Fundamentals

Your journey toward hormonal wellness begins with a deeply personal recognition. It is the quiet acknowledgment that the person you feel like on the inside is misaligned with your body’s current biological output. This experience, a subtle yet persistent sense of being out of sync, is the first step toward reclaiming your vitality. When you seek solutions, you enter a world of precise medical protocols, from testosterone replacement therapy (TRT) to targeted peptide use. The conversation inevitably turns to where these specific formulations originate. You may hear about standard pharmaceuticals and also about compounding pharmacies. Understanding the distinction between these two sources is fundamental to your path, as it directly relates to the safety, personalization, and efficacy of your treatment.

The decision to pursue a personalized hormonal protocol means you are seeking a level of customization that conventional medicine may not offer. Perhaps the commercially available dosage of a medication is too high or contains a filler you are allergic to. This is where the concept of compounding becomes essential. It represents a return to the historical roots of pharmacy, where a medication is created specifically for an individual’s needs. This stands in contrast to large-scale pharmaceutical manufacturing, which is designed to produce standardized medications for the general population. Each approach has a distinct purpose and operates under a different framework of oversight, a reality born from decades of evolving law and science.

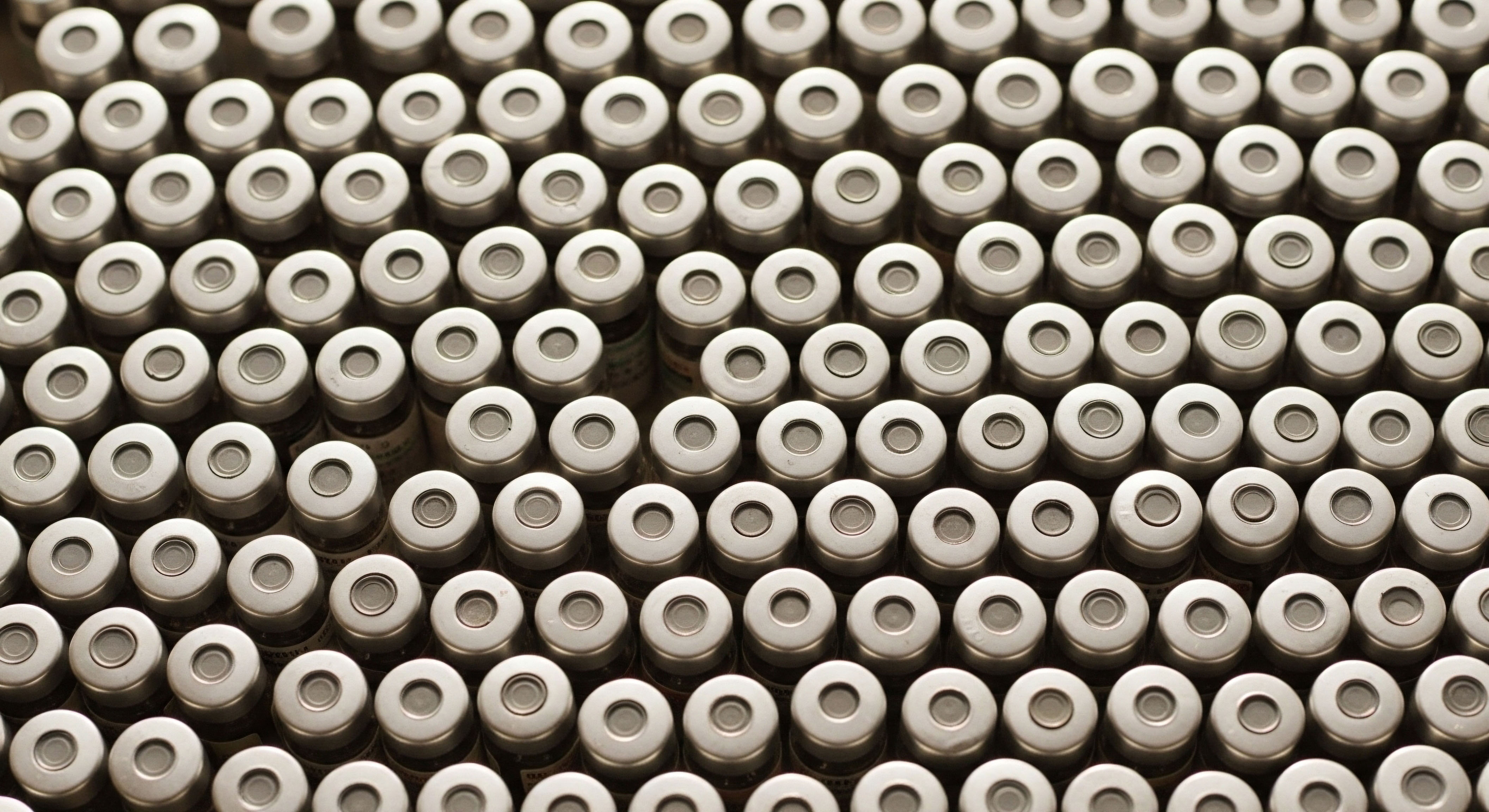

A compounded medication is tailored to an individual patient, while a manufactured drug is created for a mass market.

To appreciate the landscape of hormonal health solutions, it is beneficial to understand the governing bodies that ensure the quality and safety of your medications. The U.S. Food and Drug Administration (FDA) is the primary federal agency responsible for overseeing the drug manufacturing industry. Its mandate is to ensure that mass-produced drugs are both safe and effective for their intended use through a rigorous, multi-year approval process. Compounding pharmacies, historically, have been regulated primarily by individual State Boards of Pharmacy. This structure acknowledges compounding as an integral part of state-licensed pharmacy practice. The United States Pharmacopeia (USP) further provides critical standards for compounding quality, creating a baseline for processes and procedures that protect patient health. These three entities, the FDA, State Boards of Pharmacy, and the USP, form the regulatory architecture that governs how your specific hormonal therapies are prepared.

The Patient’s Need for Customization

The human endocrine system is a complex web of interconnected signals. Your unique physiology, genetics, and life circumstances dictate your specific hormonal needs. A one-size-fits-all approach is often insufficient for achieving optimal balance. This is why a physician might prescribe a compounded medication. Consider a male patient on a TRT protocol. The standard concentration of Testosterone Cypionate might be 200mg/ml, but his specific needs, based on detailed lab work, may require a 150mg/ml concentration to achieve ideal serum levels without side effects. A compounding pharmacy can formulate this precise concentration.

Similarly, a perimenopausal woman may benefit from a low dose of topical testosterone for libido and energy, combined with a specific ratio of bioidentical progesterone. Commercial products with this exact formulation may not exist. A compounding pharmacist, working from a physician’s prescription, can create a single cream containing the precise ingredients in the necessary doses. Other common reasons for compounding include:

- Allergies ∞ A patient may be allergic to a dye, preservative, or filler (like gluten or lactose) used in a mass-produced tablet like Anastrozole. A compounding pharmacy can prepare the active ingredient in a capsule with a hypoallergenic filler.

- Dosage Form ∞ A patient may have difficulty swallowing pills. A compounding pharmacist can potentially formulate the medication as a liquid, topical cream, or sublingual troche.

- Combination Therapies ∞ For protocols involving multiple agents, such as certain peptide therapies like Sermorelin and Ipamorelin, a compounding pharmacy can sometimes combine them into a single injection, simplifying the treatment regimen under a physician’s guidance.

Regulatory Foundations a Tale of Two Systems

The regulatory pathways for manufactured and compounded drugs diverged to serve two different ends. The modern pharmaceutical industry, with its capacity for immense scale, required a centralized, rigorous approval process to protect public health. The Federal Food, Drug, and Cosmetic Act of 1938, and its subsequent amendments, established the FDA’s authority, demanding that manufacturers prove the safety and efficacy of new drugs before they reach the market. This process involves extensive clinical trials and can take many years and hundreds of millions of dollars per drug. It is a system built for standardization and large populations.

Compounding, in its traditional form, is an extension of the doctor-patient-pharmacist triad. It is a specific solution for a specific person. Subjecting each unique compounded prescription to the full FDA approval process would be impossible and would eliminate the practice of personalized medicine altogether. Consequently, federal law, specifically section 503A of the FD&C Act, exempts compounded drugs prepared for an individual patient from the FDA’s pre-market approval and manufacturing requirements, placing primary oversight with the states. This legal framework is designed to preserve access to customized medications while establishing a distinct regulatory channel. It acknowledges that the role of a compounding pharmacist is to prepare a unique medication for a patient, not to act as a large-scale manufacturer.

Intermediate

As you deepen your understanding of personalized medicine, the distinction between different types of compounding pharmacies becomes critically important. The regulatory landscape is not monolithic; it contains a crucial division established by Congress to address different scales of compounding. This division is between 503A and 503B facilities. Your prescribed testosterone, progesterone, or peptide therapy will likely originate from one of these two types of pharmacies, and their operating standards are substantially different. Making an informed choice about your health protocol involves understanding what these designations mean for the quality, testing, and oversight of your medications.

The creation of this two-tiered system was a direct response to public health events and the evolving needs of the healthcare system. Traditional compounding, performed in a local pharmacy for a specific patient with a prescription, is defined under Section 503A of the Food, Drug, and Cosmetic Act. However, hospitals and clinics often need larger supplies of commonly used compounded medications, such as specific intravenous solutions or injectable pain medications, without having individual patient prescriptions in hand. To fill this need and provide a higher level of federal oversight, Section 503B was created, establishing “Outsourcing Facilities.” These 503B facilities can produce large batches of compounded drugs and are held to a more stringent set of federal standards.

What Are the Core Differences in Pharmacy Oversight

The fundamental distinction between a 503A and a 503B facility lies in their regulatory requirements and intended scope of practice. A 503A pharmacy is a traditional compounding pharmacy that formulates medications based on a valid prescription for an individual patient. A 503B facility, on the other hand, functions as a hybrid between a pharmacy and a manufacturer, voluntarily registering with the FDA as an outsourcing facility. This registration subjects them to a higher level of federal scrutiny.

The most significant difference is the manufacturing standard to which they must adhere. 503B outsourcing facilities must comply with the FDA’s Current Good Manufacturing Practices (cGMP). These are the same rigorous standards that large pharmaceutical manufacturers like Pfizer or Merck must follow. cGMP governs every aspect of production, including personnel qualifications, facility design, process validation, equipment calibration, and extensive product testing. 503A pharmacies are not required to comply with cGMP. Instead, they are primarily regulated by State Boards of Pharmacy and are expected to follow the standards set forth in the United States Pharmacopeia (USP) chapters, such as USP 795 for non-sterile preparations and USP 797 for sterile preparations.

A 503B facility operates under the FDA’s cGMP standards, while a 503A pharmacy follows state-regulated USP guidelines.

This divergence in standards has direct implications for your treatment. For example, a physician’s office might purchase a batch of Testosterone Cypionate injections for in-office administration from a 503B facility. This allows them to have a supply of a high-quality, federally inspected product on hand. Conversely, if you require a testosterone cream with a unique dose and a specific base because of a skin sensitivity, your prescription would be sent to a 503A pharmacy to be created specifically for you.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility | Pharmaceutical Manufacturer |

|---|---|---|---|

| Primary Oversight | State Boards of Pharmacy | U.S. Food and Drug Administration (FDA) | U.S. Food and Drug Administration (FDA) |

| Governing Standard | USP Chapters (<795>, <797>, <800>) | cGMP (Current Good Manufacturing Practices) | cGMP (Current Good Manufacturing Practices) |

| Prescription Requirement | Required for each specific patient | Not required for batch production | Not applicable (produces approved drugs) |

| Batch Production | Limited quantities in anticipation of prescriptions | Permitted to produce large batches | Standard practice |

| FDA Registration | Not required | Required | Required |

| Adverse Event Reporting | Varies by state requirements | Mandatory reporting to FDA | Mandatory reporting to FDA |

A Deeper Look at USP Compounding Standards

For 503A pharmacies, the USP chapters provide the foundational guidelines for ensuring medication quality. These standards are detailed documents that outline the minimum requirements for safe and effective compounding. They represent the consensus of scientific experts and are enforced by state pharmacy boards.

- USP Chapter 795 (Non-Sterile Preparations) ∞ This chapter governs the compounding of medications like capsules, tablets, creams, and oral liquids. It sets standards for ingredient sourcing, personnel training, facility cleanliness, and record-keeping. It also provides guidance on assigning beyond-use dates (BUDs) to ensure the medication remains stable and potent for a specified period. For instance, a compounded progesterone oral capsule would be prepared according to USP 795 standards.

- USP Chapter 797 (Sterile Preparations) ∞ This is a far more stringent standard that applies to any medication that will be injected, infused, or instilled in the eye. This includes injectable TRT, peptide therapies like CJC-1295/Ipamorelin, and Gonadorelin. USP 797 requires a controlled environment, including the use of cleanrooms with specialized air filtration systems (HEPA filters) to prevent microbial contamination. It mandates rigorous protocols for personnel garbing, aseptic technique, and sterility testing of the final product.

- USP Chapter 800 (Hazardous Drugs) ∞ This chapter provides standards for handling hazardous drugs to protect healthcare personnel, patients, and the environment. Certain hormones and related medications, like Anastrozole, can be classified as hazardous. USP 800 requires specific handling procedures, personal protective equipment (PPE), and facility designs to contain any potentially harmful particles or fumes.

The cGMP Gold Standard for 503b Facilities

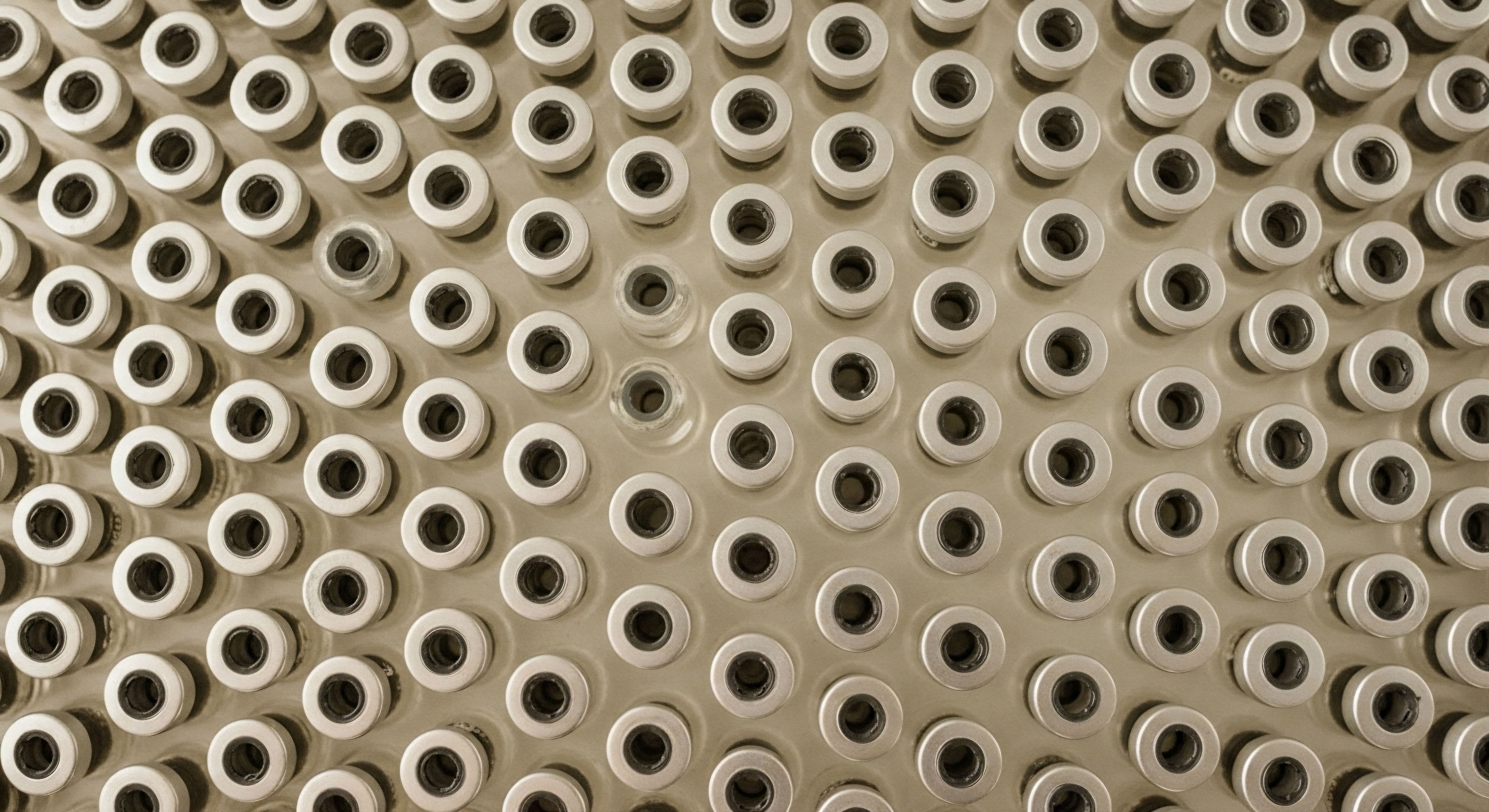

Current Good Manufacturing Practices (cGMP) represent a comprehensive quality system that goes beyond the baseline requirements of the USP chapters. Compliance with cGMP ensures that drugs are produced and controlled according to the highest quality standards. For a 503B outsourcing facility, this means every single process is meticulously documented and validated. Validation is a formal process of proving that a procedure, process, or piece of equipment will consistently produce the expected result.

For example, before a 503B facility can sell a batch of a growth hormone peptide like Sermorelin, it must have performed extensive validation studies. This includes validating the analytical chemistry methods used to test the peptide’s potency and purity. It must prove that its sterilization process consistently renders the product free of microbes. It must conduct stability studies to scientifically justify the beyond-use date on the label. This level of rigor provides a high degree of assurance about the identity, strength, quality, and purity of the product. This is why hospitals and large clinics rely on 503B facilities for their stock of compounded medications.

Academic

The distinction between pharmaceutical manufacturing and compounding is rooted in the statutory framework of the Federal Food, Drug, and Cosmetic Act (FD&C Act). This legal architecture creates a bifurcation in oversight, quality systems, and evidentiary requirements for demonstrating product safety and efficacy. From a clinical and biochemical perspective, these differences have profound implications for patient outcomes, particularly in endocrinology, where treatment protocols demand high precision in dosing and molecular integrity. An examination of the scientific principles behind Current Good Manufacturing Practices (cGMP) versus the standards of the United States Pharmacopeia (USP) reveals the granular differences in quality assurance that can impact the therapeutic action of a hormonal agent.

Pharmaceutical manufacturing operates on a paradigm of proactive quality assurance. The cGMP regulations, codified in 21 CFR Parts 210 and 211, mandate a systems-based approach where quality is built into the product at every stage. This is achieved through rigorous process validation, where each step of the manufacturing process is shown to be reproducible and consistently yield a product of predetermined quality. Compounding, particularly under the 503A framework, traditionally operates on a reactive quality control model, where the final preparation is tested to meet certain specifications. While 503B facilities bridge this gap by adhering to cGMP, the majority of patient-specific compounded hormonal therapies originate in 503A pharmacies, making an understanding of the USP standards and their limitations essential.

How Do Quality Systems Impact Hormonal Bioavailability?

The therapeutic efficacy of a hormone, be it Testosterone Cypionate for TRT or a delicate peptide like Tesamorelin, is contingent on its biochemical structure and the purity of the final formulation. The cGMP framework mandates stringent control over raw material sourcing, requiring vendors to be qualified and each batch of active pharmaceutical ingredient (API) to be tested for identity, purity, and strength before it enters the manufacturing stream. Impurities, such as residual solvents from synthesis or related substances from degradation, can have unintended biological effects or alter the pharmacokinetics of the primary molecule.

For example, in a cGMP facility, the high-performance liquid chromatography (HPLC) method used to confirm the potency of a batch of Anastrozole would itself be fully validated for specificity, linearity, accuracy, and precision. This ensures that the test reliably quantifies the active drug and can separate it from any potential degradants. In a 503A pharmacy following USP standards, while testing is required, the level of analytical method validation is less prescriptive. This introduces a potential for greater variability, which can be clinically significant when dealing with potent hormones where minor deviations in dosage can shift a patient from a therapeutic to a sub-therapeutic or supra-physiologic state. The endocrine system’s reliance on sensitive negative feedback loops, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis, means that inconsistent dosing can lead to erratic downstream signaling and a failure to achieve therapeutic goals.

The cGMP framework mandates proactive process validation, whereas USP standards for 503A pharmacies focus on final product quality control.

Sterility and Endotoxin Testing a Critical Distinction

For all injectable therapies, including hormonal and peptide protocols, sterility is a non-negotiable parameter. Both USP 797 and cGMP require sterility. However, the requirements for demonstrating and maintaining that sterility differ in their systematic depth. cGMP requires that the entire sterilization process, such as steam autoclaving or sterile filtration, be validated to prove its effectiveness and reproducibility. This includes container-closure integrity testing to ensure the vial and stopper prevent microbial ingress over the product’s shelf life.

A particularly critical parameter for injectable drugs is the bacterial endotoxin level. Endotoxins are lipopolysaccharides from the cell walls of gram-negative bacteria and can cause a severe inflammatory response, fever, and even shock if injected. The cGMP standard requires robust testing of raw materials and the final product for endotoxins using a validated Limulus Amebocyte Lysate (LAL) test. While USP 797 also requires endotoxin testing for certain high-risk compounded sterile preparations, the cGMP framework within a 503B facility or a manufacturer provides a more comprehensive system of prevention and control. For a patient on a daily subcutaneous peptide protocol, such as Ipamorelin/CJC-1295, the cumulative burden of even low levels of endotoxin from a preparation with inconsistent quality control could contribute to systemic inflammation, undermining the anti-aging and wellness goals of the therapy.

| Quality Attribute | USP Standards (Typical for 503A) | cGMP Standards (Required for 503B & Manufacturers) |

|---|---|---|

| API Identity/Purity | Relies on Certificate of Analysis (CoA) from supplier; may perform identity tests. | Requires independent verification of API identity, purity, and strength. Full CoA validation. |

| Potency Testing | Required for final product. Analytical method is not required to be fully validated. | Requires use of a fully validated, stability-indicating analytical method (e.g. HPLC). |

| Sterility Assurance | Follows USP <797> procedures. Focus on aseptic technique and end-product testing. | Requires full validation of the entire sterilization process. Comprehensive environmental monitoring. |

| Endotoxin Control | Testing required for high-risk sterile compounds. | Systematic control and testing of components and final product. Validated LAL testing. |

| Stability/BUD | Beyond-Use Date (BUD) often based on USP chapter defaults or available literature. | Expiration date must be supported by rigorous, real-time stability studies for each formulation. |

The Legal Precedent and Its Scientific Aftermath

The legislative distinction between 503A and 503B was solidified by the Drug Quality and Security Act (DQSA) of 2013. This law was a direct congressional response to the 2012 fungal meningitis outbreak traced back to the New England Compounding Center (NECC), a state-licensed pharmacy that was functioning as a large-scale, unregistered drug manufacturer. Contaminated methylprednisolone acetate injections led to hundreds of infections and dozens of deaths. The investigation revealed egregious lapses in quality control and a disregard for sterile compounding procedures. NECC was operating in a grey area, producing large batches of sterile drugs without patient-specific prescriptions and without adhering to cGMP standards or FDA oversight.

The creation of the 503B “Outsourcing Facility” category was designed to close this regulatory gap. It provided a clear pathway for facilities wishing to produce compounded medications in bulk to register with the FDA and be held to the higher cGMP standard. This event underscores the profound public health consequences of inadequate quality control in compounding. From a scientific standpoint, it highlights that the procedures outlined in USP 797, while providing a crucial baseline for safety, may be insufficient when compounding is performed at a large scale without the accompanying systems-based quality assurance framework of cGMP. For the individual seeking personalized hormonal therapy, this history serves as a critical reminder of the importance of choosing a compounding pharmacy, whether 503A or 503B, that demonstrates an unwavering commitment to quality and transparency.

References

- Burt’s Pharmacy. “Differences Between Pharmaceutical Manufacturing and Compounding.” 6 Jan. 2018.

- Tennessee Poison Center. “What is the law regarding pharmacy compounding versus drug manufacturing?” 17 Dec. 2012.

- Brookings Institution. “FDA oversight of drug manufacturing and compounding ∞ A comparison.” 19 Dec. 2024.

- National Academies of Sciences, Engineering, and Medicine. “Compounded Topical Pain Creams ∞ Gaps in Regulation, Oversight, and Surveillance.” The National Academies Press, 2020.

- National Academies of Sciences, Engineering, and Medicine. “The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence.” The National Academies Press, 2020.

- “Deciphering USP 795 requirements.” HFM Magazine, 6 Dec. 2017.

- Wolters Kluwer. “USP 797 and USP 795 ∞ Creating and Managing a State of Control.”

- National Association of Boards of Pharmacy. “Compounding Pharmacy Accreditation | USP Chapter 797 & 795.” 16 Oct. 2024.

- “503A vs. 503B ∞ A Quick-Guide to Compounding Pharmacy Designations & Regulations.” ARL Bio Pharma, 16 Nov. 2021.

- “Understanding the differences between 503A, 503B compounding pharmacies.” TechTarget, 10 June 2024.

Reflection

Charting Your Own Biological Course

You have now explored the intricate systems that govern how personalized medications are made. This knowledge of regulatory frameworks, from state-governed USP standards to the federal rigor of cGMP, is more than academic. It is a practical toolset for navigating your own health decisions with confidence. Understanding the source of your therapy is as important as the therapy itself. This information equips you to ask informed questions, evaluate your options, and engage with your clinical team as a true partner in your wellness. Your path to hormonal optimization is unique. The biological data from your lab results tells one part of the story; your lived experience tells the other. The true goal is to align these two narratives, creating a state of vitality that is both measurable and felt. This journey is yours to direct, armed with the clarity that comes from understanding the science of your own well-being.