Fundamentals

Your journey toward hormonal balance often begins with a feeling of being misunderstood. The standard, one-size-fits-all approach to medicine may not fully address the unique signals your body is sending. You experience symptoms, you review lab results with your clinician, and you arrive at a therapeutic plan that is yours alone.

This is where the world of pharmaceutical compounding enters your story. It represents a path where medicine is formulated specifically for your physiological requirements, a validation of your individual biology. The question of how these specialized pharmacies ensure the purity of your medication is central to the trust you place in this process. It speaks to the very foundation of personalized medicine, where safety and precision are the essential components of your care.

A compounded medication is created from its fundamental components, the active pharmaceutical ingredients (APIs), combined with other necessary elements to create a dosage form tailored to you. This process is a world away from the mass production lines of large drug manufacturers. It is a precise craft, performed by a licensed pharmacist for a specific patient.

The assurance of its quality rests on a tripod of rigorous controls that together create a shield of safety around your personalized therapy. Understanding these pillars empowers you to be an informed participant in your own wellness protocol.

The Purity of the Source Ingredient

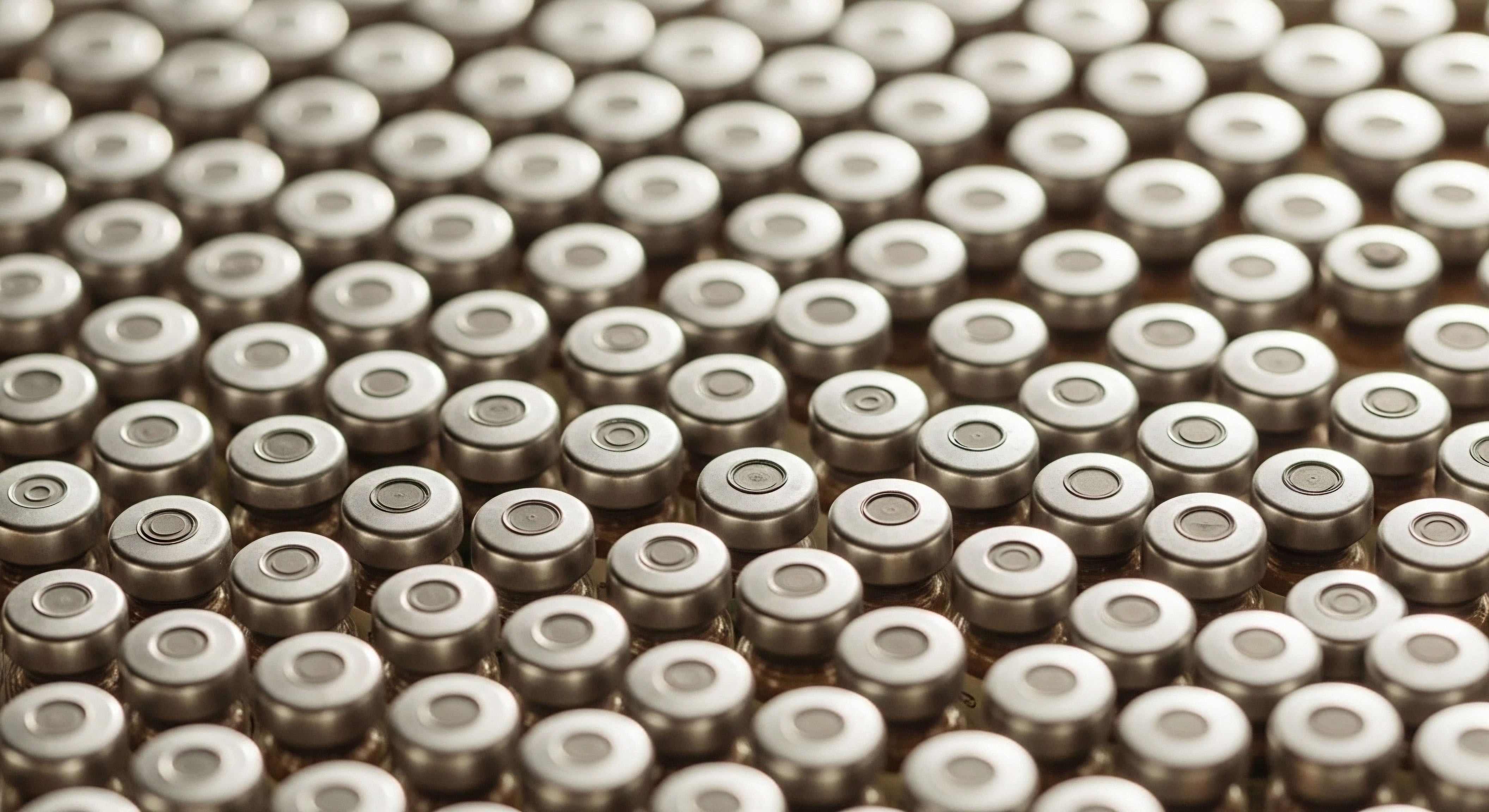

Every effective therapy begins with its foundational active ingredient. For your compounded hormone preparation, whether it is Testosterone Cypionate for weekly injections or a topical Estriol cream, the process starts with a pure, potent powder. Compounding pharmacies must procure these APIs from reputable suppliers who are registered and inspected by regulatory bodies like the Food and Drug Administration (FDA).

Each batch of an API arrives with a Certificate of Analysis (CoA), a document that acts as its chemical passport. This CoA verifies the ingredient’s identity, strength, and purity, confirming it is free from contaminants. This initial step is a critical checkpoint, ensuring that the very building block of your medication meets exacting scientific standards before the compounding process even begins.

The Integrity of the Compounding Process

With a verified ingredient in hand, the pharmacist turns to the formulation process. This is a sequence of precise, repeatable steps designed to create your medication safely and accurately. Every unique formulation has a corresponding Master Formulation Record (MFR).

This document is the specific recipe, detailing everything from the exact quantities of each ingredient to the specific equipment to be used, the step-by-step mixing instructions, and the final packaging and labeling requirements. For a non-sterile compound like a progesterone capsule, the process involves meticulous weighing and blending.

For a sterile preparation like an injectable peptide, the process is far more complex, occurring within a highly controlled environment to prevent any microbial contamination. Adherence to this MFR ensures that the medication you receive today is identical in its composition and quality to the one you will receive next month, providing a consistent and reliable therapeutic effect.

The Master Formulation Record is the blueprint for your personalized medication, ensuring consistency and accuracy in every prescription filled.

The Control of the Compounding Environment

The physical space where your medication is created is the final pillar of safety. The requirements for this environment are dictated by the type of medication being prepared. Oral and topical preparations are governed by standards for non-sterile compounding, which mandate a clean, well-maintained area with procedures to prevent cross-contamination between different drug substances.

The standards for sterile compounding, which applies to therapies like injections or eye drops, are significantly more stringent. These medications must be prepared in a specially engineered cleanroom. This room uses sophisticated air filtration systems (HEPA filters) to remove particulates and microorganisms, and maintains specific pressure gradients to prevent contaminated air from entering.

Personnel must undergo extensive training in aseptic techniques and wear sterile garb, including gowns, gloves, and masks, to ensure they do not introduce contaminants into the product. This controlled environment is a physical manifestation of the pharmacy’s commitment to patient safety, protecting you from the risk of infection and ensuring the final product is sterile.

These foundational principles are codified by the United States Pharmacopeia (USP), a scientific organization that sets standards for the quality and purity of medicines. By following these established guidelines for ingredients, processes, and environment, a compounding pharmacy transforms a personalized prescription into a safe, pure, and effective therapy, becoming a trusted partner in your health journey.

Intermediate

As you become more engaged with your personalized wellness protocol, your understanding of the systems that protect you deepens. The foundational principles of purity, process, and environment are upheld by a detailed regulatory and standards-based framework.

This framework is designed to manage risk and ensure that your compounded medications, from topical hormone creams to injectable peptides, are prepared with the highest degree of scientific rigor. Two primary forces shape this landscape ∞ the legally enforceable standards set by the United States Pharmacopeia (USP) and the regulatory oversight of the Food and Drug Administration (FDA), which distinguishes between different types of compounding pharmacies based on their scale and function.

The United States Pharmacopeia Compounding Compendium

The USP creates the essential playbook for compounding pharmacies. These standards are not mere suggestions; they are integrated into the regulations of most state boards of pharmacy, making them the effective law of compounding practice. Three specific chapters form the core of this compendium, each addressing a different aspect of medication preparation.

- USP General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations ∞ This chapter governs the compounding of medications that are administered orally, topically, or rectally, such as testosterone gels, progesterone capsules, or oral anastrozole tablets. It establishes the minimum requirements for the compounding environment, personnel training, ingredient sourcing, documentation (Master Formulation Records and Compounding Records), and assigning beyond-use dates (BUDs). The focus is on ensuring the final preparation has the correct potency and is free from errors and contamination.

- USP General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations ∞ This is the critical standard for injectable therapies, including Testosterone Cypionate, Gonadorelin, and peptide protocols like Sermorelin or CJC-1295/Ipamorelin. Its primary objective is to prevent patient harm from microbial contamination, excessive bacterial endotoxins, and variability in strength. The chapter details requirements for facility design (cleanrooms and buffer areas), environmental monitoring (air and surface sampling), personnel garbing and aseptic technique validation (media-fill testing), and the assignment of BUDs based on the preparation’s risk level. Preparations are classified into categories based on the complexity and sterility of the starting components, with more complex procedures requiring stricter controls.

- USP General Chapter <800> Hazardous Drugs ∞ Handling in Healthcare Settings ∞ Many of the hormones used in optimization protocols, such as testosterone and estrogens, are classified as hazardous drugs due to their potential to cause reproductive or other health issues in personnel who handle them without protection. This chapter provides standards for protecting healthcare workers and the environment from exposure. It mandates specific engineering controls (e.g. negative pressure rooms), personal protective equipment (PPE), and strict procedures for handling, compounding, and disposing of these substances. Compliance with USP <800> is an additional layer of safety that runs parallel to USP <795> and <797>.

What Is the Difference between 503a and 503b Pharmacies?

The FDA further segments the world of compounding into two distinct categories, defined by sections 503A and 503B of the Federal Food, Drug, and Cosmetic Act. Understanding which type of pharmacy prepares your medication provides insight into the regulatory standards it must meet. Your clinician makes a conscious choice when deciding where to source your therapy, and this distinction is a key part of that decision-making process.

A 503A compounding pharmacy is what most people picture as a traditional pharmacy that compounds. These facilities prepare medications based on the receipt of a valid, patient-specific prescription. They are primarily regulated by state boards of pharmacy, which typically mandate compliance with USP standards.

Because they produce customized medications for individuals, they are exempt from certain federal requirements that apply to large-scale drug manufacturers, such as the FDA’s new drug approval process and Current Good Manufacturing Practices (CGMP). This model allows for the highest degree of personalization for therapies tailored to your specific hormonal needs.

A 503B outsourcing facility operates on a larger scale. These facilities can manufacture large batches of compounded drugs with or without patient-specific prescriptions, which are then sold to healthcare providers (like your doctor’s office) for office use.

Because they function more like a manufacturer, 503B facilities must register with the FDA and are held to the more stringent federal CGMP standards. These standards involve a much more rigorous system of quality control, including process validation for every formulation and extensive testing of final products before they are released. While this may offer less individualized formulation, it provides a high level of uniformity and documented quality for standard-protocol medications that a clinic may use for many patients.

The distinction between 503A and 503B pharmacies defines the regulatory pathway, balancing customized patient care with the rigorous controls of large-scale production.

The following table illustrates the key operational and regulatory differences between these two types of facilities.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Function | Fills patient-specific prescriptions. | Produces large batches for office use and distribution to healthcare facilities. |

| Prescription Requirement | Required for each compounded preparation. | Can produce without patient-specific prescriptions. |

| Primary Regulatory Oversight | State Boards of Pharmacy. | Food and Drug Administration (FDA). |

| Governing Quality Standard | USP Chapters <795>, <797>, and <800>. | Current Good Manufacturing Practices (CGMP) and USP Chapters. |

| Sterile Compounding | Permitted for individual patients, following USP <797>. | Permitted in large batches, following CGMP rules which are more stringent than USP <797>. |

| Interstate Shipping | Permitted under certain conditions, often limited by state regulations. | Permitted nationwide as a registered outsourcing facility. |

Academic

A deep appreciation for the safety of compounded hormonal therapies requires an examination of the analytical science that underpins it. Beyond the procedural guidelines of USP chapters and the regulatory structures of the FDA lies the domain of quantitative verification.

This is where a pharmacy moves from following a recipe to proving, with objective, scientific data, that the final preparation is precisely what it purports to be. For therapies that recalibrate the delicate endocrine system, such as Testosterone Replacement Therapy (TRT) or Growth Hormone Peptide Therapy, this analytical validation is paramount.

It ensures not only safety from contaminants but also the chemical integrity and bioavailability necessary to produce the intended physiological response. This is achieved through a triad of specialized testing ∞ potency and purity analysis, sterility and endotoxin screening, and stability studies.

How Do Pharmacies Verify Potency and Purity?

The potency of a compounded medication refers to its strength ∞ the amount of active pharmaceutical ingredient (API) present in the final dosage form. Purity refers to its freedom from contaminants, which can include synthesis byproducts from the API, degradants that form over time, or other foreign substances. The gold-standard analytical technique for confirming both potency and purity in complex pharmaceutical mixtures is High-Performance Liquid Chromatography (HPLC).

HPLC is a powerful separation science. The process begins by dissolving a sample of the compounded preparation in a suitable liquid solvent. This liquid sample is then injected into the HPLC instrument, where it is pushed under high pressure through a column packed with a solid material (the stationary phase).

Because different molecules have different chemical affinities for the stationary phase versus the liquid solvent (the mobile phase), they travel through the column at different speeds. As each separated component exits the column, it passes through a detector (typically a UV detector), which generates a signal.

The result is a chromatogram, a graph showing a series of peaks. Each peak corresponds to a different substance, and the time it takes for a peak to appear (its retention time) helps identify it. The area under the peak is directly proportional to the concentration of that substance in the sample.

By comparing the chromatogram of the compounded medication to that of a pure, reference standard of the API, a pharmacist can quantitatively determine if the medication contains the correct amount of the active drug and if any detectable impurities or degradants are present.

The Assurance of Sterility and Apyrogenicity

For any preparation administered via injection, such as Testosterone Cypionate or Ipamorelin, sterility is an absolute requirement. Sterility is the absence of viable microorganisms like bacteria and fungi. A separate but equally important concept is apyrogenicity, which is the absence of endotoxins.

Bacterial endotoxins are lipopolysaccharides from the cell walls of Gram-negative bacteria that can cause a severe inflammatory response, fever, and even septic shock if injected, even if the bacteria themselves are no longer alive. A medication can be sterile yet still contain dangerous levels of endotoxins.

Two distinct tests are required to confirm both qualities:

- Sterility Testing (per USP <71>) ∞ This test is designed to detect the presence of living microbes. The most common methods are direct inoculation, where a sample of the product is added directly to growth media, and membrane filtration, where the product is filtered through a membrane that captures any microorganisms, which is then cultured. The samples are incubated in specific growth media for 14 days. If no microbial growth is observed after this period, the product is considered sterile. This long incubation period is why sterile products subject to testing cannot be released immediately.

- Bacterial Endotoxin Testing (BET) (per USP <85>) ∞ This test specifically detects the presence of endotoxins. The standard method is the Limulus Amebocyte Lysate (LAL) test, which uses an extract from the blood of the horseshoe crab. This lysate protein clots in the presence of endotoxins. Modern variations of this test are highly sensitive and can provide a quantitative result, ensuring that any endotoxin level is well below the safe limit for parenteral administration. A passing sterility test combined with a passing BET provides comprehensive assurance that an injectable preparation is safe for use.

Analytical testing with methods like HPLC and LAL provides objective, data-driven proof of a compounded medication’s identity, strength, purity, and safety.

Establishing and Validating Beyond-Use Dates

A critical aspect of medication quality is its stability ∞ the extent to which it maintains its original chemical and physical properties over time. For manufactured drugs, this is the expiration date. For compounded preparations, it is the beyond-use date (BUD). A pharmacy cannot arbitrarily assign a BUD; it must be supported by scientific evidence.

This is accomplished through stability studies, which use a stability-indicating analytical method ∞ typically HPLC ∞ to test the preparation at specific time points. The study assesses several key attributes.

The following table provides a simplified example of data from a hypothetical 90-day stability study for a compounded 10% testosterone cream stored at room temperature.

| Test Parameter | Specification | Day 0 | Day 30 | Day 60 | Day 90 |

|---|---|---|---|---|---|

| Potency (% of Label Claim) | 90.0% – 110.0% | 101.2% | 100.8% | 99.7% | 98.5% |

| Appearance | Smooth, white, uniform cream | Pass | Pass | Pass | Pass |

| pH | 4.5 – 6.0 | 5.2 | 5.2 | 5.1 | 5.1 |

| Known Degradants | Not more than 0.5% | <0.1% | <0.1% | 0.15% | 0.21% |

This data demonstrates that the preparation maintains its critical quality attributes within the acceptable range for at least 90 days, providing the scientific justification for assigning a 90-day BUD. Such studies are essential for ensuring that the therapy you use on the last day of its BUD is just as safe and effective as it was on the day it was compounded. This level of analytical diligence is the ultimate expression of a pharmacy’s commitment to patient safety and therapeutic efficacy.

References

- Banov, Daniel, et al. “Testosterone Therapy for Late-Onset Hypogonadism ∞ A Clinical, Biological, and Analytical Approach Using Compounded Testosterone 0.5 ∞ 20% Topical Gels.” Pharmaceutics, vol. 16, no. 5, 2024, p. 621.

- Committee on the Assessment of the Available Scientific Data Regarding the Safety and Effectiveness of Compounded Bioidentical Hormone Replacement Therapy. The Safety and Effectiveness of Compounded Bioidentical Hormone Therapy. National Academies Press, 2020.

- “Compounding Inspections and Oversight Frequently Asked Questions.” U.S. Food and Drug Administration, 23 Apr. 2024.

- “Drug Purity Analysis ∞ A Comprehensive Guide For Biopharmaceutical Professionals.” Alwsci.com, 4 Sept. 2024.

- “FDA Publishes Proposed Rule on 503A and 503B Compounding.” McDermott Will & Emery, 5 Apr. 2024.

- Glasnapp, Andrew. “Factors That Affect the Stability of Compounded Medications.” The PCCA Blog, 16 Mar. 2022.

- Lipcaman, Kayla. “Sterility and Endotoxin.” RXinsider, 2023.

- “The Principle of HPLC and Its application in Pharmaceutical Analysis.” YouTube, uploaded by ATA Scientific Instruments, 3 Mar. 2022.

- United States Pharmacopeial Convention. “USP Quality Standards for Compounding.” USP.org.

- “Why Is HPLC Ideal for Chemical Purity Testing?” Moravek, Inc.

Reflection

The journey into personalized hormonal health is a commitment to understanding the intricate language of your own body. The scientific standards, analytical tests, and regulatory frameworks that govern compounding pharmacies are the grammar and syntax of that language. They provide the structure and reliability needed to translate your unique physiological needs into a safe and effective therapeutic reality.

This knowledge transforms you from a passive recipient of care into an active, informed collaborator in your own wellness. Your path forward is one of continuous dialogue ∞ with your clinician, with your body’s responses, and with the professionals who craft your personalized medicine. The ultimate goal is a state of vitality and function, achieved through a process that respects and validates your individuality at every step.