Fundamentals

The decision to begin a personalized hormonal protocol represents a significant step in taking control of your biological narrative. You arrive at this point because you have listened to your body. The fatigue, the changes in mood or metabolism, the subtle or significant shifts in your sense of vitality ∞ these are all data points.

They are your lived experience, and they are valid. When a standard therapeutic option does not fit your specific physiological requirements, you and your clinician may determine that a compounded preparation is the most precise path forward. This brings you to the door of a compounding pharmacy, and with it, a very direct question ∞ how can you be certain that the preparation you receive is exactly what your body needs, in the precise dosage and form required?

Understanding the answer begins with recognizing what a compounding pharmacy Meaning ∞ A compounding pharmacy specializes in preparing personalized medications for individual patients when commercially available drug formulations are unsuitable. does. It is a specialized facility where a licensed pharmacist, upon receiving a prescription from your practitioner, combines, mixes, or alters ingredients to create a medication tailored to your individual needs.

This could mean formulating a testosterone cream at a specific concentration unavailable commercially, creating a bioidentical progesterone capsule without a filler you are allergic to, or combining multiple hormones into a single application. The process is one of precision and personalization, moving beyond the one-size-fits-all model of mass-produced pharmaceuticals. Your body has a unique set of requirements, and the purpose of compounding is to meet those requirements with exacting specificity.

The quality of that final preparation is a direct extension of a deeply regulated and controlled process. It is a system of checks and balances designed to ensure that the medication in your hands is safe, potent, and pure. This assurance is built upon a foundation of established standards, rigorous procedures, and verifiable results.

It is a scientific and professional obligation to translate your prescription into a reliable therapeutic tool. Your trust in this process is paramount, and that trust is earned through a demonstrable commitment to quality at every single stage, from the moment raw ingredients arrive at the pharmacy to the final verification of the preparation made just for you.

The Building Blocks of Your Preparation

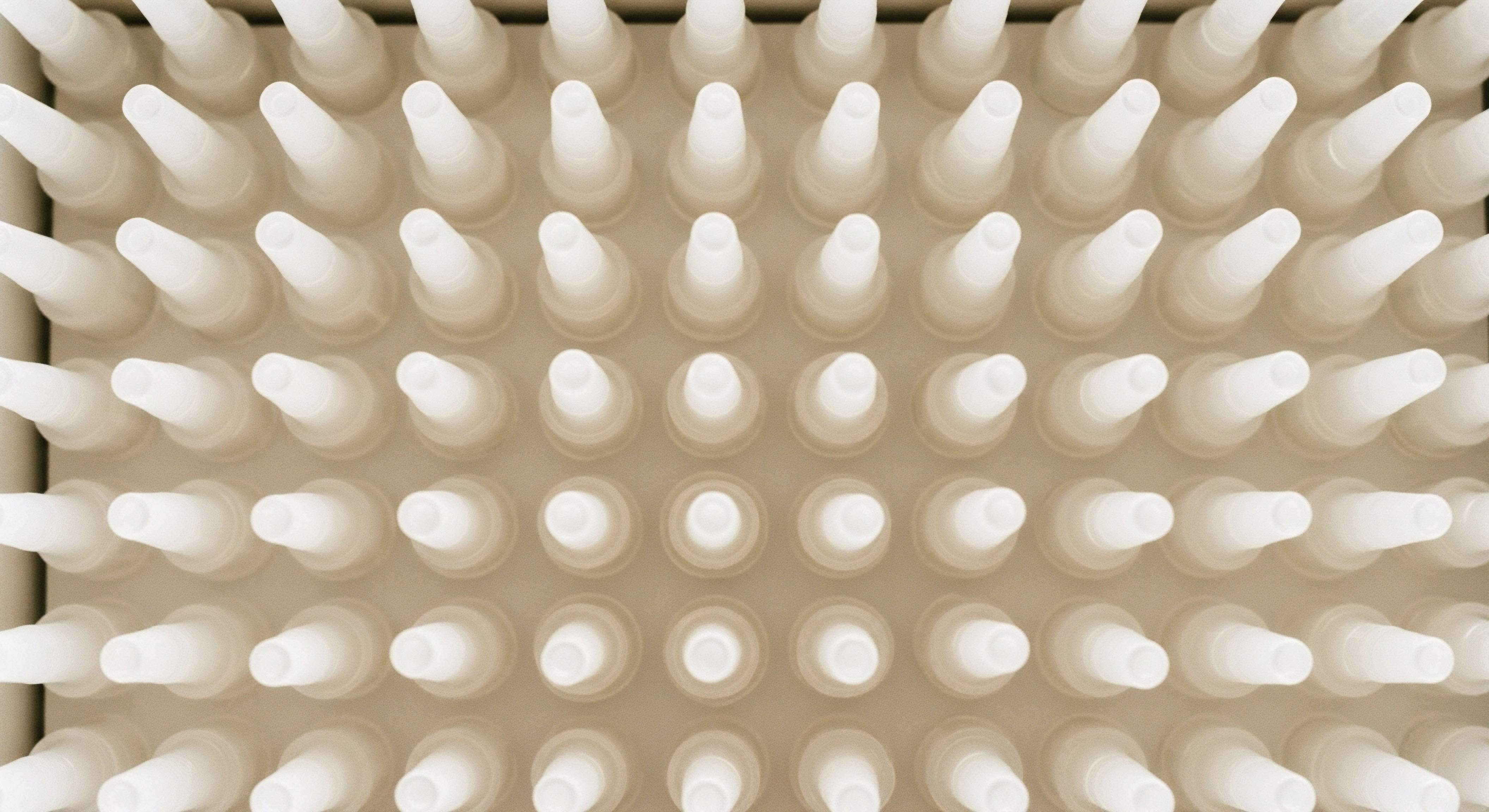

Any hormonal preparation contains two primary types of components ∞ the Active Pharmaceutical Ingredient Meaning ∞ The Active Pharmaceutical Ingredient, often abbreviated as API, refers to the biologically active component within a drug product responsible for its intended therapeutic effect. (API) and the excipients. The API is the hormone itself ∞ the testosterone, estradiol, or progesterone that will interact with your body’s cellular receptors to produce a physiological effect. The quality control for your medication begins with the quality of this raw material.

Reputable compounding pharmacies Meaning ∞ Compounding pharmacies are specialized pharmaceutical establishments that prepare custom medications for individual patients based on a licensed prescriber’s order. source their APIs from FDA-registered suppliers. Each batch of API arrives with a document called a Certificate of Analysis Meaning ∞ A Certificate of Analysis, often abbreviated as CoA, represents an official document issued by a manufacturer or third-party laboratory, detailing the specific test results and quality control parameters for a particular batch of a product. (CofA). This document is a detailed report from the manufacturer that confirms the identity, purity, and strength of the chemical. It is the pharmacy’s first line of defense, a guarantee that the foundational element of your medication meets established pharmaceutical-grade standards before it is even unpacked.

Excipients are the other ingredients in your preparation. These are the carriers, binders, and fillers that create the final form of the medication, such as a cream, gel, capsule, or oil. In a transdermal cream, for instance, the excipients make up the base that allows the hormone to be absorbed effectively through the skin.

While they are considered “inactive” in a therapeutic sense, their quality is just as important. The choice of base can affect the stability of the hormone, its absorption rate, and the potential for skin irritation. Quality control Meaning ∞ Quality Control, in a clinical and scientific context, denotes the systematic processes implemented to ensure that products, services, or data consistently meet predefined standards of excellence and reliability. extends to these components as well, ensuring they are pure, stable, and compatible with the API. For individuals with sensitivities or allergies, the ability to select specific, high-quality excipients is a core benefit of the compounding process.

A compounding pharmacy’s first commitment to quality is the verification of every raw ingredient through a Certificate of Analysis, ensuring purity from the start.

Why Is the Process so Important?

Imagine two chefs preparing the same recipe. One follows the instructions meticulously, using precisely measured ingredients and calibrated ovens. The other estimates measurements and is less attentive to timing. The results will be vastly different. The same principle applies with even greater consequence in pharmaceutical compounding.

The process itself is a critical control point. To ensure consistency and safety, compounding pharmacies operate under a comprehensive set of rules known as Standard Operating Procedures (SOPs). These are detailed, written instructions that define every single action taken in the laboratory.

There are SOPs for how personnel must gown and wash their hands before entering the compounding area. There are SOPs for how laboratory equipment is cleaned, calibrated, and maintained. There are SOPs for how each type of preparation is mixed, how long it is blended to ensure uniform distribution of the hormone, and how it is packaged.

This level of procedural detail removes guesswork and minimizes the potential for human error. It ensures that whether your prescription is filled on a Monday morning or a Friday afternoon, the process is identical and the quality is consistent. This procedural rigor is the architecture of quality, building a safe and reliable product through a series of deliberate, repeatable, and documented actions.

Intermediate

For those familiar with the basics of hormonal health, the conversation about quality control in compounding pharmacies advances to the specific regulatory frameworks that govern their operations. Your confidence in a compounded hormonal preparation is directly tied to the pharmacy’s adherence to a set of comprehensive standards published by the United States Pharmacopeia The legality of compounding peptides for wellness in the U.S. (USP).

The USP is a non-profit, scientific organization that sets federally recognized public standards for medicines. Compliance with these standards is a direct measure of a pharmacy’s commitment to providing safe and effective preparations. Two chapters are particularly central to the compounding of hormones ∞ USP General Chapter for Nonsterile Preparations and USP General Chapter for Sterile Preparations.

These chapters provide the detailed blueprint for quality. They are not merely suggestions; in many states, they are legally enforceable by state boards of pharmacy. They dictate the conditions under which your medications are made, the training required for the people who make them, and the documentation needed to prove compliance.

Understanding the distinction between these two chapters is essential, as the type of hormonal preparation you are prescribed determines which set of rules applies. This distinction has significant implications for the level of environmental control and procedural rigor required.

USP 795 the Standard for Nonsterile Preparations

Most compounded hormonal therapies, such as topical creams, gels, capsules, and oral solutions, fall under the category of nonsterile preparations. Their production is governed by USP Chapter . The core objective of this chapter is to provide practices and guidelines that prevent patient harm caused by microbial contamination, excessive dosage, or the presence of unwanted chemical or physical contaminants. It establishes the minimum standards for creating a high-quality nonsterile product.

Key requirements under USP include:

- Personnel Training ∞ All personnel involved in compounding must be trained and qualified. Their competency must be regularly evaluated and documented. This includes understanding the chemical properties of the hormones and excipients they are handling.

- Designated Compounding Area ∞ Preparations must be made in an area specifically designated for nonsterile compounding. This space must be kept clean, orderly, and at an appropriate temperature and humidity to ensure the stability of the ingredients.

- Ingredient Sourcing and Storage ∞ As discussed in the fundamentals, all ingredients must be sourced from reliable suppliers and comply with USP or National Formulary (NF) monographs where applicable. They must be stored appropriately to prevent degradation.

- Documentation and Record-Keeping ∞ A master formulation record is created for each unique preparation, acting as the recipe. A compounding record is then completed for every prescription filled, documenting the specific ingredients, lot numbers, quantities, and personnel involved. This creates a complete audit trail.

- Beyond-Use Dating (BUD) ∞ The chapter provides guidance on assigning a BUD, which is the date after which a compounded preparation should not be used. This is determined based on the type of formulation and its water content, which influences its stability and susceptibility to microbial growth.

USP Chapter provides the essential framework for ensuring the quality and safety of common hormonal preparations like creams and capsules.

What Are the Rules for Sterile Hormonal Preparations?

When a hormonal preparation is intended for injection, such as Testosterone Cypionate, or for administration into a sterile body cavity, it must be prepared under the much more stringent conditions outlined in USP Chapter . The risk of patient harm from a contaminated sterile product, such as a bloodstream infection, is significantly higher. Consequently, the controls required are far more extensive. This chapter focuses on preventing harm from microbial contamination, bacterial endotoxins, and other potential contaminants associated with injectable drugs.

The core of USP is the requirement for a highly controlled environment. Sterile compounding Meaning ∞ Sterile compounding involves preparing pharmaceutical products entirely free from viable microorganisms and pyrogens. must occur within a “cleanroom,” which is a suite of rooms with specific engineering controls to maintain extremely low levels of airborne particulates and microorganisms. This includes:

- Primary Engineering Controls (PECs) ∞ A device like a laminar airflow workbench or biological safety cabinet that provides an ISO Class 5 environment, which is an extremely clean workspace where the actual sterile manipulations are performed.

- Secondary Engineering Controls (SECs) ∞ The buffer room that houses the PEC, and an adjacent ante-room. These rooms have specific air pressure differentials, HEPA filtration systems, and temperature and humidity controls to maintain their cleanliness classification.

- Gowning and Aseptic Technique ∞ Personnel must follow a strict garbing procedure with sterile gloves, gowns, hair covers, and masks. They must also master aseptic technique, a set of specific manipulations that prevent touch contamination of sterile ingredients and supplies. Their technique is regularly tested through processes like media-fill tests.

The table below summarizes the fundamental differences in the requirements, illustrating why the preparation of an injectable hormone requires a completely different level of infrastructure and procedural discipline.

| Feature | USP (Nonsterile) | USP (Sterile) |

|---|---|---|

| Common Preparations | Topical creams, gels, oral capsules, solutions | Injections, infusions, ophthalmic drops |

| Compounding Environment | A designated, clean, and orderly area | An ISO-classified cleanroom suite with positive/negative air pressure |

| Primary Risk | Incorrect dosage, cross-contamination, microbial growth over time | Direct introduction of microbes or endotoxins into the bloodstream |

| Personnel Garb | Clean lab coat, gloves | Sterile gown, gloves, hair/shoe covers, face mask |

| Required Testing | Procedural checks, visual inspection | Aseptic technique validation (media-fill tests), environmental monitoring |

Academic

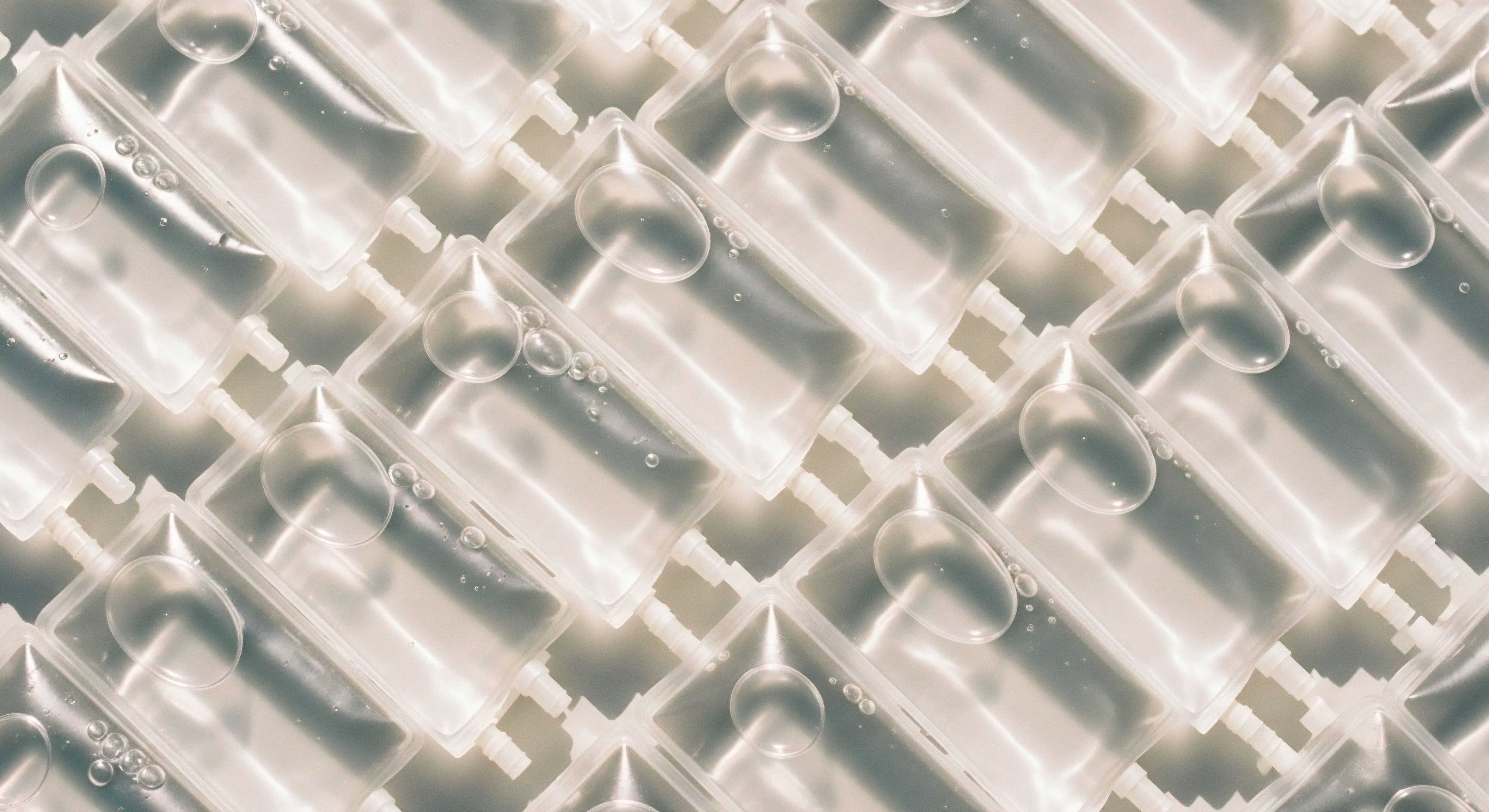

From an academic and clinical science perspective, the quality control systems within a compounding pharmacy culminate in a single, vital objective ∞ analytical verification. While adherence to USP standards and meticulous SOPs builds quality into the process, the ultimate confirmation of a hormonal preparation’s potency and purity comes from quantitative chemical analysis.

This is where the pharmacy’s work is submitted to the objective scrutiny of analytical science. For you, the individual whose physiology will be influenced by this preparation, this step provides the highest level of assurance that the medication contains the precise amount of the active hormone prescribed by your clinician.

The primary analytical technique used for this purpose is High-Performance Liquid Chromatography, or HPLC. This sophisticated instrumentation allows a pharmacist or analytical chemist to separate, identify, and quantify each component in a complex mixture with a high degree of precision.

When a sample of your compounded testosterone cream or progesterone capsule is tested, HPLC can definitively answer the most important question ∞ is the concentration of the hormone within the acceptable pharmaceutical limits of the prescribed dose? This is the gold standard for potency testing Meaning ∞ Potency testing refers to the analytical process of quantifying the active pharmaceutical ingredient within a medication to ascertain its precise strength and biological activity. in the compounding industry.

How Does High Performance Liquid Chromatography Work?

To understand the power of HPLC, one must visualize the process at a molecular level. The technique separates components of a mixture by passing it through a column packed with a special solid material (the stationary phase) while a liquid solvent (the mobile phase) is pumped through under high pressure.

Different molecules in the sample will travel through the column at different speeds based on their chemical properties, such as their size and polarity. This differential migration causes the components to separate.

In the context of hormonal preparations:

- Sample Preparation ∞ A precise amount of the compounded medication is dissolved in a suitable solvent to extract the hormone and other ingredients into a liquid solution.

- Injection and Separation ∞ A small, measured volume of this solution is injected into the HPLC system. As the mobile phase carries the sample into the column, the hormone (e.g. estradiol) will interact with the stationary phase differently than the excipients from the cream base. This causes the estradiol to exit the column at a specific, predictable time, known as its retention time.

- Detection and Quantification ∞ As each component exits the column, it passes through a detector. For hormones, a UV-Vis detector is common, as the steroid structure absorbs ultraviolet light. The detector generates a signal proportional to the concentration of the substance passing through it. This creates a chromatogram, which is a graph showing peaks that correspond to each separated component. The area under the peak for the hormone is directly proportional to its concentration in the sample.

By comparing the peak area of the sample to the peak area of a known, certified reference standard of that same hormone, the exact concentration in the compounded preparation can be calculated. A reputable pharmacy will have established acceptance criteria, typically requiring the measured potency to be within ±10% of the prescribed amount, a common standard in the pharmaceutical industry.

What Is the Role of Third Party Testing?

While some advanced compounding pharmacies have in-house HPLC capabilities for routine verification, the highest standard of quality assurance involves sending samples to an independent, third-party analytical laboratory. This practice removes any potential for internal bias and provides an objective, external validation of the pharmacy’s compounding accuracy.

Studies have shown that pharmacies participating in such external testing programs demonstrate high levels of accuracy and consistency. When a pharmacy commits to this level of scrutiny, it demonstrates profound confidence in its processes and a deep commitment to patient safety. It is a tangible investment in trust.

The use of High-Performance Liquid Chromatography (HPLC) provides objective, quantitative proof of a hormonal preparation’s potency and purity.

Beyond potency, analytical testing can also screen for potential issues. The table below outlines some key quality attributes for a hormonal cream and the methods used to ensure they are met. This illustrates the multi-faceted nature of quality verification, moving beyond just the active ingredient to ensure the entire product is sound.

| Quality Attribute | Purpose of Test | Primary Analytical Method |

|---|---|---|

| Potency | To confirm the concentration of the active hormone (e.g. Testosterone) matches the prescription. | High-Performance Liquid Chromatography (HPLC) |

| Purity/Degradation | To ensure the active hormone has not broken down into other substances and to identify any impurities from the raw material. | HPLC with mass spectrometry (LC-MS) for identification of unknown peaks. |

| Content Uniformity | To verify that the hormone is evenly distributed throughout the cream base. | HPLC testing of samples taken from different locations in the container. |

| Microbial Limits | To ensure the preparation is free from harmful levels of bacteria, yeast, and mold. | Microbiological culture testing according to USP and . |

This level of analytical rigor is the final, critical link in the quality control chain. It connects the physician’s prescription, the pharmacist’s formulation, and your body’s physiological needs with objective, scientific data. It verifies that the personalized medicine you receive is not only conceptually correct but also chemically precise. This is the ultimate expression of the “Clinical Translator” ethos ∞ transforming a therapeutic plan into a validated, reliable product that supports your personal health objectives.

References

- Thomas Haraldsen, Jason. “The standardization of nonsterile compounding ∞ a study in quality control and assessment for hormone compounding.” International Journal of Pharmaceutical Compounding, 2015.

- National Academies of Sciences, Engineering, and Medicine. “The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence.” National Academies Press, 2020.

- “USP Quality Standards for Compounding.” United States Pharmacopeia, 2013.

- “USP General Chapter Pharmaceutical Compounding ∞ Nonsterile Preparations.” United States Pharmacopeia, 2014.

- “Complementary Compounding Services. Compounding Pharmacy Quality Control.” Complementary Compounding Services, 2023.

- “USP 797 and USP 795 ∞ Creating and Managing a State of Control.” Wolters Kluwer, 2023.

- Schlesser, Michael. “High-performance liquid chromatography for hormone assay.” Methods in Molecular Biology, 1988.

- Microtrace. “Hormone Assay Methods by HPLC.” Microsolv Technology Corporation, 2012.

- “High-Performance Liquid Chromatography for Hormone Assay.” Springer Nature Experiments, 1988.

- Zawadzka, Paulina, et al. “Development of an HPLC-FLD Method for Estradiol and Metabolites ∞ Application of Solid-Phase Microextraction.” Molecules, vol. 28, no. 23, 2023.

Reflection

You began this inquiry seeking assurance. You sought to understand the systems that stand behind the medication designed specifically for you. The layers of quality control, from the sourcing of a single raw ingredient to the sophisticated light of an HPLC detector, are all components of a single, unified purpose ∞ to make your therapeutic protocol both safe and effective.

The knowledge of these processes ∞ the SOPs, the USP chapters, the analytical tests ∞ is now part of your toolkit. It allows you to ask informed questions and to engage with your healthcare providers as a partner in your own wellness.

This understanding is the foundation. The next step in your path involves applying this knowledge to your own choices and your own body’s response. The data from your lab results and the way you feel are the ultimate arbiters of your protocol’s success.

The quality control of a compounding pharmacy ensures that the tool you are using is precisely what it claims to be. How you and your clinician use that tool to recalibrate your system and restore your vitality is the deeply personal and powerful work that lies ahead. The science of quality makes the art of personalized medicine possible.