Fundamentals

Embarking on a journey to optimize your endocrine health is a profound act of self-stewardship. You are seeking to recalibrate the very systems that govern your energy, mood, and vitality. Central to this process is a deep and abiding trust in the therapeutic agents you use.

This trust, however, must be placed not just in the name on the vial, but in the molecular integrity of its contents. The safety and success of any combined endocrine protocol are anchored in the concept of biochemical integrity, a principle that defines a substance by its absolute purity, structural correctness, and freedom from bioactive contaminants. Understanding how commercial sourcing practices influence this integrity is the first step toward ensuring your protocol supports your biology as intended.

Your body’s hormonal system operates with breathtaking precision. Hormones like testosterone function as specific keys designed to fit into cellular locks, known as receptors. When a correctly shaped testosterone cypionate molecule binds to its androgen receptor, it initiates a cascade of desired biological events. Commercial sourcing practices determine the quality of that key.

The highest standard, pharmaceutical-grade manufacturing, operates under stringent regulations to produce molecules that are chemically exact replicas of the intended hormone. These facilities are designed to guarantee that each vial contains almost exclusively the active compound, ensuring the key is cut with near-perfect precision.

The Spectrum of Sourcing

The journey of a hormone from synthesis to syringe passes through different channels, each with its own level of oversight and quality assurance. At one end of the spectrum lies the FDA-regulated pharmaceutical manufacturer. These entities produce the brand-name medications available at standard pharmacies. Their processes are rigorously validated, audited, and controlled to ensure every batch meets exacting standards for identity, strength, purity, and quality. This is the benchmark for biochemical integrity.

Next are compounding pharmacies. These facilities play a valuable role in medicine by creating customized formulations for patients. For endocrine protocols, they might prepare testosterone cypionate in a different carrier oil or at a specific concentration unavailable commercially.

When operating under strict adherence to United States Pharmacopeia (USP) standards, particularly USP 797 for sterile compounding, these pharmacies can produce high-quality, safe preparations. The variability in oversight from state to state, however, means that the quality can differ significantly between facilities. The potential for deviation from ideal standards is a consideration in this space.

A third category involves suppliers who provide substances labeled for “research use only.” These materials are not intended for human consumption and are not produced under the same Good Manufacturing Practices (GMP) required for pharmaceuticals. The quality controls for these products are focused on academic or laboratory applications, where the standards for sterility and the absence of certain contaminants may be different from those required for injectable medications.

Impurities the Unwanted Signals

What exactly compromises biochemical integrity? The threats can be categorized into two main groups. The first is the presence of related chemical impurities. During the synthesis of testosterone cypionate, for instance, other similar molecules can be created as byproducts.

These are like poorly copied keys; they might be close enough to the real thing to fit in the receptor’s lock but are unable to turn it, effectively blocking the receptor. Some might even partially activate it, leading to unpredictable or weakened effects. A sourcing process with robust quality control uses sophisticated techniques like high-performance liquid chromatography (HPLC) to detect and remove these related impurities, ensuring the final product is composed almost entirely of the desired active molecule.

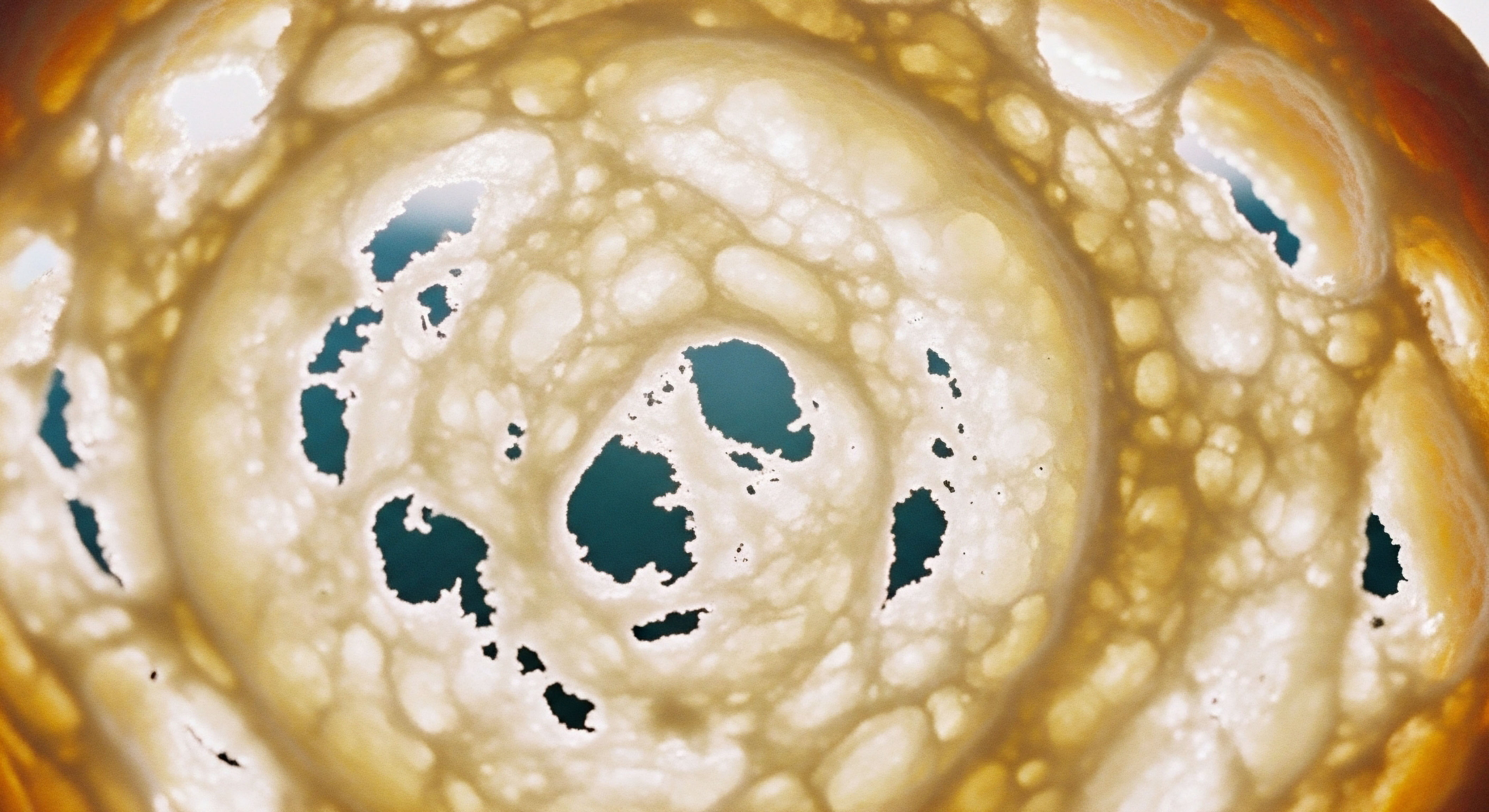

A hormone’s effectiveness depends on its precise molecular structure fitting into a cellular receptor, much like a key fits a lock.

The second, and more acutely dangerous, category of contaminant is the endotoxin. Endotoxins, specifically lipopolysaccharides (LPS), are fragments of the cell walls of gram-negative bacteria. They are ubiquitous in the environment and can be introduced into a product through contaminated raw materials or non-sterile manufacturing processes.

Even in microscopic amounts, endotoxins are potent triggers of the human immune system. Their presence in an injectable medication can provoke a significant inflammatory response, leading to fever, body aches, and a general feeling of illness. In severe cases, it can cause systemic inflammation that undermines the very goals of the endocrine protocol. Reputable sourcing practices involve rigorous testing for endotoxins to ensure the final product is safe for injection.

Intermediate

Advancing from foundational concepts, we can now examine the direct impact of sourcing on the specific, multi-component protocols used in hormonal optimization. The safety of a combined therapy is a chain, and its strength is determined by its weakest link.

Each element of the protocol, from the primary hormone to the supportive ancillaries and peptides, carries its own sourcing-dependent risk profile. A failure in the biochemical integrity of any single component can compromise the safety and efficacy of the entire system, creating a cascade of unintended biological consequences.

Deconstructing the TRT Protocol

A standard male testosterone replacement therapy (TRT) protocol illustrates this interconnectedness perfectly. It typically involves Testosterone Cypionate, an aromatase inhibitor like Anastrozole, and a gonadotropin-releasing hormone analogue like Gonadorelin. Each of these must be sourced with equal diligence.

- Testosterone Cypionate ∞ The active hormone is suspended in a carrier oil, often cottonseed or sesame oil. Sourcing practices affect both elements. A poorly refined carrier oil can contain its own inflammatory compounds or impurities. The testosterone ester itself must be pure. As studies on its pharmacokinetics show, the ester tail (the cypionate part) is designed to control the hormone’s release into the bloodstream. The presence of improperly formed esters or related steroid compounds can alter this release profile, causing unpredictable peaks and troughs in testosterone levels. This leads to fluctuating symptoms and a more difficult path to stabilization.

- Anastrozole ∞ This oral medication is used to control the conversion of testosterone to estrogen. Its role is to maintain a healthy hormonal balance. If the sourced Anastrozole is under-dosed due to poor quality control, estrogen levels can rise excessively, leading to side effects like water retention and gynecomastia. Conversely, an over-dosed or contaminated product could suppress estrogen too severely, resulting in joint pain, low libido, and negative impacts on bone density and cardiovascular health.

- Gonadorelin ∞ This peptide is used to maintain testicular function and endogenous testosterone production. Peptides are notoriously fragile molecules. Sourcing from a non-GMP facility dramatically increases the risk of receiving a product with an incorrect amino acid sequence, or one that has degraded due to improper handling. An ineffective Gonadorelin preparation fails to stimulate the pituitary, leading to testicular atrophy and a more difficult recovery should the patient ever decide to cease TRT.

For women, hormonal protocols involving low-dose testosterone, progesterone, or pellet therapies face identical challenges. The precision required for female hormone balance is even finer, and the introduction of a contaminated or inaccurately dosed product can disrupt the menstrual cycle, mood, and overall well-being with profound effects.

How Does Sourcing Affect Peptide Therapy Safety?

The world of peptide therapies, such as those involving Sermorelin, Ipamorelin/CJC-1295, or PT-141, presents an even higher level of sourcing complexity. These are large, intricate molecules built from specific sequences of amino acids. Their biological function is entirely dependent on their exact structure.

Commercial sourcing practices for peptides determine several critical quality attributes:

- Sequence Accuracy ∞ The primary structure must be correct. A single wrong amino acid can render the peptide inert or, in some cases, cause it to bind to unintended receptors.

- Purity Level ∞ Synthesis of peptides is a complex chemical process that generates numerous byproducts, including truncated sequences (incomplete peptides) and deletion sequences. High-purity peptides, often greater than 99% as verified by HPLC, are essential for predictable effects and safety. Low-purity products introduce a cocktail of unknown peptide fragments into the body.

- Sterility and Endotoxins ∞ As with hormone therapies, injectable peptides must be sterile and free of endotoxins. The risk of bacterial contamination is significant in non-GMP environments, and the consequences of injecting endotoxins alongside a growth hormone secretagogue can include systemic inflammation that directly counteracts the intended anti-aging and recovery benefits.

The safety of a multi-drug hormonal protocol is only as strong as the purity and accuracy of its most poorly sourced component.

The table below contrasts the characteristics of a peptide sourced from a GMP-compliant facility versus a lower-grade “research” supplier, highlighting the tangible differences in the final product.

| Quality Attribute | GMP-Compliant Sourcing | “Research Use Only” Sourcing |

|---|---|---|

|

Purity (HPLC) |

Typically >99%, with a certificate of analysis specifying impurities. |

Often lower and variable (e.g. 95-98%), with fewer details on the nature of impurities. |

|

Endotoxin Testing |

Mandatory testing to ensure levels are below the safe threshold for injection. |

May not be performed, or standards may be lax. High risk of LPS contamination. |

|

Sterility |

Produced and packaged in an aseptic environment to guarantee sterility. |

Often handled in a non-sterile lab environment; risk of microbial contamination is high. |

|

Vial Contents |

Accurate peptide mass, often with specific stabilizing agents (excipients). |

Inaccurate peptide amount, often filled with bulking agents like mannitol without proper formulation. |

Academic

A granular analysis of protocol safety requires moving beyond visible contaminants to the molecular level, specifically examining the immunological consequences of endotoxin contamination in parenterally administered endocrine therapies. The presence of lipopolysaccharide (LPS), even at concentrations undetectable without specialized assays, initiates a potent and often counterproductive inflammatory cascade.

This response is mediated primarily through the innate immune system’s pattern recognition receptors, with Toll-like receptor 4 (TLR4) serving as the principal sensor for LPS. Understanding this pathway reveals how poor commercial sourcing can actively sabotage the physiological goals of a meticulously planned endocrine protocol.

The TLR4 Pathway a Molecular Alarm System

When an injectable therapeutic contaminated with LPS is administered, the LPS molecules are immediately recognized by LPS-binding protein (LBP) in the plasma. This complex then facilitates the transfer of LPS to the CD14 receptor, which in turn presents the LPS to the TLR4-MD2 receptor complex on the surface of immune cells like macrophages and monocytes.

This binding event is the critical trigger. It initiates a conformational change in the TLR4 receptor, leading to the recruitment of intracellular adaptor proteins, primarily MyD88 and TRIF. This single event bifurcates into two powerful signaling arms.

The MyD88-dependent pathway rapidly activates the transcription factor NF-κB (nuclear factor kappa-light-chain-enhancer of activated B cells). Activated NF-κB translocates to the nucleus and induces the transcription of genes for a host of pro-inflammatory cytokines, including tumor necrosis factor-alpha (TNF-α), interleukin-1β (IL-1β), and interleukin-6 (IL-6).

These cytokines are the primary mediators of the acute inflammatory response, responsible for symptoms like fever, malaise, and localized pain. The TRIF-dependent pathway, on the other hand, leads to the activation of interferon regulatory factor 3 (IRF3), which drives the production of type I interferons, further amplifying the immune alert.

What Are the Cascading Failures in a Non-GMP Production Chain?

A production environment that lacks adherence to Good Manufacturing Practices (GMP) introduces multiple failure points where microbial and endotoxin contamination can occur. These failures are not isolated incidents; they represent a systemic breakdown in quality control that directly translates to patient risk.

- Raw Material Control ∞ The initial amino acids, solvents, and reagents used for synthesis may arrive with a significant bioburden. A non-GMP process may lack the stringent incoming material inspection and testing required to reject contaminated lots.

- Process Water ∞ The water used during synthesis and purification must be of the highest purity (Water for Injection, WFI). Standard distilled or deionized water can harbor gram-negative bacteria, seeding the entire production process with LPS.

- Aseptic Technique ∞ The handling of the purified peptide, its lyophilization (freeze-drying), and its final packaging into vials must occur in a sterile environment (an aseptic processing area). Inadequate environmental monitoring, improper gowning procedures, and poorly maintained cleanrooms are common failure points that allow for microbial contamination of the final product.

- Depyrogenation ∞ Glassware and equipment must be rendered free of endotoxins, a process called depyrogenation, which typically requires high heat (e.g. 250°C). Failure to properly execute and validate this step leaves residual LPS on surfaces that come into contact with the product.

Systemic Inflammation the Antithesis of Optimization

The clinical implications of this low-grade, or in some cases acute, endotoxemia are profound. The very state of chronic, low-grade inflammation induced by contaminated injectables is diametrically opposed to the goals of most endocrine and peptide therapies. Many individuals seek these protocols to combat age-related inflammation, improve metabolic function, and enhance tissue repair. The introduction of LPS actively undermines these objectives.

Endotoxin contamination transforms a therapeutic injection into an inflammatory trigger, directly opposing the protocol’s intended biological benefits.

For example, a patient on TRT to improve insulin sensitivity and body composition will find their progress impeded by the inflammatory effects of IL-6 and TNF-α, both of which are known to promote insulin resistance.

A patient using growth hormone peptides like Sermorelin or Ipamorelin to improve sleep and recovery will find that the systemic inflammation driven by LPS disrupts sleep architecture and places an additional catabolic stress on the body. The table below details this conflict between the goals of therapy and the effects of LPS-induced inflammation.

| Therapeutic Goal | Mechanism of Action | How LPS Contamination Interferes |

|---|---|---|

|

Improved Insulin Sensitivity (TRT) |

Testosterone improves glucose uptake in muscle and reduces visceral fat. |

TNF-α and IL-6, induced by LPS, phosphorylate insulin receptor substrate-1 (IRS-1) at serine residues, inhibiting insulin signaling. |

|

Enhanced Tissue Repair (GH Peptides) |

Increased pulsatile growth hormone release stimulates IGF-1, promoting cellular repair and protein synthesis. |

Inflammatory cytokines create a catabolic environment, increasing cortisol and diverting metabolic resources away from anabolism and toward the immune response. |

|

Reduced Systemic Inflammation (General Wellness) |

Balancing hormones and using specific peptides can lower baseline inflammatory markers like C-reactive protein (CRP). |

LPS is a direct and potent inducer of the very inflammatory pathways the therapy seeks to quell, raising CRP and other markers. |

|

Improved Libido and Well-being (TRT) |

Direct central nervous system effects of testosterone and balanced estrogen. |

Pro-inflammatory cytokines are well-known mediators of “sickness behavior,” which includes lethargy, anhedonia, and loss of libido. |

Therefore, the commercial sourcing of endocrine therapeutics is a critical determinant of patient safety at a deep, immunological level. A failure to control for endotoxin contamination converts a therapeutic intervention into a vector for systemic inflammation, a state that is fundamentally incompatible with the goals of achieving optimal health and function.

References

- Sutton, James, and Nitesh K. K. Trivedi. “Moulds associated with contaminated ocular and injectable drugs ∞ FDA recalls, epidemiology considerations, drug shortages, and aseptic processing.” Medical Mycology, vol. 56, no. suppl_1, 2018, pp. 122-140.

- “Guidance for Industry Pyrogen and Endotoxins Testing ∞ Questions and Answers.” U.S. Food and Drug Administration, 2012.

- Gomes, Patrícia S. et al. “Aspects of complexity in quality and safety assessment of peptide therapeutics and peptide-related impurities. A regulatory perspective.” Toxicology and Applied Pharmacology, vol. 498, 2024, p. 105699.

- “Pharmacokinetics of testosterone therapies in relation to diurnal variation of serum testosterone levels as men age.” Andrology, vol. 6, no. 5, 2018, pp. 699-709.

- Hanisch, Uwe-Karsten, and Michael R. Weinstein. “Lipopolysaccharide is a frequent and significant contaminant in microglia-activating factors.” Glia, vol. 56, no. 1, 2008, pp. 15-26.

- “Oversight Improves After Contaminated Compounded Drugs Killed Dozens, but Risks Remain.” The Pew Charitable Trusts, 2017.

- “Unsafe Injection Practices.” Centers for Disease Control and Prevention, 2024.

- “Quality Control and Assurance in GMP Peptide Production.” Creative Peptides.

- “Testosterone cypionate.” National Institute of Standards and Technology (NIST) Chemistry WebBook.

- Shoskes, Daniel A. et al. “Pharmacology of testosterone replacement therapy preparations.” Translational Andrology and Urology, vol. 5, no. 6, 2016, pp. 834-843.

Reflection

You began this exploration seeking to understand the safety of your endocrine protocol. The knowledge you now possess about biochemical integrity, sourcing channels, and the silent threat of contaminants like endotoxins is more than just academic. It is a powerful lens through which to view your personal health journey.

It equips you to engage in a more meaningful dialogue with your healthcare provider, shifting the conversation from “what” medication you are taking to “where” it comes from and “how” its quality is assured. This deeper level of inquiry is not an act of distrust, but one of partnership and informed participation in your own care.

Your biology is unique, and the path to optimizing it requires both a precise clinical strategy and an unwavering commitment to the quality of the tools used to execute it. The ultimate responsibility for navigating this path is a shared one, and your proactive engagement is the most vital component.