6 (IL-6).

This cytokine surge is responsible for the systemic effects of endotoxemia. IL-1 and TNF-α act on the hypothalamus to induce fever. These cytokines also increase vascular permeability and vasodilation, which can lead to a precipitous drop in blood pressure, a hallmark of septic shock.

For an individual on a wellness protocol, such a reaction would be a catastrophic iatrogenic event, directly caused by a failure in the compounding process. This potential for severe harm underscores the absolute necessity of the stringent controls outlined in USP 797.

The control of endotoxins is a critical, non-negotiable aspect of sterile compounding, as these invisible molecules can provoke a severe systemic inflammatory response.

What Are the Advanced Methods for Endotoxin Detection?

Because endotoxins are invisible and cannot be detected by simple visual inspection, compounding pharmacies must rely on sophisticated analytical methods to verify the purity of their products, especially those classified as high-risk. The choice of testing method is a critical quality assurance decision.

- Limulus Amebocyte Lysate (LAL) Test ∞ This has been the industry-standard method for decades. The test utilizes a lysate derived from the amebocytes of the horseshoe crab (Limulus polyphemus). In the presence of endotoxin, the lysate initiates a coagulation cascade that can be measured. There are several variations of the LAL test:

- Gel-Clot ∞ A qualitative test where the formation of a solid gel indicates the presence of endotoxin above a certain threshold.

- Turbidimetric ∞ A quantitative test that measures the increase in turbidity (cloudiness) as the coagulation reaction proceeds.

- Chromogenic ∞ A quantitative test where the reaction produces a colored product that can be measured spectrophotometrically.

- Monocyte Activation Test (MAT) ∞ This newer method represents a significant advance because it more closely mimics the human physiological response. The MAT uses human monocytic cells and measures their production of inflammatory cytokines (like IL-6) in response to a sample. Its key advantage is the ability to detect both endotoxin and non-endotoxin pyrogens, providing a more comprehensive safety profile of the compounded preparation.

Why Is Terminal Sterilization and Depyrogenation so Important?

For the highest-risk compounded sterile preparations (Category 3), which may involve non-sterile starting ingredients, the process must include a final step to eliminate both microbes and endotoxins. Standard autoclaving (steam sterilization) is effective at killing bacteria but does not destroy endotoxins.

Endotoxins are heat-stable and require much higher temperatures for inactivation, a process known as depyrogenation, which is typically achieved through dry heat sterilization. This dual requirement of sterilization and depyrogenation for high-risk CSPs illustrates the depth of the standards required to protect patients from all forms of contamination.

| Contaminant Type | Definition | Method of Elimination | Primary Health Risk |

|---|---|---|---|

| Microbial Contamination | The presence of living microorganisms like bacteria or fungi. | Sterilization (e.g. autoclaving, filtration). | Infection, Sepsis. |

| Bacterial Endotoxins | Pyrogenic lipopolysaccharides from the cell wall of Gram-negative bacteria. | Depyrogenation (e.g. dry heat), use of endotoxin-free materials. | Fever, Inflammation, Septic Shock. |

References

- United States Pharmacopeial Convention. <797> Pharmaceutical Compounding ∞ Sterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ United States Pharmacopeial Convention; 2022.

- KASTEN, M. J. (2012). The 2012 US fungal meningitis outbreak ∞ a preventable public health tragedy. Annals of internal medicine, 157 (11), 824-825.

- Gudeman, J. Jozwiakowski, M. Chollet, J. & Randell, M. (2013). Potential Risks of Pharmacy Compounding. Drugs in R&D, 13(1), 1 ∞ 8.

- Mullarkey, T. (2009). Pharmacy compounding of high-risk level products and patient safety. American Journal of Health-System Pharmacy, 66(18 Supplement 6), S4-S13.

- Galanos, C. & Freudenberg, M. A. (1993). Bacterial endotoxins ∞ biological properties and mechanisms of action. Mediators of inflammation, 2 (Suppl 1), S11 ∞ S16.

Reflection

You have now seen the intricate systems and rigorous science that underpin the safety of your personalized therapies. This knowledge of compounding standards, from the foundational need for a clean environment to the academic complexities of endotoxin detection, serves a singular purpose ∞ to build a foundation of trust.

It demystifies the process, transforming the pharmacy from a simple dispensary into a highly specialized environment dedicated to the integrity of your treatment. Your path to wellness is a collaborative one, built on both your commitment to your health and the unwavering commitment of professionals to deliver safe, pure, and effective preparations. This understanding is the first, powerful step in taking active ownership of your biological journey.

Glossary

compounding pharmacies

sterile compounding

aseptic technique

cleanroom

primary engineering control

usp 797

monocyte activation test