Fundamentals

Your journey toward hormonal balance is a deeply personal one, rooted in the unique signals your body is sending. When you and your clinician decide on a personalized therapeutic path, often involving compounded hormones, you are placing immense trust in the idea that the preparation you receive is precisely what your body needs.

That trust is upheld by a silent, rigorous framework of regulations. Understanding this framework is the first step in truly owning your health protocol, transforming you from a passive recipient to an informed participant in your own wellness.

The preparations designed to recalibrate your internal systems fall into two primary categories, each governed by a distinct set of standards from the United States Pharmacopeia (USP). These are not arbitrary rules; they are scientifically derived protocols that acknowledge the different ways your body receives these powerful molecules.

Hormonal preparations intended for topical application, like a testosterone cream or a progesterone lotion, are classified as non-sterile. Their creation is guided by USP General Chapter <795>. This standard focuses on ensuring the purity, potency, and stability of preparations that interact with your body’s most formidable barrier ∞ the skin.

In contrast, hormonal therapies that are introduced directly into your bloodstream, such as intramuscular or subcutaneous injections of Testosterone Cypionate or growth hormone peptides, must be sterile. Their compounding is governed by the much more stringent USP General Chapter <797>.

This regulation is built on the foundational principle that anything bypassing the body’s natural defenses must be completely free of microorganisms and other contaminants. The bloodstream offers a direct pathway to every cell, and this direct access requires an absolute assurance of purity to prevent infection and maintain systemic stability. The distinction between these two standards is therefore a direct reflection of your own physiology.

The regulatory standards for compounded hormones are determined by the preparation’s route of administration, directly corresponding to the body’s own biological defenses.

The Logic of Two Paths

Think of your body’s defense systems. Your skin is a robust, multi-layered wall, equipped to handle a world that is far from sterile. A non-sterile topical hormone cream is formulated to be safe and effective when applied to this external barrier.

USP <795> ensures the cream itself is unadulterated and accurately dosed, so the correct amount of hormone is available for absorption through the skin. It mandates clean procedures, proper ingredient sourcing, and testing to prevent significant contamination or errors in concentration. The focus is on good compounding practices that produce a clean and reliable product.

Now, consider the internal environment of your body. Your bloodstream and muscle tissue are sterile environments, protected from the outside world. An injection bypasses the skin’s defenses entirely. This is where USP <797> becomes paramount. It mandates an environment and a set of procedures designed to eliminate microbial contamination at every step.

This includes the use of sterile ingredients, meticulously controlled cleanroom environments, specific garb for personnel, and rigorous testing to confirm the final preparation is sterile. The regulations for sterile compounding are fundamentally about preventing harm that could arise from introducing bacteria, fungi, or pyrogens directly into your system.

What Defines Each Standard?

The core difference in these regulations lies in their primary objective, which then dictates the required environment, processes, and testing. For non-sterile hormonal preparations under USP <795>, the objective is to produce a preparation of the correct strength and quality, minimizing the risk of errors and cross-contamination. This involves organized workspaces, qualified personnel, and reliable ingredient sources.

For sterile hormonal preparations under USP <797>, the objective is the prevention of patient harm from any form of contamination. This requires a far more complex and controlled operation, moving from a clean space to an aseptic one. The regulations detail everything from the air quality of the compounding room to the specific, validated techniques for handling sterile needles and vials.

It is a protocol designed to protect the most vulnerable internal spaces of your body, ensuring that a therapy meant to restore balance does not inadvertently introduce a new threat.

Intermediate

Advancing your understanding of hormonal health involves appreciating the meticulous processes that ensure your personalized therapies are both safe and effective. The distinction between USP <795> for non-sterile preparations and USP <797> for sterile ones moves from a general concept of ‘clean versus sterile’ to a detailed set of operational mandates.

These chapters dictate the physical environment, the actions of the compounding staff, and the lifecycle of a preparation, from formulation to its beyond-use date (BUD). Adherence to these standards is what gives clinical protocols, like Testosterone Replacement Therapy (TRT), their consistency and reliability.

How Do Environmental Controls Differ?

The physical space required for compounding is a primary differentiator between the two standards. For non-sterile hormonal creams or capsules under USP <795>, the requirement is for a designated, well-maintained area that is clean and orderly. The space must be adequate to prevent mix-ups between ingredients and preparations.

While cleanliness is essential, the air in the room does not have to meet a specific particulate count. The focus is on good housekeeping and organized workflow to ensure the final product is unadulterated and accurately potent.

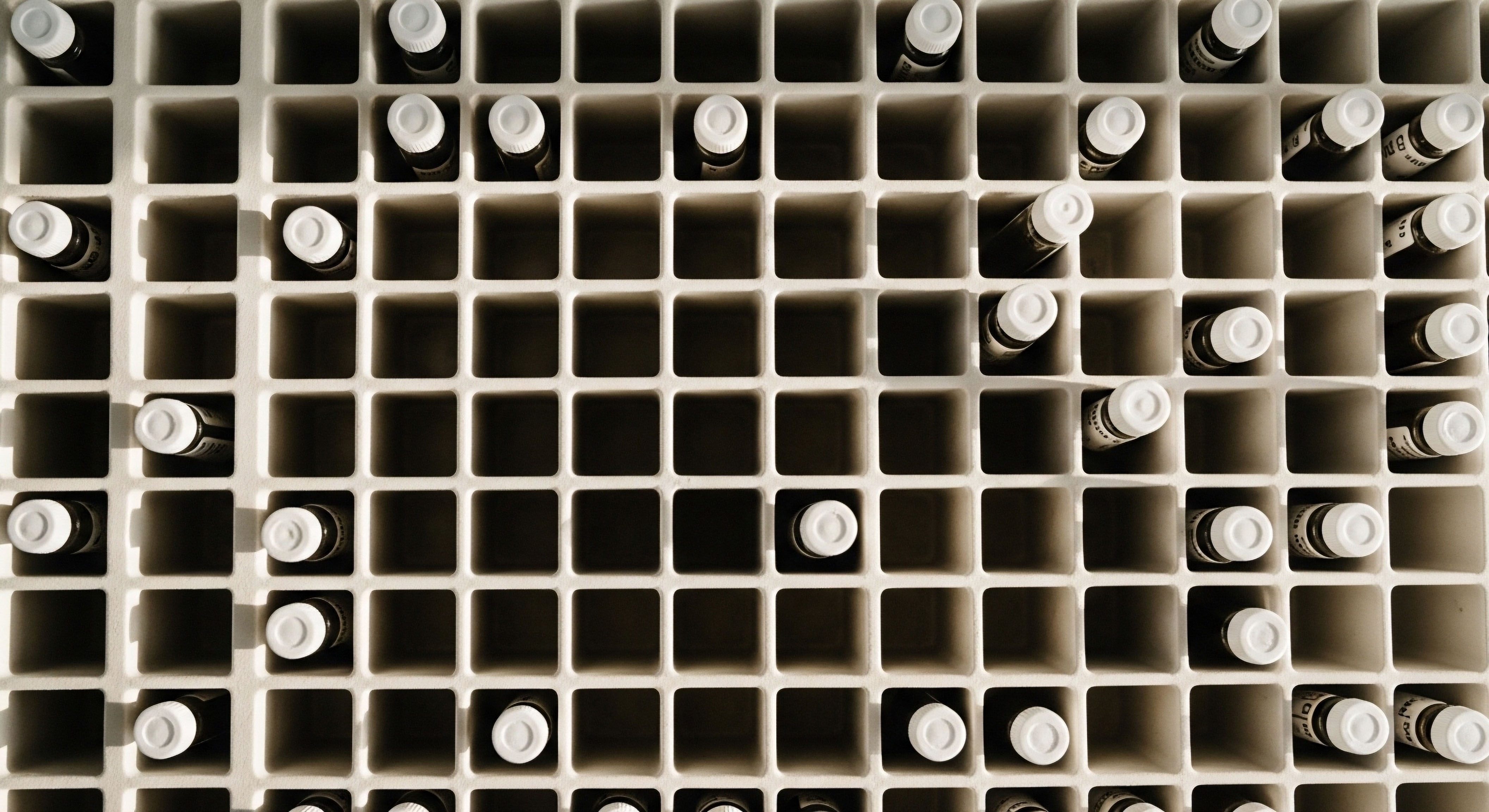

Sterile compounding under USP <797> demands a far more sophisticated and controlled environment. The core of sterile preparation occurs within a cleanroom suite, which includes an ante-room for garbing and a buffer room that houses the primary engineering control (PEC), such as a laminar airflow workbench or biological safety cabinet.

These rooms are designed to maintain specific ISO air quality classifications, meaning the number and size of airborne particles are strictly limited. This environment is supported by continuous air pressure monitoring, frequent surface testing, and a rigorous cleaning schedule to maintain a state of microbial control. This ensures that preparations like injectable Sermorelin or Testosterone Cypionate are never exposed to contaminants during the compounding process.

Personnel Training and Aseptic Technique

The human element is a critical factor in compounding, and the training requirements reflect the risks associated with each type of preparation. Under USP <795>, personnel must be qualified and trained in non-sterile compounding procedures. This includes wearing appropriate personal protective equipment (PPE) like gloves and lab coats to protect themselves from chemical exposure and to prevent contamination of the preparation. Competency is demonstrated through training and documentation.

USP <797> elevates these requirements significantly. Personnel involved in sterile compounding must undergo extensive training in aseptic technique, which is the practice of handling sterile materials in a way that prevents microbial contamination. This training is validated through rigorous testing, including media-fill tests, where a compounder manipulates microbial growth media as if it were a drug product.

The resulting sample is then incubated to see if any contamination occurred. Staff must also pass gloved fingertip and thumb sampling to prove they can garb and work without transferring microbes. This level of scrutiny is necessary because even a microscopic breach in technique could compromise the sterility of a preparation intended for injection.

The stringency of environmental and personnel requirements under USP standards directly correlates with the level of risk to the patient’s internal biological systems.

The table below outlines some of the key operational distinctions between the two standards, illustrating how the requirements scale with the risk level of the final preparation.

| Operational Aspect | USP <795> (Non-Sterile Hormones) | USP <797> (Sterile Hormones) |

|---|---|---|

| Compounding Environment |

A designated, clean, and well-organized area. No specific air quality classification required. |

An ISO-classified cleanroom suite with positive pressure differentials and controlled airflow. |

| Primary Goal |

Ensure potency, accuracy, and purity; minimize errors and cross-contamination. |

Ensure sterility by preventing microbial, chemical, and physical contamination. |

| Personnel Garb |

Gloves and lab coat are standard. Additional garb is based on the specific chemicals being handled. |

Full sterile garb including hair cover, mask, shoe covers, and sterile gown and gloves. |

| Quality Assurance |

Focus on formulation accuracy, proper labeling, and adherence to beyond-use dates (BUDs) based on water content and preservatives. |

Includes environmental monitoring (air/surface sampling), media-fill testing, and sterility testing for high-risk preparations. |

| Example Preparations |

Topical Testosterone Cream, Progesterone Capsules, Anastrozole Tablets. |

Injectable Testosterone Cypionate, Gonadorelin, Ipamorelin/CJC-1295 Peptides. |

Beyond-Use Dating and Stability

Another critical difference lies in establishing the beyond-use date (BUD) for a preparation. The BUD is the date after which a compounded preparation should not be used. For non-sterile preparations under USP <795>, BUDs are determined primarily by the stability of the formulation, particularly its water content. For example, a non-preserved aqueous formulation has a much shorter BUD (14 days refrigerated) than a nonaqueous formulation like a petrolatum-based ointment (90 days). This is because water supports microbial growth.

For sterile preparations, the BUD is determined by both the chemical stability of the drug and the potential for microbial contamination after compounding. USP <797> defines BUDs based on the risk level of the compounding process (low, medium, or high) and the storage conditions (room temperature, refrigerated, or frozen).

A low-risk sterile preparation, such as drawing a single dose of testosterone from a sterile vial into a syringe within a cleanroom, will have a specific BUD that assumes its sterility is maintained for that period. These rigorously defined BUDs are essential for ensuring that a product remains safe and stable throughout its intended course of use.

Academic

A sophisticated application of hormonal therapy requires an appreciation of the molecular and microbiological risks that pharmacy compounding regulations are designed to mitigate. The standards of USP <795> and USP <797> represent a clinical-grade risk management strategy, grounded in pharmacology, microbiology, and physiology.

The differences in these regulations are a direct response to the body’s differential tolerance for contamination at its external versus internal interfaces. Examining these regulations from a systems-biology perspective reveals their profound impact on the safety and efficacy of personalized endocrine support protocols.

What Is the Consequence of Contamination in Sterile Preparations?

The mandates of USP <797> are designed to prevent the introduction of two primary threats into the systemic circulation ∞ viable microorganisms and pyrogenic molecules. While the danger of a bacterial or fungal infection from a contaminated injection is self-evident, the threat of pyrogens, particularly endotoxins, is more subtle and equally disruptive to homeostatic balance.

Endotoxins are lipopolysaccharides (LPS) that are part of the outer membrane of Gram-negative bacteria. Even after bacteria are killed by sterilization, these molecules can remain and, if injected, can trigger a potent inflammatory cascade.

When endotoxins enter the bloodstream, they are recognized by the innate immune system, leading to the release of pro-inflammatory cytokines like TNF-α, IL-1β, and IL-6. This systemic inflammation can have devastating consequences for a patient on a hormonal optimization protocol.

For example, this inflammatory state can activate the hypothalamic-pituitary-adrenal (HPA) axis, leading to elevated cortisol levels. Chronically elevated cortisol can counteract the intended benefits of testosterone therapy, promoting muscle catabolism and insulin resistance.

It creates a state of physiological noise that can disrupt the delicate signaling of the hypothalamic-pituitary-gonadal (HPG) axis, potentially blunting the efficacy of therapies like Gonadorelin or TRT. Therefore, the meticulous aseptic techniques and environmental controls of USP <797> are a prerequisite for achieving the intended physiological outcome of sterile hormonal therapies.

Potency and Bioavailability in Non-Sterile Formulations

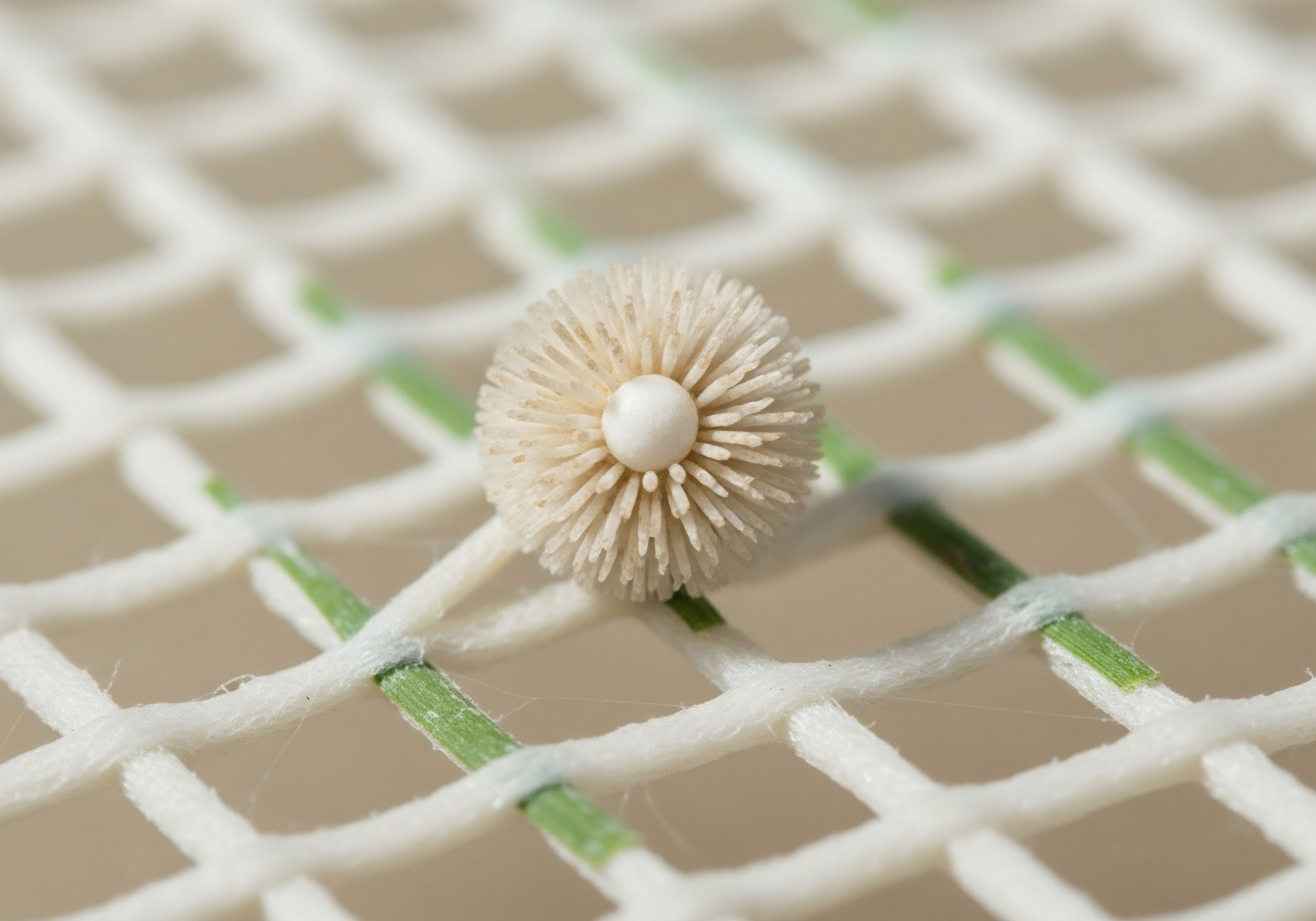

For non-sterile preparations governed by USP <795>, the primary risk shifts from sterility to the physicochemical properties of the preparation itself, namely potency and homogeneity. For a transdermal hormone cream, the therapeutic effect depends on the consistent release of the active pharmaceutical ingredient (API) from its vehicle and its subsequent absorption through the skin. USP <795> mandates documented procedures and master formulation records to ensure that every batch of a cream is prepared identically.

Inconsistent mixing can create “hot spots” or areas of low concentration within the cream. This variability introduces significant clinical risk. A patient could apply cream from a low-potency area of the container for days, experiencing a return of symptoms, only to then encounter a high-potency section that delivers a supratherapeutic dose.

In male TRT, this could lead to a sudden spike in estradiol levels due to increased aromatase activity, causing unwanted side effects. In female therapy, it could disrupt the carefully balanced ratio of testosterone to other hormones. The regulations in USP <795> regarding process controls, ingredient verification, and documentation are designed to ensure that the 100mg of testosterone prescribed is the 100mg delivered, dose after dose.

The regulatory divide between sterile and non-sterile compounding reflects a deep understanding of risk, targeting microbial threats for injectables and physicochemical consistency for topicals.

The risk levels defined within USP <797> provide a granular framework for matching procedural rigor to the probability of contamination, a concept that is central to academic risk management.

| USP <797> Risk Level | Description of Process | Primary Contamination Risk | Required Controls |

|---|---|---|---|

| Low-Risk |

Compounding with only sterile ingredients and equipment, involving simple transfers and manipulations within an ISO 5 environment. |

Touch contamination from improper aseptic technique. |

PEC in an ISO 7 buffer room; personnel trained in aseptic technique; media-fill testing annually. |

| Medium-Risk |

More complex manipulations, such as combining multiple sterile products or preparing a batch for multiple patients. |

Increased risk of touch contamination due to longer duration and complexity of the compounding process. |

Same as low-risk, with more comprehensive process validation and more frequent personnel testing. |

| High-Risk |

Using non-sterile ingredients or exposing sterile ingredients to an environment worse than ISO 5 before terminal sterilization. |

Presence of viable microorganisms and endotoxins in the final preparation before sterilization. |

All medium-risk controls plus the requirement for the final preparation to be terminally sterilized and tested for sterility and pyrogens. |

Why Is a Designated Person so Important for Compliance?

Recent updates to both USP <795> and <797> introduced the requirement for a single “designated person” to be responsible for the oversight of all compounding activities. From an academic and quality systems perspective, this is a critical development. This role centralizes accountability, ensuring that there is one individual with the authority and responsibility to develop, implement, and enforce all compounding procedures.

This person is responsible for validating that personnel are adequately trained, that environmental controls are functioning, and that documentation is complete and accurate. For a clinic managing complex protocols involving both sterile peptides and non-sterile creams, this designated person ensures that both sets of standards are met with equal rigor, protecting patients from the distinct risks associated with each type of preparation.

References

- United States Pharmacopeial Convention. General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP-NF). Rockville, MD ∞ United States Pharmacopeial Convention; 2023.

- United States Pharmacopeial Convention. General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP-NF). Rockville, MD ∞ United States Pharmacopeial Convention; 2023.

- Kastango, Eric S. and James T. Wagner. “USP chapter 797 ∞ A 10-year retrospective.” International Journal of Pharmaceutical Compounding, vol. 18, no. 1, 2014, pp. 24-30.

- National Association of Boards of Pharmacy. “Sterile Compounding Pharmacies | USP 795 & 797.” NABP, 4 Dec. 2023.

- Allen, Loyd V. Jr. “Basics of Compounding ∞ Nonsterile Compounding.” International Journal of Pharmaceutical Compounding, vol. 17, no. 3, 2013, pp. 223-229.

- Gabay, Michael. “Revisions to USP Chapters <795> and <797>.” Hospital Pharmacy, vol. 54, no. 6, 2019, pp. 363-364.

- McElhiney, Linda F. “Aseptic Technique and Compounding of Sterile Preparations.” Compounding for Veterinarians, 2018, pp. 11-23.

Reflection

You have now seen the intricate framework that stands behind every personalized hormone prescription. This knowledge shifts your position. You are now equipped to ask more precise questions about your therapies, to understand the profound importance of the pharmacy you choose, and to appreciate that the path to reclaiming your vitality is paved with both clinical science and rigorous standards.

Your hormonal journey is a partnership between you, your clinician, and the compounding professionals who translate your prescription into a physical reality. The true potential of this journey is unlocked when you can see the full picture, understanding that the silent work of regulation is what allows the science of hormonal health to become a reliable part of your personal story.