Fundamentals

You arrive at a point in your health journey where the standard answers no longer seem to fit the questions your body is asking. You feel a persistent fatigue that sleep doesn’t resolve, a mental fog that clouds your focus, or a subtle but unyielding shift in your vitality.

Your lab results may hover in the “normal” range, yet your lived experience tells a different story. This is the space where personalized medicine begins, and it is the precise reason understanding the distinction between mass-produced pharmaceuticals and compounded medications becomes a cornerstone of your empowerment.

Your body is a unique biological system, an intricate network of signals and responses. The path to optimizing its function often requires a tool built for its specific needs, not one designed for the statistical average of a population.

The journey of a standard drug from a laboratory to your local pharmacy is a testament to a system designed for large-scale public safety. This process, overseen by the U.S. Food and Drug Administration (FDA), is a monumental undertaking of scientific validation.

It begins with preclinical research, where a potential drug molecule is tested in non-human models to establish its basic safety profile. Following this, the drug enters a series of human clinical trials, each with a distinct and critical purpose.

Phase I trials typically involve a small group of healthy volunteers to assess safety, dosage, and how the drug moves through the human body. Phase II trials expand to a larger group of individuals who have the condition the drug is intended to treat, providing the first real data on its effectiveness.

Phase III trials are the largest and most rigorous, involving thousands of participants to confirm effectiveness, monitor side effects, and compare it to existing treatments. Only after successfully navigating these demanding phases can a manufacturer submit a New Drug Application (NDA) to the FDA.

This dossier is a mountain of data, which the agency’s scientists meticulously review before granting approval for public use. This entire sequence is built on a single premise ∞ to ensure a medication is safe and effective for the broadest possible population.

The FDA’s approval process for manufactured drugs is a multi-stage marathon of clinical trials designed to validate safety and efficacy for millions of people.

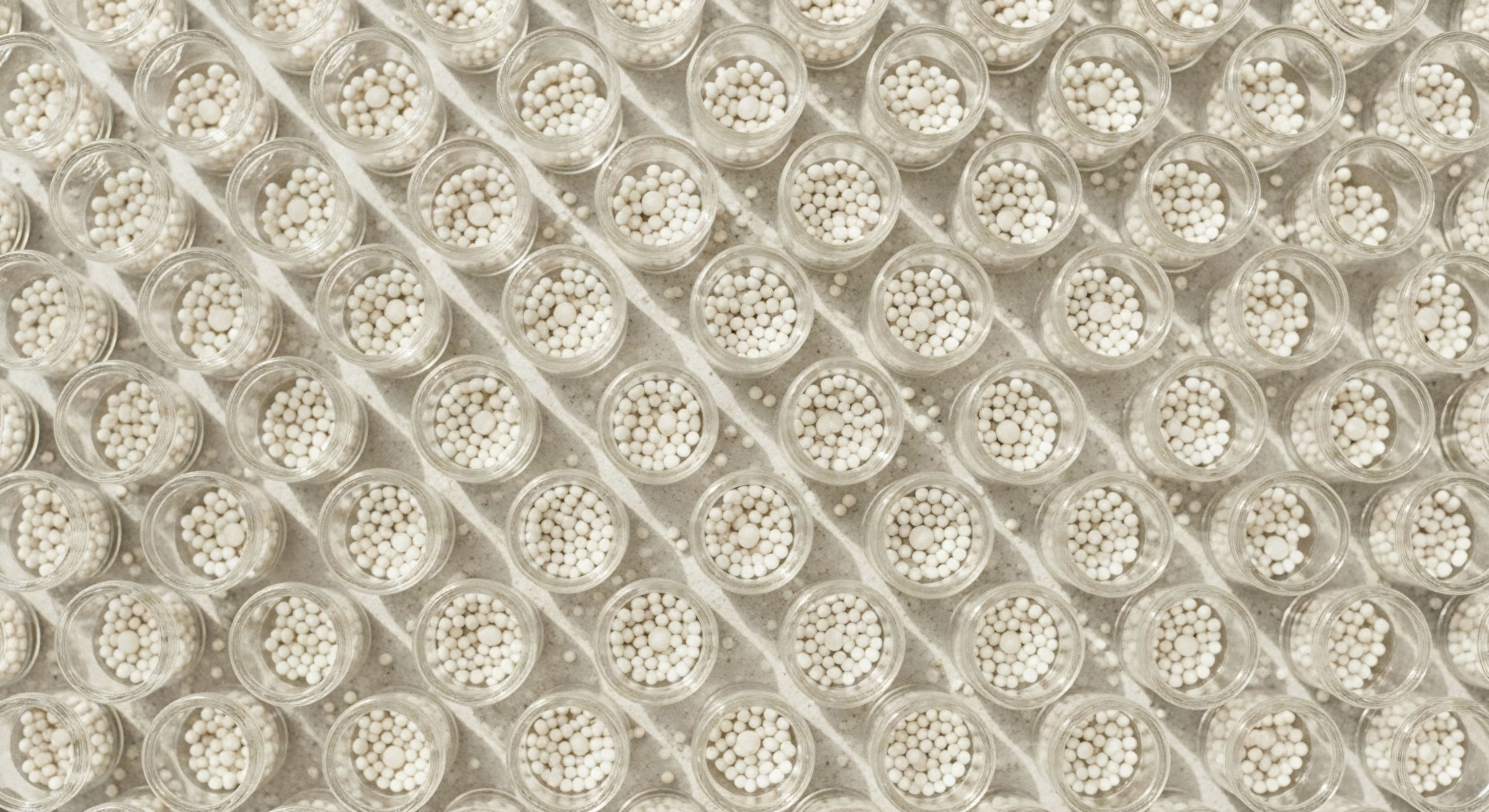

Compounding, in contrast, operates from a fundamentally different philosophy. It is the art and science of creating a personalized medication for a single individual. A compounding pharmacist, working on the instruction of a prescribing clinician, combines or alters ingredients to create a formulation that is unavailable commercially.

This practice exists because human biology is not uniform. A patient may have an allergy to a specific dye, filler, or preservative used in a mass-produced pill. A child or an elderly individual might require a liquid version of a drug that only comes in a large tablet.

In the realm of hormonal health, the need is even more pronounced. Your endocrine system is a finely tuned orchestra, and achieving balance may require a dosage of testosterone, progesterone, or thyroid hormone that simply is not manufactured. It may involve combining several active ingredients or creating a delivery system, like a topical cream or a subcutaneous injection, that is tailored to your body’s absorption patterns and your lifestyle.

This personalization creates a unique regulatory structure. Compounded medications are not FDA-approved. The agency does not individually vet each customized prescription for safety and efficacy in the way it does for a manufactured drug. This reality does not signify an absence of rules. Instead, it shifts the primary oversight responsibility.

The regulatory framework for compounding is rooted in state-level governance, primarily through State Boards of Pharmacy. These bodies license pharmacists and pharmacies, setting standards for practice within their jurisdiction. They are the frontline regulators, ensuring that compounding is performed safely and ethically, meeting the direct needs of patients as prescribed by their doctors.

This system acknowledges the unique relationship between the patient, the prescriber, and the pharmacist ∞ a triad of care focused on a specific, individual outcome. It is a world of bespoke solutions, and its regulations are designed to govern that specific context, distinct from the world of mass production.

The Patient Centered Rationale

The decision to use a compounded medication originates from a clinical need that cannot be met by an FDA-approved product. Consider the protocol for Testosterone Replacement Therapy (TRT) in men. A standard protocol might involve weekly injections of Testosterone Cypionate.

While some manufactured vials are available, a compounding pharmacy can prepare syringes with the precise dosage prescribed for you, minimizing waste and ensuring consistency. They can also compound adjunctive therapies like Gonadorelin or Anastrozole in the exact strengths and forms needed to maintain your body’s delicate hormonal feedback loops.

For women navigating perimenopause, the need is even more specific. A physician might determine you need a very low dose of testosterone for libido and energy, combined with a specific ratio of bioidentical progesterone. These precise formulations are not available from large manufacturers; they must be compounded.

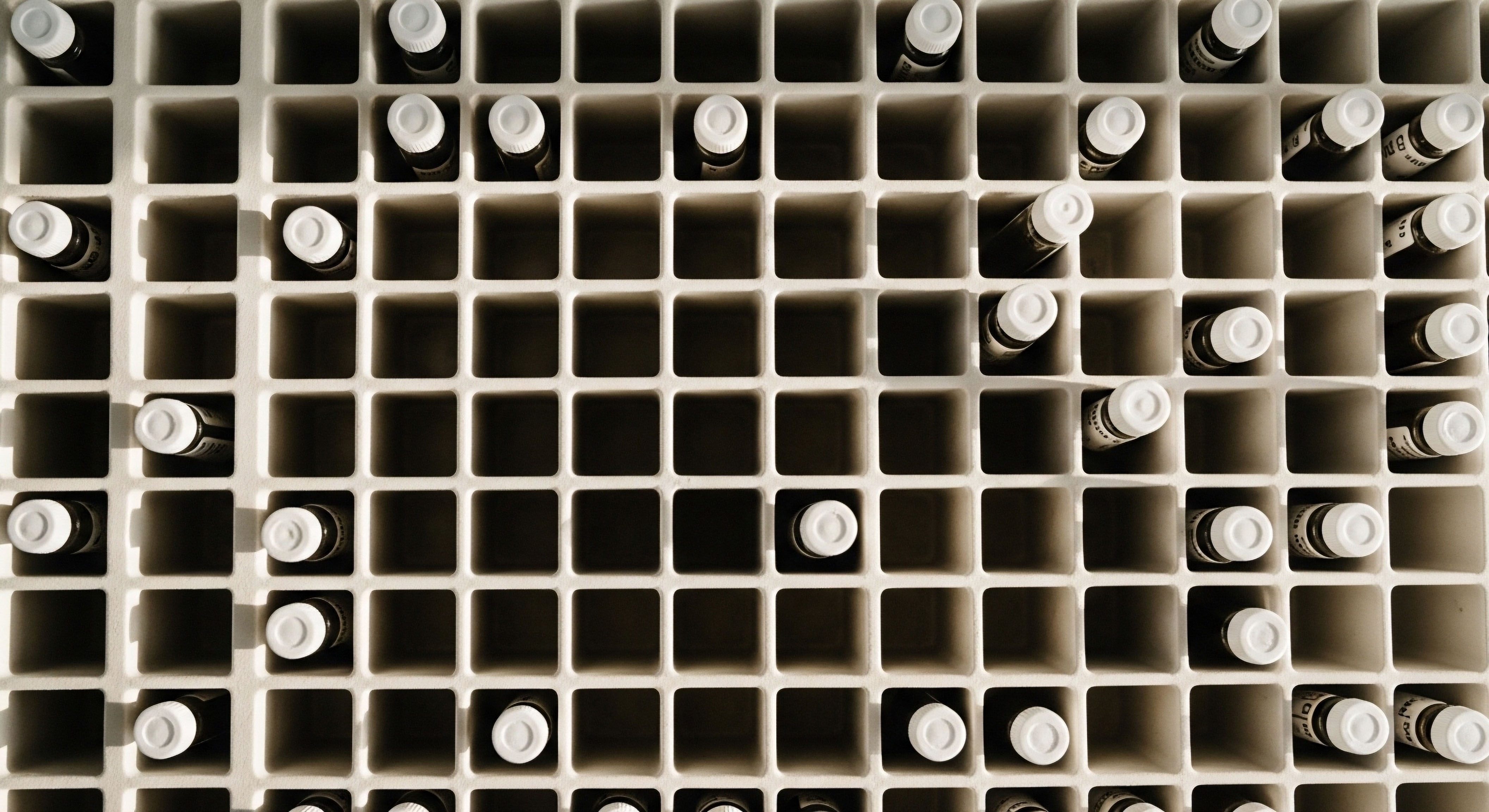

Peptide therapies represent another frontier where compounding is essential. Peptides like Ipamorelin, CJC-1295, or PT-141 are chains of amino acids that act as signaling molecules in the body. They are often used to support the body’s natural production of growth hormone or to target specific pathways for tissue repair and sexual health.

Because these are specialized therapies tailored to an individual’s wellness goals, they are prepared by compounding pharmacies. The regulatory system allows for this innovation, providing access to cutting-edge protocols under the care of a knowledgeable clinician and a trusted pharmacist. The entire framework is built to serve the individual, acknowledging that your biology, your symptoms, and your path to wellness are uniquely your own.

Intermediate

To truly grasp the operational differences between compounded medications and standard drugs, one must examine the legal architecture that defines their paths to the patient. This structure was significantly reshaped by a critical piece of legislation, the Drug Quality and Security Act (DQSA) of 2013.

Enacted in response to a public health crisis linked to a large-scale compounding pharmacy, the DQSA clarified the FDA’s authority and created two distinct categories of compounders, each with its own set of rules, limitations, and oversight mechanisms. These categories, known as 503A and 503B, form the legal bedrock of modern compounding and stand in sharp contrast to the process for conventional drug manufacturers.

A conventional pharmaceutical manufacturer operates under the full authority of the FDA. Before a single pill can be sold, the company must complete the arduous New Drug Application (NDA) process, proving safety and efficacy through extensive clinical trials.

Manufacturing facilities are subject to the FDA’s Current Good Manufacturing Practices (CGMP), a comprehensive set of regulations governing every aspect of production, from raw material sourcing to facility design and process controls. Labeling must be standardized and provide adequate directions for use, and a robust system for reporting adverse events directly to the FDA is mandatory. This is a system designed for industrial-scale production and national distribution, with federal oversight at every step.

Section 503a Compounding Pharmacies

Section 503A of the FD&C Act pertains to traditional compounding pharmacies ∞ the local pharmacy or specialized practitioner that creates a medication for a specific patient upon receiving a valid prescription. This is the historical foundation of pharmacy practice. Under 503A, these pharmacies are granted exemptions from three key FDA requirements ∞ new drug approval, CGMP, and standardized labeling with adequate directions for use.

These exemptions are granted because the practice is defined by its small scale and patient-specific nature. A 503A pharmacy is compounding in response to a direct clinical need identified by a prescriber for an individual. The primary regulatory authority for these pharmacies lies with the State Boards of Pharmacy, which handle licensing and inspections.

While the FDA can intervene if a 503A pharmacy engages in practices that violate the FD&C Act (such as creating drugs under insanitary conditions or compounding large volumes without individual prescriptions), their day-to-day oversight is deferred to the state.

They may also perform “anticipatory compounding,” preparing small batches of a medication in advance of receiving prescriptions, based on a history of receiving such orders. This entire framework is built on the triad of care ∞ the relationship between the patient, prescriber, and pharmacist.

The Drug Quality and Security Act established two distinct legal pathways for compounding, 503A for patient-specific prescriptions and 503B for larger-scale production under federal oversight.

Section 503b Outsourcing Facilities

The DQSA introduced a new entity ∞ the 503B outsourcing facility. These facilities were created to fill a gap between small-scale patient-specific compounding and large-scale pharmaceutical manufacturing. Hospitals, clinics, and physician offices often need larger quantities of compounded medications, particularly sterile preparations like injectable hormones or IV solutions, to have on hand for immediate use. A 503B facility can produce these medications in bulk without receiving patient-specific prescriptions, a practice known as “office use.”

To operate in this manner, a facility must voluntarily register with the FDA as a 503B outsourcing facility and is subject to a different, more stringent set of rules. While they are still exempt from the full new drug approval process and certain labeling requirements, they are not exempt from CGMP.

503B facilities must adhere to these federal manufacturing standards, ensuring a higher level of quality control and consistency across larger batches. They are also subject to routine FDA inspections on a risk-based schedule and are required to report adverse events to the agency, just like a conventional drug manufacturer.

This dual system creates a clear distinction ∞ if a medication is compounded for an individual patient based on a prescription, it falls under 503A and state oversight. If it is compounded in bulk for office use, it falls under 503B and direct FDA oversight.

How Do Regulatory Pathways Influence Hormonal Therapies?

This dual framework directly impacts how personalized hormonal and peptide therapies are provided. Many patients receiving Testosterone Replacement Therapy (TRT) or bioidentical hormone treatments get their prescriptions filled at a 503A pharmacy. The clinician determines the precise dosage of Testosterone Cypionate, Anastrozole, or Progesterone, and the 503A pharmacy compounds it specifically for that patient. The safety and quality of that specific prescription are governed by the standards of the pharmacist and the oversight of the state board.

A large wellness clinic, however, might contract with a 503B outsourcing facility to supply it with pre-filled syringes of a common TRT protocol or batches of a popular peptide combination like Ipamorelin/CJC-1295. By doing so, the clinic gains the assurance that the medications were produced in an FDA-registered facility that complies with federal CGMP standards.

This is particularly critical for sterile injectable drugs, where the risk of contamination is highest. The choice between using a 503A or 503B facility becomes a clinical and operational decision, balancing the need for true individualization against the quality assurance that comes with federal manufacturing oversight.

| Feature | Standard Drug Manufacturer | 503B Outsourcing Facility | 503A Compounding Pharmacy |

|---|---|---|---|

| Primary Oversight Body | U.S. Food and Drug Administration (FDA) | U.S. Food and Drug Administration (FDA) | State Boards of Pharmacy |

| Prescription Requirement | Not applicable; available via prescription after approval. | Patient-specific prescription not required; can produce for “office use”. | Valid patient-specific prescription required. |

| Pre-Market Approval | Full New Drug Application (NDA) process required. | Exempt from NDA process. | Exempt from NDA process. |

| Manufacturing Standards | Must comply with Current Good Manufacturing Practices (CGMP). | Must comply with Current Good Manufacturing Practices (CGMP). | Exempt from CGMP; follows state and USP standards. |

| Adverse Event Reporting | Mandatory reporting to FDA. | Mandatory reporting to FDA. | No federal requirement; may have state-level requirements. |

| Scale of Production | Large-scale, mass production for national/global distribution. | Large-batch production without individual prescriptions. | Small-scale, individual-patient compounding. |

- Standard Manufacturers ∞ These entities invest hundreds of millions of dollars and years of research to bring a single drug to market. Their regulatory burden is immense, but it provides a high degree of certainty about the product’s safety, efficacy, and consistency for the general population.

- 503B Facilities ∞ These organizations serve as a bridge. They operate under federal oversight and must follow the same manufacturing quality standards as major drug companies, providing a reliable source of commonly used compounded medications for healthcare facilities. They are a direct result of the need for quality-assured, sterile compounds at scale.

- 503A Pharmacies ∞ These are the artisans of the pharmaceutical world. They provide the ultimate in personalization, creating medications one-by-one to solve unique patient problems. Their regulation is localized, reflecting the intimate nature of the patient-pharmacist-prescriber relationship.

Academic

A sophisticated analysis of pharmaceutical regulation reveals two parallel philosophies of risk management. The conventional FDA drug approval pathway is a population-level public health strategy. It is predicated on mitigating risk for millions by demanding exhaustive statistical evidence of safety and efficacy before a product reaches the market.

The regulatory framework for compounding, however, represents a patient-level clinical strategy. It accepts the reality of biological individuality and provides a structured, albeit different, system for managing the risks associated with creating bespoke therapeutic agents. The divergence between these systems is most apparent when examining the concepts of quality, sterility, and the application of advanced hormonal and peptide protocols from a systems-biology perspective.

The bedrock of quality in conventional drug manufacturing is Current Good Manufacturing Practices (CGMP). These are not merely suggestions; they are enforceable regulations that dictate process validation, raw material testing, facility environmental controls, and batch-to-batch consistency. For a 503B outsourcing facility, adherence to CGMP is also mandatory, providing a standardized assurance of quality for sterile products made in bulk.

For a 503A compounding pharmacy, the landscape is more varied. While exempt from federal CGMP, they are expected to comply with standards set by their State Boards of Pharmacy, which often reference chapters from the United States Pharmacopeia (USP), such as USP <795> for non-sterile compounding and USP <797> for sterile compounding.

These chapters provide detailed procedures for maintaining quality, but the stringency of enforcement can vary by state. This creates a spectrum of quality assurance, from the federally mandated uniformity of manufacturers and 503B facilities to the state-regulated practices of 503A pharmacies.

What Are the Implications for Sterile Compounding?

The distinction is critically important in the context of sterile compounding, which includes the injectable hormone and peptide therapies central to personalized wellness protocols. The 2012 fungal meningitis outbreak, which originated from the New England Compounding Center (NECC), was a catastrophic failure of sterile compounding practices.

It was this event that directly precipitated the passage of the DQSA. It highlighted the profound public health risk when a facility operates in the gray area between a traditional pharmacy and a manufacturer, producing contaminated sterile products at a large scale. The creation of the 503B category was a direct legislative response, designed to bring any entity compounding sterile drugs in bulk under the stringent oversight of the FDA and CGMP requirements.

For a patient, this means the source of their compounded sterile medication matters. A Testosterone Cypionate injection prepared at a 503A pharmacy is formulated for them alone, and its sterility depends on that pharmacist’s adherence to USP <797> standards and state regulations.

An identical injection sourced by a clinic from a 503B outsourcing facility was produced as part of a large batch, with its sterility assured by federally mandated CGMP. Both pathways are legal and serve different needs, but they represent different models of quality assurance. An informed patient and clinician will consider this distinction, potentially seeking out 503A pharmacies with additional credentials, such as accreditation from the Pharmacy Compounding Accreditation Board (PCAB), which signifies a higher commitment to quality standards.

The regulatory divergence between 503A and 503B facilities reflects a fundamental split in risk management, balancing patient-specific customization against the quality assurances of federal manufacturing standards.

A Systems Biology View of Hormonal Optimization

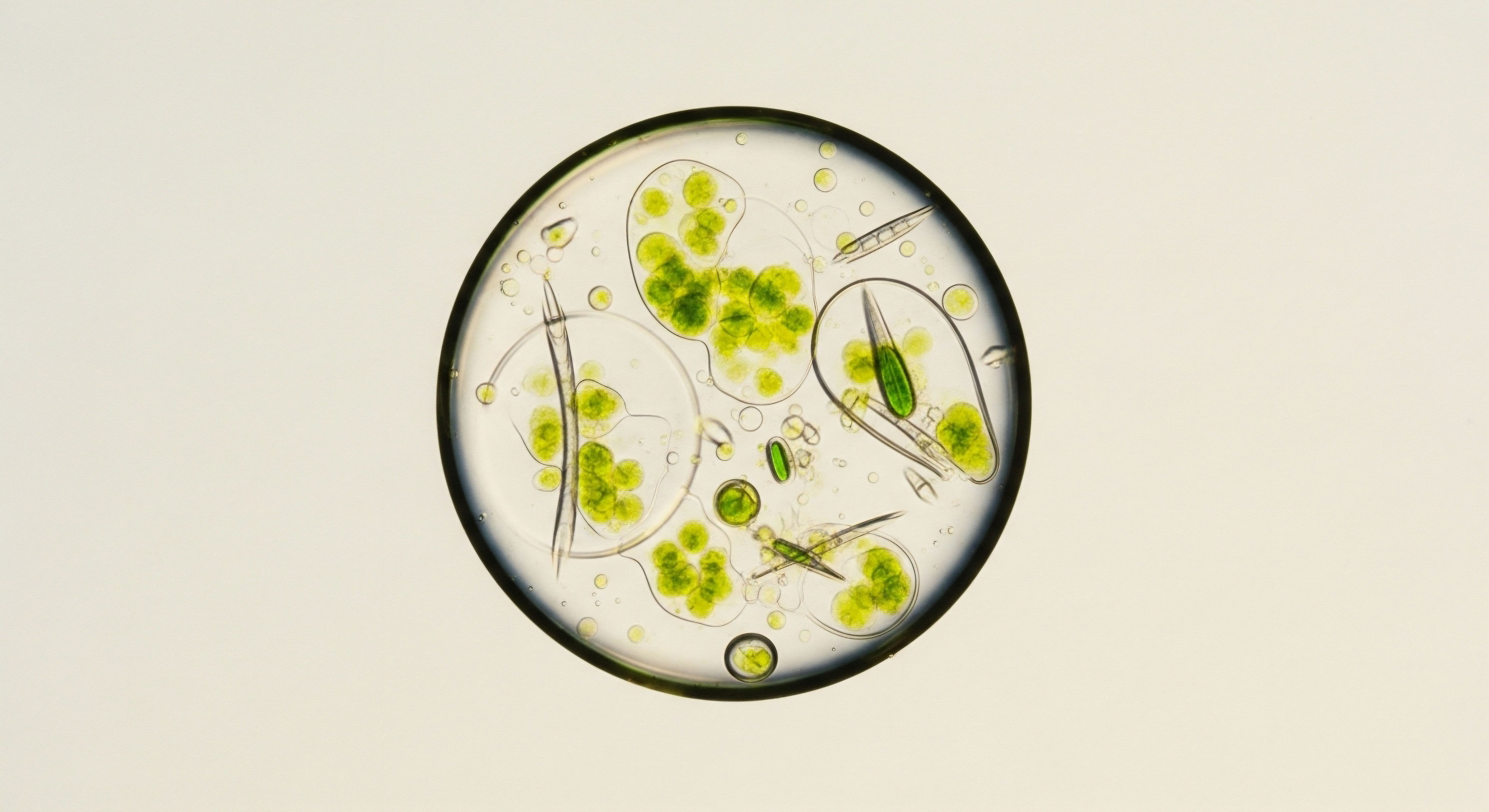

The regulations also reflect a deeper biological truth. Standard drug approval is often geared towards treating a single pathology with a single agent. Hormonal optimization, however, is a practice rooted in systems biology. It acknowledges that the endocrine system is a complex, interconnected web of feedback loops.

Optimizing one hormone, like testosterone, inevitably impacts others, such as estradiol and luteinizing hormone (LH). Effective protocols, therefore, are rarely about a single drug. They are about a coordinated intervention designed to re-calibrate an entire system.

A typical TRT protocol for a male might include:

- Testosterone Cypionate ∞ To directly increase serum testosterone levels.

- Anastrozole ∞ An aromatase inhibitor to control the conversion of testosterone to estradiol, managing potential side effects.

- Gonadorelin or HCG ∞ To stimulate the hypothalamic-pituitary-gonadal (HPG) axis, maintaining testicular function and endogenous hormone production.

This multi-component approach is inherently personalized. The precise dosages and ratios depend on an individual’s baseline lab values, their genetic predispositions, and their subjective response to treatment. Such a protocol cannot be packaged into a single, one-size-fits-all product for FDA approval.

It must be assembled and adjusted for the individual, a task perfectly suited for a compounding pharmacy. The regulatory framework for compounding enables this systems-based approach to medicine, allowing clinicians to design and implement sophisticated, multi-variable protocols that would be impossible to deliver through the conventional pharmaceutical pipeline.

The same principle applies to advanced peptide therapies. A protocol combining Ipamorelin (a Growth Hormone Releasing Peptide) with CJC-1295 (a Growth Hormone Releasing Hormone analogue) is designed to create a synergistic and more natural pulse of growth hormone release from the pituitary gland.

The efficacy of this combination relies on the specific properties of each peptide and the timing of their administration. Compounding is the only viable mechanism for providing such a targeted, multi-agent therapeutic strategy. The regulatory system, by providing the 503A and 503B pathways, creates a legal and operational space for this kind of advanced, personalized, and systems-oriented medicine to exist.

| Quality Domain | Standard Drug Manufacturer / 503B Facility | 503A Pharmacy |

|---|---|---|

| Potency & Purity | Federally mandated batch testing using validated methods like HPLC to ensure every batch meets precise specifications. Raw materials are rigorously tested before use. | Follows USP standards. Potency testing may be done periodically or upon request. Relies heavily on calculations and process integrity. |

| Sterility (for injectables) | CGMP-compliant cleanroom environments (ISO 5). Rigorous environmental monitoring and end-product sterility testing on every batch. | Must comply with USP <797> standards for sterile preparation, including use of laminar flow hoods and proper aseptic technique. End-product testing is less frequent. |

| Endotoxin Testing | Mandatory for all sterile batches to prevent pyrogenic reactions. | Recommended by USP <797> but implementation may vary. Crucial for patient safety. |

| Process Validation | Manufacturing processes are extensively validated to prove they consistently produce a quality product. | Relies on the skill and training of the individual pharmacist following established procedures. |

References

- U.S. Food and Drug Administration. “Compounding and the FDA ∞ Questions and Answers.” FDA, 15 Nov. 2024.

- “Compounded Medications ∞ Are They Legal, FDA-Approved, and Covered by Insurance?” GoodRx Health, 6 Sept. 2024.

- Committee on the Assessment of the Available Scientific Data Regarding the Safety and Effectiveness of Compounded Topical Pain Creams. “Gaps in Regulation, Oversight, and Surveillance.” Compounded Topical Pain Creams ∞ Review of the Evidence, National Academies Press, 2020.

- “Pros and Cons of Pharmacy Compounding.” U.S. Pharmacist, 1 Oct. 2022.

- “Who Regulates Compounding Pharmacies? Law & Oversight.” LookMeds, 10 Apr. 2025.

- “What are 503A and 503B compounding pharmacies?” DDReg, 2023.

- “Drug Quality and Security Act Creates New Laws for Compounding Pharmacies.” JD Supra, 12 Dec. 2013.

- “Drug Compounding ∞ FDA Authority and Possible Issues for Congress.” Congressional Research Service, 5 Jan. 2018.

- “Compounding Law Five Years Later ∞ FDA Implementation Slow, Industry Criticism Significant.” P&T, vol. 43, no. 5, 2018, pp. 277-299.

- “Drug Compounding & US FDA Regulatory Compliance.” AXSource, 13 May 2024.

Reflection

You have now traveled through the intricate architecture of pharmaceutical regulation. You have seen the towering structure of the FDA approval process, built to protect millions, and you have explored the tailored workshops of compounding pharmacies, designed to serve the individual.

This knowledge does more than simply answer a question; it equips you with a new lens through which to view your own health. It transforms you from a passive recipient of care into an active, informed collaborator in your own wellness. The path forward is one of dialogue and discovery, a partnership with a clinician who understands both the science of the human body and the art of personalization.

Where Does Your Journey Lead from Here?

Understanding these regulatory distinctions is the first step. The next is to ask deeper questions about your own biological system. What are your individual needs? What does your body’s data, from lab work to your daily experience, tell you? The protocols and therapies discussed here are powerful tools, and their application is a process of careful calibration.

Your journey is about finding the precise inputs that will allow your system to function with renewed vitality and resilience. The knowledge you have gained is your map and compass. The journey itself, however, is uniquely yours to chart, guided by expert hands and your own deepening understanding of the incredible biological machine you inhabit.

Glossary

compounded medications

personalized medicine

food and drug administration

new drug application

state boards of pharmacy

testosterone replacement therapy

testosterone cypionate

compounding pharmacy

peptide therapies

growth hormone

compounding pharmacies

current good manufacturing practices

503a pharmacy

503b outsourcing facility

503b facility

outsourcing facility

503b facilities

503b outsourcing

quality assurance

fda drug approval

good manufacturing practices

503a compounding pharmacy

sterile compounding

new england compounding center