Fundamentals

The decision to take control of your hormonal health is a significant step on your personal wellness journey. It often begins with a deep, intuitive sense that your body’s internal communication system is functioning at a suboptimal level.

You may feel a pervasive fatigue that sleep does not resolve, a shift in your mood or cognitive clarity, or a general decline in vitality that affects your quality of life.

When you and your clinician decide on a protocol, whether it involves bioidentical hormones or therapeutic peptides, a new and valid concern arises ∞ how can you be certain that the substance you are introducing into your body is precisely what it claims to be, both in its identity and its purity?

This question is rooted in the complex reality of our modern pharmaceutical supply chain. The active pharmaceutical ingredients (APIs) at the core of many therapies are often synthesized in facilities across the globe. This international network allows for efficient production, but it also creates a long and complex chain of custody between the manufacturing of a raw material and the moment you administer your prescribed therapy.

Each step in this chain introduces a potential point of vulnerability for contamination, degradation, or inaccurate dosing. Your concern for purity is therefore a rational and essential component of responsible health management. It reflects an understanding that the efficacy and safety of any protocol depend entirely on the quality of the therapeutic agent itself.

Third-party testing provides an independent verification of a product’s chemical identity, its strength, and its freedom from common contaminants.

Understanding the Role of Independent Verification

In this landscape, third-party testing emerges as a critical instrument for quality assurance. This process involves sending a sample of a finished product to an independent, accredited laboratory that has no affiliation with the original manufacturer or the final distributor. The purpose of this external analysis is to receive an unbiased, scientific assessment of the product’s contents. The laboratory performs a series of sophisticated tests to answer three fundamental questions.

- Identity ∞ Does the product contain the correct active ingredient? Sophisticated analytical techniques are used to confirm that the molecular structure of the substance matches the reference standard for the prescribed hormone or peptide.

- Potency ∞ Does the product contain the correct amount of the active ingredient? The concentration of the API is measured to ensure it aligns with the dosage specified on the label. This is vital, as both under-dosing and over-dosing can undermine therapeutic goals and introduce health risks.

- Purity ∞ Is the product free from harmful contaminants? The sample is screened for a range of undesirable substances, which can include heavy metals, residual solvents from the manufacturing process, and microbial contaminants like bacteria or fungi.

This verification process functions as an essential layer of protection. It provides a scientifically validated certificate of analysis (CoA) that confirms the quality of a specific batch. For both patients and clinicians, a credible CoA from a reputable third-party lab offers a degree of confidence that the product meets established quality standards.

The Foundation of Quality Good Manufacturing Practices

Third-party testing does not occur in a vacuum. It validates a product against a pre-existing set of standards known as Good Manufacturing Practices (GMP). GMP is a globally recognized regulatory framework enforced by agencies like the U.S. Food and Drug Administration (FDA) and the World Health Organization (WHO). These guidelines establish the minimum requirements for every aspect of pharmaceutical production, including facility cleanliness, equipment calibration, personnel training, raw material sourcing, and process documentation.

A manufacturer that adheres to GMP is committed to building quality into its products from the ground up. These practices are designed to prevent contamination and ensure consistency from one batch to the next.

When a third-party lab tests a product, it is essentially verifying that the manufacturer’s GMP-compliant processes have resulted in a final product that meets the required specifications for identity, potency, and purity. The testing provides a snapshot of the quality of the end product, while GMP represents the ongoing, systemic commitment to quality throughout the entire manufacturing process.

Intermediate

Advancing from a foundational understanding of third-party testing requires a closer examination of the specific scientific methods employed and the systemic vulnerabilities they are designed to address. The journey of a therapeutic compound from a chemical precursor to a sterile vial is one of precision chemistry and industrial scale.

At each stage, opportunities for deviation exist. An independent laboratory acts as a crucial checkpoint, using an arsenal of analytical technologies to peer into the molecular composition of the final product and ensure it aligns with clinical expectations.

The trust you place in a hormone or peptide therapy is ultimately trust in its molecular integrity. For a man on a Testosterone Replacement Therapy (TRT) protocol, confidence is knowing that each injection delivers a precise dose of Testosterone Cypionate, free from industrial solvents or bacterial endotoxins that could provoke an inflammatory response.

For a woman using a compounded bioidentical hormone cream, it is the assurance that the preparation contains the specified amounts of estradiol and progesterone, without contaminants that could disrupt her endocrine balance. The work of the analytical laboratory provides the data that underpins this confidence.

The Analytical Toolkit a Deeper Look at Testing Methods

An accredited third-party laboratory utilizes a suite of sophisticated instruments to conduct its analysis. Each machine is designed to answer a specific question about the product’s composition. These methods are the gold standard in analytical chemistry, providing highly accurate and reproducible results.

High-Performance Liquid Chromatography (HPLC)

HPLC is the workhorse for determining both identity and potency. The process begins by dissolving the product sample in a solvent to create a liquid solution. This solution is then injected into the HPLC system and pushed through a column packed with a solid adsorbent material.

Different molecules travel through the column at different speeds based on their chemical properties. A detector at the end of the column records the precise time each component emerges, creating a chromatogram with distinct peaks. By comparing the peak of the active ingredient to that of a certified reference standard, the lab can confirm its identity.

The area under the peak is proportional to the concentration of the substance, allowing for a precise quantification of its potency. This ensures the product is as strong as the label claims.

Mass Spectrometry (MS)

Often coupled with chromatography (GC-MS or LC-MS), mass spectrometry provides an even more definitive confirmation of molecular identity and can detect impurities. After molecules are separated by the chromatograph, they enter the mass spectrometer, where they are ionized and broken into charged fragments.

The instrument then measures the mass-to-charge ratio of these fragments, generating a unique molecular fingerprint. This fingerprint is compared against a library of known compounds to confirm the identity of the API and to identify any unknown peaks that may represent contaminants or degradation byproducts.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

When the concern is contamination with heavy metals, ICP-MS is the premier analytical method. The product sample is introduced into a high-temperature plasma, which atomizes the sample and ionizes the elements within it. These ions are then passed into a mass spectrometer, which can detect and quantify specific metals down to parts per billion or even parts per trillion.

This extreme sensitivity is crucial for identifying toxic metals like lead, mercury, arsenic, and cadmium, which can pose health risks even at trace levels. These metals can be introduced from raw materials, manufacturing equipment, or environmental sources.

The Certificate of Analysis translates complex analytical data into a clear statement on a product batch’s adherence to quality standards.

What Are the Blind Spots in Standard Testing Panels?

While comprehensive, standard third-party testing panels have inherent limitations. The testing process is targeted; it looks for a specific list of known compounds and contaminants. This creates potential blind spots for substances that fall outside of a typical screening panel.

A standard purity test will identify residual solvents used in common chemical syntheses, but it may not detect a novel or unexpected byproduct of a poorly executed synthesis. Similarly, a standard microbial test looks for common bacteria and molds, but it might not be designed to find more exotic contaminants.

Furthermore, testing addresses the product, not the packaging. Issues like the leaching of chemicals from vials or stoppers can occur after the product has been tested and packaged. The table below outlines the primary focus of key testing methodologies and the corresponding areas where risks may persist.

| Testing Methodology | Primary Analytical Target | Potential Blind Spot or Limitation |

|---|---|---|

|

Identity and Potency of Active Ingredient |

Does not identify unknown impurities that have different chemical properties. |

|

|

Gas Chromatography-Mass Spectrometry (GC-MS) |

Volatile Organic Compounds, Solvents, Impurities |

Ineffective for non-volatile contaminants like heavy metals or complex proteins. |

|

Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) |

Provides no information on organic or microbial contaminants. |

|

|

Microbial Enumeration & Endotoxin Testing |

Presence of Bacteria, Yeast, Mold, and Endotoxins |

Cannot detect viral particles or prions; reflects sterility at time of testing only. |

The Compounded Therapy Dilemma

The challenge of ensuring purity is particularly relevant for compounded therapies, including many bioidentical hormone preparations. Unlike FDA-approved drugs produced in large, standardized batches, compounded medications are often prepared in smaller quantities for individual patients. While compounding pharmacies are subject to state and federal regulation, the consistency and quality control can vary.

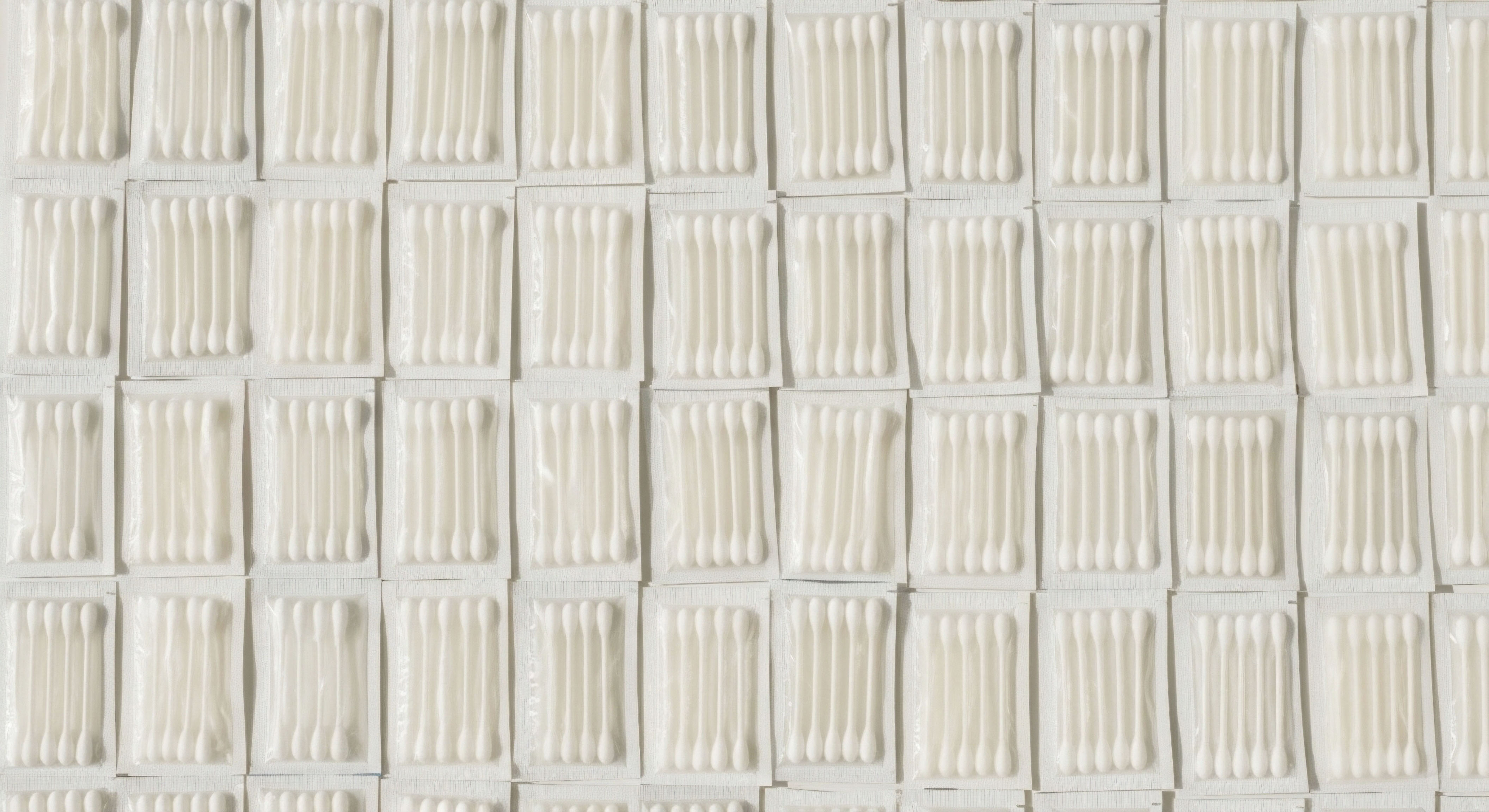

The APIs used by compounding pharmacies are frequently sourced from international suppliers. A conscientious compounding pharmacy will quarantine and test these raw materials before using them in patient formulations. This initial testing of the API is a critical step.

Following that, the pharmacy must ensure its own compounding process is sterile and precise to prevent contamination or inaccurate dosing in the final preparation. The most diligent compounding pharmacies will go a step further, sending samples of their finished products for third-party testing to validate their in-house processes. This multi-layered approach to quality control is a hallmark of a trustworthy compounding pharmacy.

Academic

A sophisticated analysis of the global pharmaceutical supply chain reveals that third-party testing, while an indispensable tool for quality verification, functions as a downstream intervention in a system with deeply embedded, upstream vulnerabilities. Its capacity to fully mitigate purity concerns is constrained by the very structure of international manufacturing and distribution.

The process of testing a single sample from a finished batch provides a high-resolution snapshot of quality at a specific point in time. It cannot, however, fully account for the dynamic and varied risks inherent in a system characterized by long supply chains, fragmented regulatory oversight, and powerful economic pressures that can compromise quality at the source.

The fundamental challenge lies in the distinction between verifying a product and validating a process. Third-party testing excels at the former. The larger, more complex issue is ensuring the integrity of the entire manufacturing continuum, from the synthesis of the first molecule of an active pharmaceutical ingredient (API) to its final formulation and packaging.

The globalization of API manufacturing, with a heavy concentration in countries like China and India, has created a system where economic efficiency can be at odds with a robust quality culture. This dynamic places a significant burden on downstream quality control measures.

The Statistical Limitations of Batch Testing

The practice of batch testing is predicated on the assumption that the tested sample is representative of the entire batch. In a well-controlled process operating under stringent Good Manufacturing Practices (GMP), this is a reasonable assumption. Contamination or deviation, however, is often a non-uniform event.

A localized microbial contamination in one part of a reactor or a “hot spot” of residual solvent may not be homogenously distributed throughout the entire batch. A randomly selected sample could therefore miss such an anomaly.

This statistical limitation means that a clean Certificate of Analysis (CoA) reduces the probability of a quality issue to a very low level; it does not eliminate it entirely. The confidence provided by a CoA is proportional to the quality of the underlying manufacturing process.

If the manufacturer adheres strictly to GMP, the batch is likely to be uniform, and the sample is likely to be representative. If the manufacturing process is inconsistent, the value of a single-sample test diminishes. This is why regulators and quality experts focus so heavily on the validation of the manufacturing process itself, including ongoing monitoring and control of critical process parameters.

The Challenge of Novel Contaminants and Economic Adulteration

Standard analytical panels are designed to detect known risks. They are built around the expected impurities of a given synthesis route, common environmental contaminants, and typical microbial flora. The system is less prepared for novel or unexpected contaminants. A manufacturer using a new, unvalidated synthesis pathway to cut costs might generate byproducts that are not included in standard screening libraries. These “unknown unknowns” can pass through a typical testing regimen undetected.

A more pernicious issue is intentional economic adulteration. In this scenario, a substance is deliberately added to a raw material or API to mimic the properties of the genuine material on a simple test, while reducing the manufacturer’s cost. The 2008 heparin contamination event serves as a stark case study.

A cheaper, oversulfated chondroitin sulfate was intentionally added to raw heparin sourced from China. This adulterant was designed to evade standard identity tests but caused severe allergic reactions and fatalities. Detecting such sophisticated adulterants requires the development and deployment of highly specific, advanced analytical methods that may not be part of a routine testing protocol. This illustrates a critical point ∞ third-party testing is often reacting to past failures rather than proactively identifying all potential future risks.

| Risk Category | Description | Example | Limitation of Standard Testing |

|---|---|---|---|

|

Process-Related Impurities |

Substances generated during the chemical synthesis of the API. |

Residual solvents, unreacted starting materials, atypical byproducts. |

May not detect novel impurities from unvalidated synthesis routes. |

|

Contamination Events |

Introduction of external substances during or after manufacturing. |

Microbial ingress, heavy metals from equipment, cleaning agent residue. |

Testing is statistical; may miss non-uniform contamination within a batch. |

|

Economic Adulteration |

Intentional substitution or addition of a cheaper substance. |

Melamine in milk protein, oversulfated chondroitin sulfate in heparin. |

Requires highly specific, advanced methods that may not be in routine panels. |

|

Degradation Products |

Impurities formed by the breakdown of the API due to heat, light, or time. |

Formation of less potent or potentially toxic related substances. |

A CoA reflects purity at the time of testing, not after improper storage or shipping. |

How Can the Integrity of the Global Supply Chain Be Fortified?

Addressing the root causes of international purity concerns requires a multi-layered strategy that extends beyond downstream product testing. While third-party testing remains a vital component, it should be viewed as one part of a more comprehensive quality assurance ecosystem.

- Harmonization and Enforcement of GMP ∞ Strengthening international agreements and conducting rigorous, unannounced inspections of overseas API manufacturers are foundational steps. Ensuring that global manufacturers adhere to the same high GMP standards reduces the likelihood of quality issues at the source.

- Supply Chain Transparency and Traceability ∞ The implementation of technologies like blockchain can create an immutable ledger that tracks an API from its origin to the final pharmacy. This enhances accountability and makes it more difficult for counterfeit or contaminated products to enter the legitimate supply chain.

- Advanced Analytical Surveillance ∞ Regulatory agencies and independent labs must move toward a more proactive posture, developing and deploying advanced analytical techniques to screen for a wider range of potential adulterants, beyond the standard panels. This includes building libraries of potential impurities from known alternative manufacturing processes.

- Supplier Qualification Programs ∞ Pharmacies and manufacturers must implement extremely rigorous supplier qualification programs. This involves not just testing the incoming API but also auditing the manufacturer’s facility, reviewing their process validation data, and assessing their overall quality culture.

Ultimately, third-party testing serves as an essential verification mechanism. It provides the best available assurance for a specific product batch. Its capacity to fully resolve all international purity concerns is limited by the systemic and dynamic nature of the risks involved. True mitigation is achieved when this critical downstream check is integrated into a robust, proactive, and transparent global quality system that builds integrity into the product from its inception.

References

- World Health Organization. (2018). WHO good manufacturing practices for pharmaceutical products ∞ main principles. WHO Technical Report Series, No. 908, Annex 4.

- U.S. Food and Drug Administration. (2007). CFR – Code of Federal Regulations Title 21, Part 111 ∞ Current Good Manufacturing Practice in Manufacturing, Packaging, Labeling, or Holding Operations for Dietary Supplements.

- National Academies of Sciences, Engineering, and Medicine. (2020). The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of Safety, Effectiveness, and Use. The National Academies Press.

- Plumb, J. J. (2015). Heavy Metals in Drug Products. Contract Pharma.

- European Medicines Agency. (2022). Good manufacturing practice for medicinal products for human and veterinary use. EudraLex, Volume 4.

- Univera. (2025). Why GMP Certification and Third-Party Testing Are Crucial in Dietary Supplements.

- Taylor, D. (2015). The Pharmaceutical Supply Chain ∞ A Five-Step Plan for Improvement. Pharmaceutical Technology, 39(10).

- World Health Organization & United Nations Office on Drugs and Crime. (2025). Contaminated medicines and integrity of the pharmaceutical excipients supply chain.

- Chi, L. et al. (2017). Arsenic exposure in association with gut microbiome. Environmental Health Perspectives, 125(3), 474-481.

- The Endocrine Society. (2016). Compounded Bioidentical Hormones in Endocrinology Practice ∞ An Endocrine Society Scientific Statement. Journal of Clinical Endocrinology & Metabolism, 101(4), 1318 ∞ 1343.

Reflection

The information presented here provides a map of a complex global system, complete with its safeguards and its inherent fractures. Understanding the science of verification, from HPLC to ICP-MS, and the systemic challenges of a worldwide supply chain, moves you to a new position in your health journey.

You are now equipped with a more sophisticated framework for evaluating the quality of the therapies you consider. This knowledge is the foundation for a deeper, more collaborative dialogue with your clinician.

Your path to optimized health is deeply personal. The decision to use a specific therapy is based on your unique biology, symptoms, and goals. The choice of where to source that therapy should be made with an equal level of personalized diligence.

The question now becomes ∞ How does this understanding of purity, testing, and systemic risk inform your choices? It prompts a shift in focus toward the quality systems of the pharmacies you work with and the transparency they offer. Your journey is one of reclaiming biological function, and that process begins with a profound commitment to the quality and integrity of the very tools you use to do so.