Fundamentals

Your journey toward hormonal balance is a deeply personal one. You have likely arrived here after careful observation of your body’s signals, seeking answers that align with your unique physiology. The decision to explore a personalized therapeutic path, such as a precisely dosed hormone protocol, reflects a commitment to reclaiming your vitality.

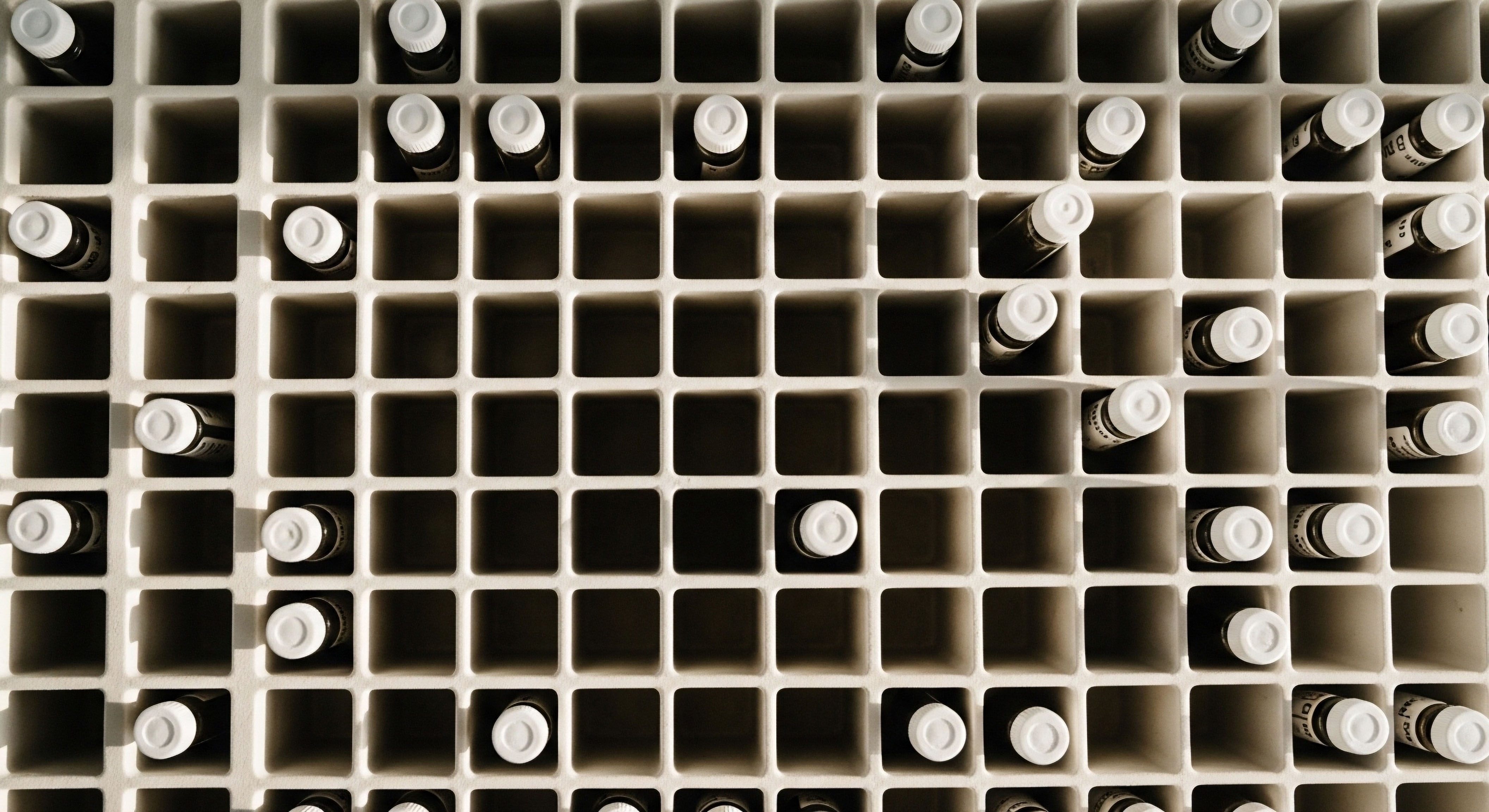

This path often leads to a compounding pharmacy, a place where medicine is tailored to the individual. Here, a pharmacist combines specific ingredients in the exact strength and dosage form required by you, a process that stands apart from mass-produced pharmaceuticals.

This customization is a powerful clinical tool. It allows for the creation of hormone therapies that meet your body’s specific needs, whether that involves a low-dose testosterone cream for a woman, a specific concentration of Testosterone Cypionate for a man’s TRT protocol, or a combination of peptides like Ipamorelin and CJC-1295 for metabolic support.

The very essence of this practice is its precision. The trust you place in this process is immense, as the effectiveness of your protocol depends entirely on the accuracy and purity of the compounded preparation.

The integrity of any personalized hormone protocol is directly linked to the quality of the compounded medication itself.

The Silent Guardian of Your Health

Behind every effective compounded medication stands a rigorous system of quality control. This system is the silent guardian of your health, a series of meticulous steps designed to ensure that what is on the label is exactly what is in the medication.

It encompasses everything from the source and purity of the raw ingredients to the sterile conditions of the laboratory and the final verification of the product’s potency. When this system functions correctly, you receive a medication that is safe, effective, and precisely what your clinician intended.

The foundational standards for this system are set by the United States Pharmacopeia (USP), a scientific organization that establishes benchmarks for the quality of medicines. Chapters like USP 795 (for non-sterile preparations like creams or capsules) and USP 797 (for sterile preparations like injections) provide a detailed blueprint for safe compounding. Adherence to these standards is a non-negotiable aspect of patient safety.

What Are the Pressures on Quality?

The world of healthcare operates within a complex economic environment. Compounding pharmacies, like any specialized service, face business realities that can create tension with the unyielding demands of quality control. These commercial pressures can manifest in various ways, from the cost of high-grade ingredients to the investment required for sophisticated testing equipment and highly trained personnel.

The challenge for any compounding pharmacy is to manage these operational realities without compromising the quality of the medications they produce. Understanding this dynamic is the first step toward becoming an informed and empowered patient, capable of navigating your health journey with clarity and confidence.

Intermediate

As you deepen your understanding of personalized hormonal health, it becomes valuable to examine the specific forces that can influence the quality of your compounded medications. The economic realities of running a highly specialized pharmacy can create direct conflicts with the stringent requirements of quality assurance. Acknowledging these pressures allows you to appreciate the characteristics of a pharmacy that prioritizes patient safety above all else.

The Economics of Purity and Precision

Several key areas in the compounding process are susceptible to commercial pressures. Each represents a point where a pharmacy must make a choice between cost-saving measures and the highest standards of quality.

- Raw Material Sourcing ∞ The active pharmaceutical ingredients (APIs), such as testosterone or progesterone powder, are the foundation of your medication. High-quality, USP-grade ingredients from reputable suppliers cost more than materials from less regulated sources. A pharmacy under financial strain might be tempted to procure lower-grade APIs, which can introduce impurities or have inconsistent potency.

- Investment in Environment ∞ For sterile compounds like injectable Testosterone Cypionate or peptide therapies, the environment is critical. A state-of-the-art cleanroom, compliant with USP 797 standards, requires significant capital investment and ongoing operational costs for air filtration, surface testing, and environmental monitoring. Cutting corners here directly increases the risk of microbial contamination.

- Third-Party Potency Testing ∞ How do you know the cream or injection you received contains the exact dose prescribed? The most reliable method is through batch testing by an independent analytical laboratory. This process, often using techniques like High-Performance Liquid Chromatography (HPLC), confirms the potency and purity of a compounded product. This testing is expensive, and a pharmacy might choose to test less frequently, or not at all, to reduce expenses.

- Personnel and Training ∞ Compounding is a skill that requires extensive training and continuous education, especially in aseptic techniques for sterile preparations. Investing in highly qualified pharmacists and technicians, and providing them with ongoing training, is a significant operational cost.

Commercial pressures can tempt pharmacies to compromise on ingredient quality, environmental controls, and product testing, all of which are invisible to the patient.

The Regulatory Framework a Tale of Two Pharmacy Types

The Food and Drug Administration (FDA) and state boards of pharmacy provide oversight for compounding, but the level of regulation depends on the type of pharmacy. Understanding this distinction is important for any patient receiving compounded medications.

The majority of compounding pharmacies are designated as 503A facilities. They are licensed by state boards of pharmacy and are intended to compound medications based on individual patient prescriptions. They must follow USP standards, but they are not required to register with the FDA or adhere to full Current Good Manufacturing Practices (cGMP), the rigorous standards required of pharmaceutical manufacturers.

A smaller category of pharmacies, known as 503B outsourcing facilities, was created in response to safety incidents. These facilities can produce large batches of compounded drugs without a prescription, which can then be sold to healthcare facilities. In exchange for this ability, they must register with the FDA and adhere to full cGMP requirements, a much higher standard of quality control.

For a patient, knowing whether their medication comes from a 503A or 503B facility provides insight into the regulatory standards it was produced under.

Identifying a High-Quality Compounding Pharmacy

As a patient, you have the right to know about the quality standards of your pharmacy. Here is a comparison of practices that can help you assess where a pharmacy places its priorities.

| Quality Indicator | High-Quality Practice (Patient-Centric) | Lower-Quality Practice (Cost-Centric) |

|---|---|---|

| Ingredient Sourcing | Exclusively uses USP-grade active ingredients from FDA-registered suppliers. Provides Certificates of Analysis (COA) upon request. | May use non-USP ingredients or source from suppliers with less stringent quality control to reduce costs. |

| Potency Testing | Conducts regular, independent third-party testing on batches of compounded medications to verify potency and purity. | Relies solely on theoretical calculations without independent verification, or tests infrequently. |

| Transparency | Openly discusses their quality control procedures, accreditations (like PCAB), and provides testing results to patients and prescribers. | Is vague about quality control processes and may be unwilling to share documentation or testing data. |

| Facility Standards | Maintains and regularly certifies cleanroom environments that meet or exceed USP 797 standards for sterile compounding. | May have inadequate environmental controls, increasing the risk of contamination for sterile products. |

Academic

A sophisticated examination of quality control in compounding pharmacies, particularly in the context of hormonal therapies, requires a deep look into the analytical chemistry and microbiology that underpin patient safety. Commercial pressures do not simply represent a philosophical conflict; they create quantifiable risks that can be measured in terms of chemical purity, microbial load, and, ultimately, clinical outcomes. The integrity of a patient’s hormonal optimization protocol is contingent upon the molecular accuracy of the compounded preparation.

The Analytical Imperative Potency and Purity

For hormonal therapies, the therapeutic window can be narrow. A deviation of even 10-15% from the prescribed dose of a potent androgen like testosterone can mean the difference between effective treatment and sub-therapeutic outcomes or unwanted side effects. The gold standard for verifying the potency of these preparations is High-Performance Liquid Chromatography (HPLC). This analytical technique separates, identifies, and quantifies each component in a mixture, providing a precise measurement of the active ingredient’s concentration.

However, running an HPLC analysis is a resource-intensive process. It requires expensive equipment, specialized consumables, and highly trained personnel. The economic pressure to forgo this step is substantial. A pharmacy might rationalize that their calculations are sufficient, but this ignores the inherent variability in raw materials and the potential for human error in the compounding process.

Studies have shown significant variance in the potency of compounded hormonal preparations, with some containing substantially less or more of the active ingredient than stated on the label. This variance directly undermines the principle of personalized medicine.

The decision to invest in rigorous analytical testing like HPLC is a clear indicator of a pharmacy’s commitment to clinical precision over profit margins.

The Unseen Threat Endotoxin Contamination in Sterile Compounding

For injectable therapies, including Testosterone Cypionate, Gonadorelin, and various peptide protocols (Sermorelin, Ipamorelin), sterility is paramount. The absence of viable microorganisms (bacteria, fungi) is a baseline requirement. A further, more insidious threat is the presence of endotoxins. These are fragments of the cell wall of gram-negative bacteria that remain even after the bacteria are killed by sterilization. When injected, endotoxins can trigger a potent inflammatory response in the body, leading to fever, inflammation, and in severe cases, septic shock.

Preventing endotoxin contamination requires meticulous control over the entire sterile compounding process, starting with the sourcing of raw materials. APIs and other components must be certified as having low endotoxin levels. The water used in compounding must be sterile and pyrogen-free.

The final product should be tested for endotoxins using a method like the Limulus Amebocyte Lysate (LAL) test. Each of these steps adds cost and complexity to the compounding process. Commercial pressures can lead to the use of non-sterile or lower-grade APIs in an attempt to produce a sterile final product, a practice that carries a high risk of endotoxin contamination.

How Can Business Models Influence Quality?

The business model of a compounding pharmacy can itself create pressures that impact quality. A pharmacy focused on high-volume production of a few popular formulations (like weight-loss or hormone creams) may be incentivized to streamline processes in ways that compromise individualization and quality control.

This can lead to a “one-size-fits-all” approach to compounding that is at odds with the goal of personalized medicine. Conversely, a pharmacy that builds its reputation on clinical collaboration and patient outcomes is more likely to invest in the systems and processes that ensure quality, even if it means lower profit margins on individual prescriptions.

The following table illustrates the potential variance in quality based on the analytical testing of compounded Testosterone cream from different pharmacy models.

| Pharmacy Model | Stated Potency (Testosterone 10%) | Actual Potency (HPLC Analysis) | Clinical Implication |

|---|---|---|---|

| High-Volume, Low-Cost Model | 100 mg/gram | 82 mg/gram (-18%) | Sub-therapeutic dosing, lack of symptom improvement, patient frustration. |

| Standard 503A Pharmacy (No Routine Testing) | 100 mg/gram | 115 mg/gram (+15%) | Supra-physiological dosing, increased risk of side effects like aromatization to estrogen. |

| Quality-Focused 503A/503B Facility | 100 mg/gram | 99 mg/gram (-1%) | Accurate, reliable dosing that aligns with the prescriber’s clinical intent. |

This data, while illustrative, reflects the reality that without independent verification, the medication a patient receives may not be the medication that was prescribed. The financial pressures to avoid the costs of such verification are a significant and persistent challenge to quality control in the compounding industry.

References

- Gudeman, J. Jozwiakowski, M. Chollet, J. & Randell, M. (2013). Potential Risks of Pharmacy Compounding. Drugs in R&D, 13(1), 1 ∞ 8.

- United States Pharmacopeial Convention. (2019). General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations. In United States Pharmacopeia and National Formulary (USP 42-NF 37).

- United States Pharmacopeial Convention. (2019). General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations. In United States Pharmacopeia and National Formulary (USP 42-NF 37).

- U.S. Food and Drug Administration. (2018). Current Good Manufacturing Practice ∞ Guidance for Human Drug Compounding Outsourcing Facilities Under Section 503B of the FD&C Act.

- The National Academies of Sciences, Engineering, and Medicine. (2020). The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of the Evidence. The National Academies Press.

- Glass, G. (2020). Analytical Testing for Compounded BHRT Products. Presentation to the National Academies of Sciences, Engineering, and Medicine.

- Kastango, E. S. & Bradshaw, B. D. (2014). USP Chapter 797 ∞ Historical perspective and future vision. International Journal of Pharmaceutical Compounding, 18(1), 31-36.

- Tanne, J. H. (2012). Contaminated steroid injections lead to meningitis outbreak in US. BMJ, 345, e6810.

- McPherson, T. Fontane, P. Jackson, K. & Martin, J. (2016). Quality-assurance practices in compounding pharmacies. Journal of the American Pharmacists Association, 56(4), 419-425.e1.

- Santoveña, A. Llabrés, M. & Fariña, J. B. (2015). Quality control of compounded medicines. Farmacia Hospitalaria, 39(S1), 33-42.

Reflection

You began this exploration seeking to understand your body and reclaim your sense of well-being. The knowledge you have gained about the world of compounding pharmacy is another tool in your personal health toolkit. It transforms you from a passive recipient of care into an active, informed partner in your own health journey.

The path to optimal hormonal and metabolic function is built on a foundation of precision and trust. Your willingness to ask questions and expect transparency is not a challenge to the system; it is a vital contribution to its integrity. Consider how you will use this understanding to engage with your clinical team, ensuring that the personalized care you seek is supported by the quality you deserve.