Fundamentals

You feel the shift in your body. The persistent fatigue, the subtle changes in mood, the sense that your internal settings are no longer calibrated to your life’s demands. This experience, this deeply personal data, is what brings you to consider a personalized wellness protocol.

It is a journey toward understanding your own biological systems to reclaim vitality. Before a single custom-dosed capsule is formulated or a therapeutic solution is prepared, however, a foundational process of verification and protection must occur.

The conversation about your health rightly begins with your symptoms, but the science behind your solution begins with a question of molecular integrity ∞ how can we be certain that the foundational ingredients of your therapy are pure, potent, and stable from the very start?

The answer resides in the rigorous world of pharmaceutical sourcing and quality control, a place where science ensures the promise of personalized medicine is built on a bedrock of reliability. At the heart of any compounded medication is the Active Pharmaceutical Ingredient (API).

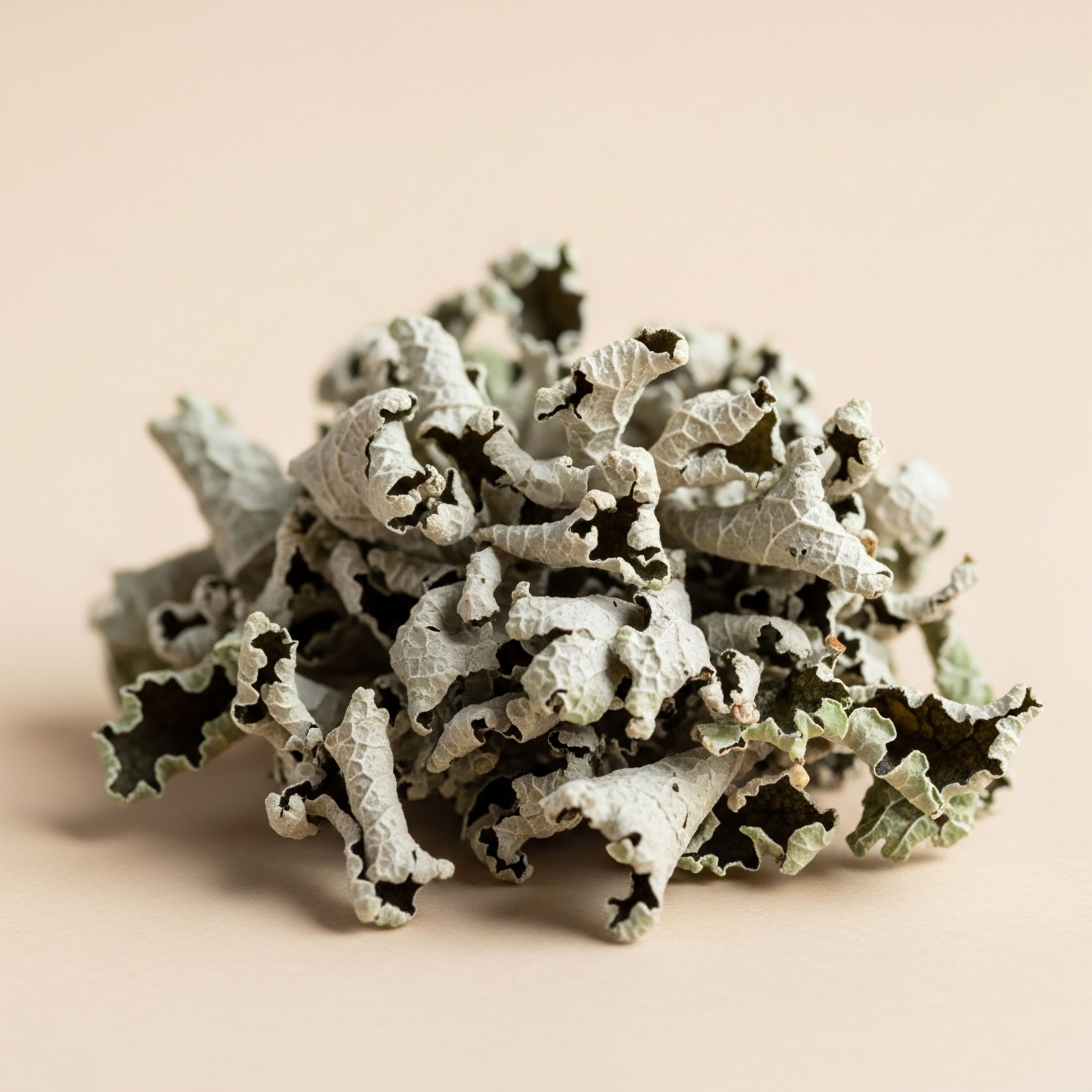

This is the specific molecule, such as Testosterone Cypionate or Ipamorelin, that is biologically active in your body. A compounding pharmacy’s first and most critical responsibility is to ensure the identity, purity, and stability of these APIs. They are the elemental building blocks of your protocol, and their quality is non-negotiable.

The journey of a medication begins long before it is compounded; it starts with the verification and preservation of its core chemical structure.

This process is far more complex than simply ordering a chemical from a supplier. It involves a meticulous verification of the supplier’s credentials and, most importantly, a thorough analysis of the Certificate of Analysis (CofA) that accompanies every batch of raw material.

This document is the API’s passport, detailing its identity, purity, and the results of various quality tests performed by the manufacturer. A reputable compounding pharmacy treats this certificate as a starting point, not a final guarantee. They will often conduct their own independent testing to confirm the information and ensure the API meets the stringent standards set by the United States Pharmacopeia (USP).

The Unseen Forces That Challenge Stability

An API, even one of the highest purity, is a complex molecule susceptible to degradation from environmental forces. Its long-term stability is a measure of how well it resists these changes over time, ensuring that the medication you take in the final week of its use is just as potent and safe as it was on the first day. Several factors can compromise the integrity of these vital raw materials.

- Temperature ∞ Heat can accelerate chemical reactions, causing molecules to break down. Many sensitive APIs, especially complex peptides used in growth hormone therapies, require strict, refrigerated or frozen storage conditions from the moment they arrive at the pharmacy.

- Light ∞ Ultraviolet (UV) radiation from sunlight or even indoor lighting can provide the energy needed to initiate degradation reactions. For this reason, light-sensitive APIs are stored in opaque, amber-colored containers that block out damaging wavelengths.

- Oxygen ∞ The process of oxidation, the same reaction that causes an apple to brown, can degrade certain APIs. This is managed by storing materials in airtight containers, sometimes purged with an inert gas like nitrogen to displace oxygen.

- Moisture ∞ Water is a universal solvent and can facilitate hydrolysis, a chemical reaction where water molecules break down the API. Raw materials are stored in environments with controlled low humidity to prevent this form of degradation.

Ensuring the long-term stability of these raw materials is an active, continuous process. It involves dedicated, climate-controlled storage facilities, meticulous inventory management that follows the “first-in, first-out” principle, and a deep understanding of the unique chemical vulnerabilities of each specific ingredient. This rigorous oversight ensures that the foundational components of your personalized therapy remain pristine, potent, and ready to be compounded into the precise formulation your body needs.

What Is a Stability Indicating Method?

A crucial concept in this field is the use of a stability-indicating method. This refers to a specific type of analytical test designed to do two things. It accurately measures the quantity of the intact API. It also detects and quantifies any substances that are formed as the API degrades.

This distinction is vital. A simple potency test might show that 95% of the active ingredient is present, but it might not reveal that the other 5% has transformed into a different, potentially harmful, chemical.

A stability-indicating method, often using techniques like High-Performance Liquid Chromatography (HPLC), separates the intact drug from its degradation products, providing a complete picture of the material’s chemical health. By using these advanced methods, pharmacies can confidently guarantee the stability and safety of their raw materials over time.

Intermediate

For an individual engaged in a personalized health protocol, understanding the clinical rationale behind your treatment is empowering. This same desire for clarity should extend to the pharmaceutical science that underpins it.

The long-term stability of the raw materials used in your compounded medications is not a passive state; it is the result of a deliberate, multi-layered strategy governed by strict scientific principles and regulatory standards. This strategy ensures that the molecular structure of your therapy remains effective and safe from the supplier to the pharmacy and, ultimately, to you.

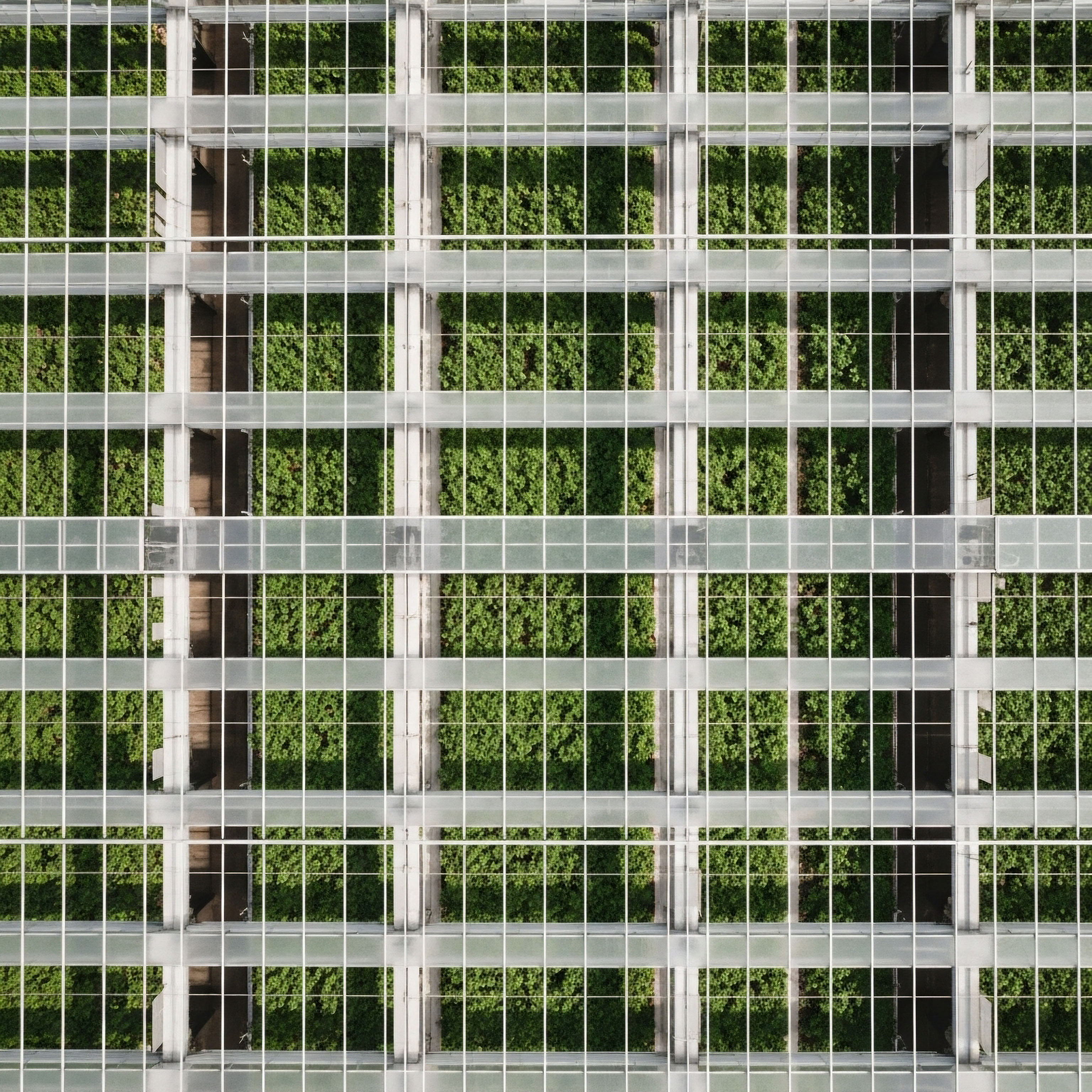

The foundational guidelines for this process are established by the United States Pharmacopeia (USP). Specifically, USP General Chapters like <795> for nonsterile compounding and <797> for sterile compounding provide the framework that responsible pharmacies operate within. These chapters detail requirements for every step of the compounding process, including the initial receipt, storage, and handling of Active Pharmaceutical Ingredients (APIs). Adherence to these standards is a hallmark of a high-quality compounding pharmacy.

A medication’s stability is actively managed through controlled environments and rigorous testing, not passively assumed.

The Lifecycle of a Verified Raw Material

The journey to ensure API stability begins the moment a shipment arrives. It is a systematic process of quarantine, verification, and controlled storage.

- Quarantine and Initial Verification ∞ Upon arrival, a batch of raw material is not immediately placed into general inventory. It is moved to a designated quarantine area. Here, the pharmacy staff verifies the shipment against the purchase order, inspects the packaging for any signs of damage or tampering, and confirms that the Certificate of Analysis (CofA) is present and corresponds to that specific batch number.

- Certificate of Analysis (CofA) Review ∞ The CofA is scrutinized by a trained pharmacist or chemist. This document contains critical data points, including the manufacturer’s test results for identity, purity (usually as a percentage), and levels of any known impurities or heavy metals. The pharmacy compares these results against established USP monograph specifications or their own internal, stricter standards.

- In-House Identity and Potency Testing ∞ Leading pharmacies do not rely solely on the manufacturer’s CofA. They perform their own independent testing on a sample from the quarantined batch. Using analytical instrumentation, they confirm the material’s identity and test its potency. This provides a crucial second layer of verification, protecting against mislabeled materials or those that may have degraded during shipping.

- Controlled Storage and Inventory Management ∞ Once verified, the API is released from quarantine and moved to a dedicated, climate-controlled storage facility. This is not a simple stockroom. These areas have calibrated sensors that continuously monitor and log temperature and humidity. APIs are stored according to their specific needs, which are often dictated by the manufacturer and chemical common sense.

Accelerated versus Real-Time Stability Studies

Compounding pharmacies may also rely on stability studies to assign appropriate beyond-use dates (BUDs) to their preparations. These studies can also inform the storage requirements for the raw materials themselves. There are two primary types of stability studies.

| Study Type | Methodology | Purpose | Limitations |

|---|---|---|---|

| Real-Time Stability Study | The API or finished preparation is stored under its recommended long-term storage conditions (e.g. 25°C/60% RH) and tested at regular intervals (e.g. 3, 6, 9, 12, 24 months) until it fails to meet specifications. | Provides the most reliable data for determining the true shelf life or BUD under normal conditions. | The process is very time-consuming and can take years to complete, making it impractical for short-term needs. |

| Accelerated Stability Study | The API or preparation is subjected to exaggerated stress conditions (e.g. 40°C/75% RH) for a shorter period (e.g. 3-6 months). The degradation at these high-stress conditions is then used to predict long-term stability at normal conditions using chemical kinetic models like the Arrhenius equation. | Offers a rapid prediction of long-term stability, allowing for faster formulation development and BUD assignment. It is also used in forced degradation studies to identify potential breakdown products. | The prediction is a model, not a direct measurement. It may not accurately predict physical changes or complex reactions that do not follow the assumed kinetic model. |

For raw materials, pharmacies typically rely on the real-time stability data provided by the API manufacturer, which is used to establish the material’s expiration date. The pharmacy’s role is to maintain the validated storage conditions to ensure that this expiration date remains valid. Any deviation from these conditions, such as a prolonged power outage affecting a refrigerator, must be documented, and the integrity of the stored materials must be re-evaluated.

What Are the Primary Degradation Pathways?

Understanding the chemical “how” of instability is key to preventing it. Most APIs are susceptible to a few common types of chemical reactions that break them down. A pharmacist’s knowledge of these pathways informs the specific storage and handling protocols for each raw material.

- Hydrolysis ∞ This is a reaction with water. Esters and amides, which are chemical structures found in many drugs (including testosterone esters like cypionate), are particularly susceptible. This is why controlling humidity is so critical.

- Oxidation ∞ This is a reaction involving the loss of electrons, often facilitated by oxygen. Phenols, aldehydes, and ethers are functional groups that can be prone to oxidation. Storing materials in airtight containers, away from light, and sometimes under an inert gas blanket mitigates this risk.

- Photolysis ∞ This is degradation caused by exposure to light, particularly UV light. The energy from photons can break chemical bonds. This is why so many pharmaceutical chemicals are stored in dark, amber glass or completely opaque containers.

By understanding these fundamental degradation pathways, a compounding pharmacy can proactively design its storage and handling procedures. This scientific foresight is a critical component in ensuring the long-term stability of the verified raw materials that form the basis of personalized hormonal and metabolic therapies.

Academic

A sophisticated appreciation of personalized medicine requires an examination of the rigorous science that ensures its safety and efficacy at the molecular level. The long-term stability of an Active Pharmaceutical Ingredient (API) within a compounding pharmacy is a subject of intense scientific and regulatory scrutiny.

It is governed by the principles of physical organic chemistry, analytical chemistry, and pharmaceutical quality systems. The integrity of a final compounded preparation is wholly dependent on the validated stability of its constituent raw materials, a concept that is enforced through a combination of supplier qualification, robust internal testing, and meticulously controlled environmental conditions.

The regulatory foundation for these practices in the United States is the Food, Drug, and Cosmetic Act (FD&C Act), which grants the United States Pharmacopeia (USP) the authority to set official standards. High-quality compounding pharmacies integrate USP chapters <795>, <797>, and <1191> (Stability Considerations in Dispensing Practice) into their Quality Management System (QMS). This system treats API stability not as a static property but as a dynamic state that must be actively preserved and continuously verified.

The chemical kinetics of degradation dictate the precise environmental controls and analytical methods required to ensure API stability.

Forced Degradation Studies and Stability-Indicating Method Validation

A cornerstone of ensuring API integrity is the use of a validated stability-indicating analytical method (SIAM). The development of a SIAM is a complex process that begins with forced degradation studies. In these studies, the pure API is intentionally subjected to extreme chemical and physical stresses that are far more severe than any conditions it would encounter during normal storage. These stresses typically include:

- Acid Hydrolysis ∞ Exposure to a strong acid (e.g. 0.1 N HCl) at elevated temperatures.

- Base Hydrolysis ∞ Exposure to a strong base (e.g. 0.1 N NaOH) at elevated temperatures.

- Oxidation ∞ Exposure to an oxidizing agent, such as hydrogen peroxide (H₂O₂).

- Thermal Stress ∞ Exposure to high heat in a dry oven.

- Photolytic Stress ∞ Exposure to high-intensity UV and visible light in a photostability chamber.

The purpose of this deliberate degradation is to generate the likely breakdown products of the API. An analytical technique, most commonly High-Performance Liquid Chromatography (HPLC) with a photodiode array (PDA) or mass spectrometry (MS) detector, is then used to analyze these stressed samples.

The goal is to develop a method that can achieve complete chromatographic separation between the peak representing the intact API and the peaks of all its degradation products and any known impurities. Method validation ensures the SIAM is accurate, precise, specific, linear, and robust. Only after this rigorous validation can the method be reliably used to assess the stability of incoming raw materials and finished preparations.

Chemical Kinetics and Environmental Control

The rate at which an API degrades can be described by chemical kinetics. While some reactions are zero-order, many degradation processes follow first-order kinetics, where the rate of degradation is directly proportional to the concentration of the API. The influence of temperature on this rate is often modeled by the Arrhenius equation ∞ k = Ae^(-Ea/RT).

This equation illustrates that the rate constant (k) of a reaction increases exponentially with temperature (T). This is the scientific reason that temperature control is the most critical factor in preserving API stability. A seemingly minor deviation, such as storing a temperature-sensitive peptide at room temperature for a few hours, can cause a significant and irreversible loss of potency.

Compounding pharmacies must therefore utilize calibrated, continuously monitored, and alarmed refrigerators and freezers with backup power systems to house their temperature-sensitive raw materials.

| API Class | Example(s) | Primary Degradation Risks | Standard Storage Conditions |

|---|---|---|---|

| Steroid Hormones | Testosterone Cypionate, Progesterone (micronized powder) | Oxidation, Photolysis | Controlled Room Temperature (20-25°C), protected from light, in well-sealed containers. |

| Peptide Hormones | Sermorelin, Ipamorelin, CJC-1295 | Hydrolysis, Oxidation, Thermal Degradation | Refrigerated (2-8°C) or Frozen (≤ -20°C) as a lyophilized powder, protected from light. Highly sensitive to temperature excursions. |

| Aromatase Inhibitors | Anastrozole | Generally stable, but susceptible to hydrolysis under extreme pH conditions. | Controlled Room Temperature (20-25°C), in well-sealed containers. |

| Thyroid Hormones | Levothyroxine (T4) | Photolysis, Oxidation, Moisture-induced degradation. | Controlled Room Temperature (20-25°C), tightly sealed, and fully protected from light. |

Supplier Qualification and Ongoing Verification

How can a pharmacy trust the source of its raw materials? A robust supplier qualification program is essential. This is a formal process for vetting manufacturers and distributors of APIs. It involves:

- Regulatory Compliance Check ∞ Confirming the supplier is registered with the FDA and operates out of a cGMP (Current Good Manufacturing Practices) compliant facility.

- Auditing ∞ For critical APIs, this may involve a direct audit of the manufacturer’s facility to inspect their quality control processes, documentation practices, and production environment.

- Historical Performance Review ∞ Tracking the quality of batches received from a supplier over time. This includes monitoring the results of in-house verification tests and noting any trends or inconsistencies.

- Documentation Scrutiny ∞ Evaluating the completeness and professionalism of their Certificates of Analysis and their responsiveness to requests for additional information.

This rigorous initial and ongoing qualification process ensures that the pharmacy is sourcing materials from partners who share their commitment to quality. The pharmacy’s own internal testing then serves as the final check, confirming that the material received meets the required specifications. This dual-layered approach of external validation and internal verification is the academic and practical gold standard for ensuring the long-term stability and quality of all raw materials used in advanced compounding.

References

- Allen, Loyd V. “Chapter 6 ∞ Stability of Compounded Preparations.” The Art, Science, and Technology of Pharmaceutical Compounding, 6th ed. American Pharmacists Association, 2020.

- United States Pharmacopeial Convention. “General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF).

- United States Pharmacopeial Convention. “General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations.” United States Pharmacopeia and National Formulary (USP-NF).

- United States Pharmacopeial Convention. “General Chapter <1191> Stability Considerations in Dispensing Practice.” United States Pharmacopeia and National Formulary (USP-NF).

- Gudeman, J. et al. “Stability of Compounded Formulations ∞ A Review of the Literature.” International Journal of Pharmaceutical Compounding, vol. 17, no. 1, 2013, pp. 34-41.

- “Strength and Stability Testing for Compounded Preparations.” USP Compounding Expert Committee, 13 Jan. 2014.

- Baertschi, S. W. & Alsante, K. M. “Pharmaceutical Stress Testing ∞ Predicting Drug Degradation.” Pharmaceutical Technology, vol. 40, no. 5, 2016, pp. 34-43.

- “Stability Reference Document for Pharmaceutical Compounding.” Pharmacopeial Forum, vol. 50, no. 6, 2024.

Reflection

Calibrating Your Internal Systems

The information presented here details the immense scientific diligence required to protect the integrity of a single therapeutic molecule. It is a process of control, verification, and foresight, all designed to deliver a predictable biological effect. Your own body operates on similar principles.

It is a complex system striving for equilibrium, constantly sending signals about its state through the language of symptoms and sensations. Understanding the science behind your therapy is the first step. The next is to apply that same level of mindful observation to your own life.

How do your inputs ∞ nutrition, sleep, stress, movement ∞ affect your internal stability? Viewing your health journey through this lens transforms you from a passive recipient of care into an active partner in your own biological calibration. The ultimate goal is to create a state of personal stability where your vitality and function are not just restored, but resilient.