Fundamentals

The desire for hormonal equilibrium is a deeply personal and valid pursuit. When you experience the pervasive symptoms of hormonal shifts ∞ the fatigue that settles deep in your bones, the cognitive fog that clouds your thoughts, or the emotional lability that disrupts your sense of self ∞ the goal is to find a stable, predictable path back to vitality.

You seek a therapeutic protocol that delivers not just a hormone, but a consistent, reliable biological message. This very consistency is the bedrock upon which hormonal wellness is built. The central question then becomes one of trust in the therapeutic agent itself. Can a preparation created for you, and you alone, deliver the unwavering potency required to restore your body’s intricate signaling systems?

Understanding potency begins with appreciating the body’s sensitivity to hormonal messengers. Hormones operate within a precise therapeutic window, a range where the concentration is high enough to elicit the desired physiological effect but low enough to avoid unwanted side effects.

A preparation with inconsistent potency can cause your hormone levels to oscillate, dipping below this window one day and soaring above it the next. This biochemical variability can manifest as a frustrating return of symptoms or the emergence of new, undesirable effects.

The feeling of well-being becomes fleeting, and the journey toward balance feels like a series of false starts. True hormonal optimization depends on a steady, physiological state, which can only be achieved when the potency of each dose is assured.

What Is Pharmaceutical Compounding

Pharmaceutical compounding is the art and science of creating a personalized medication for an individual patient. A licensed pharmacist or physician combines, mixes, or alters ingredients in response to a prescription to create a medication tailored to the specific needs of a patient.

This practice can provide essential therapeutic alternatives for individuals who cannot be treated with commercially available, mass-produced medications. For example, compounding is necessary for a patient who has a documented allergy to an inactive ingredient, such as a dye or preservative, found in an FDA-approved product.

It also serves patients, often children or the elderly, who require a specific dosage strength that is not manufactured or who need the medication in a different form, such as a liquid instead of a solid tablet.

The process begins with a prescription from a healthcare provider that specifies the active pharmaceutical ingredients (APIs), the dosage form, the strength, and the route of administration. The compounding pharmacist then prepares the medication according to these specifications. This practice allows for a high degree of customization, which is its primary clinical justification.

Bioidentical hormones, which are molecules with a chemical structure identical to the hormones produced by the human body, are frequently used in these preparations. The goal is to provide a hormonal therapy that precisely matches the patient’s prescribed needs, a concept that is powerfully appealing to anyone seeking a tailored approach to their health.

The Promise of Individualization

The appeal of individualized compounding lies in its potential to move beyond a one-size-fits-all model of care. For hormonal health, this is particularly resonant. Your unique physiology, metabolic rate, and symptom profile suggest that your therapeutic needs are also unique.

The promise is that a compounded preparation can be adjusted by fractions of a milligram, or combined in specific ratios ∞ such as Bi-est (estriol and estradiol) or Tri-est (estriol, estradiol, and estrone) ∞ to match your specific biological requirements. This level of personalization fosters a sense of partnership in your own care, empowering you with a treatment plan that appears to be designed exclusively for your body.

This approach aligns with the broader movement toward personalized medicine, where treatments are increasingly tailored to the individual. In the context of hormonal therapy, this means creating a preparation that theoretically provides only what is needed, in the exact amount needed, to restore a state of balance.

The focus is on precision, with the ultimate goal of achieving consistent symptom relief and enhanced well-being without compromise. The fundamental assumption is that this bespoke creation process can be executed with the same degree of accuracy and reproducibility dose after dose, month after month. The integrity of this assumption is the central issue in determining the reliability of compounded preparations.

Intermediate

Achieving consistent potency in a compounded bioidentical hormone preparation is a complex endeavor, contingent upon a multitude of factors that extend from the raw ingredients to the final formulation. Unlike the standardized, rigorously controlled environment of large-scale pharmaceutical manufacturing, compounding introduces variables at nearly every step of the process.

The question of consistent potency is therefore a question of how well these variables can be controlled within the framework of a compounding pharmacy. The answer directly impacts the predictability of the therapeutic outcome and the stability of your physiological response. To understand this, one must examine the critical junctures in the compounding process where potency can be influenced.

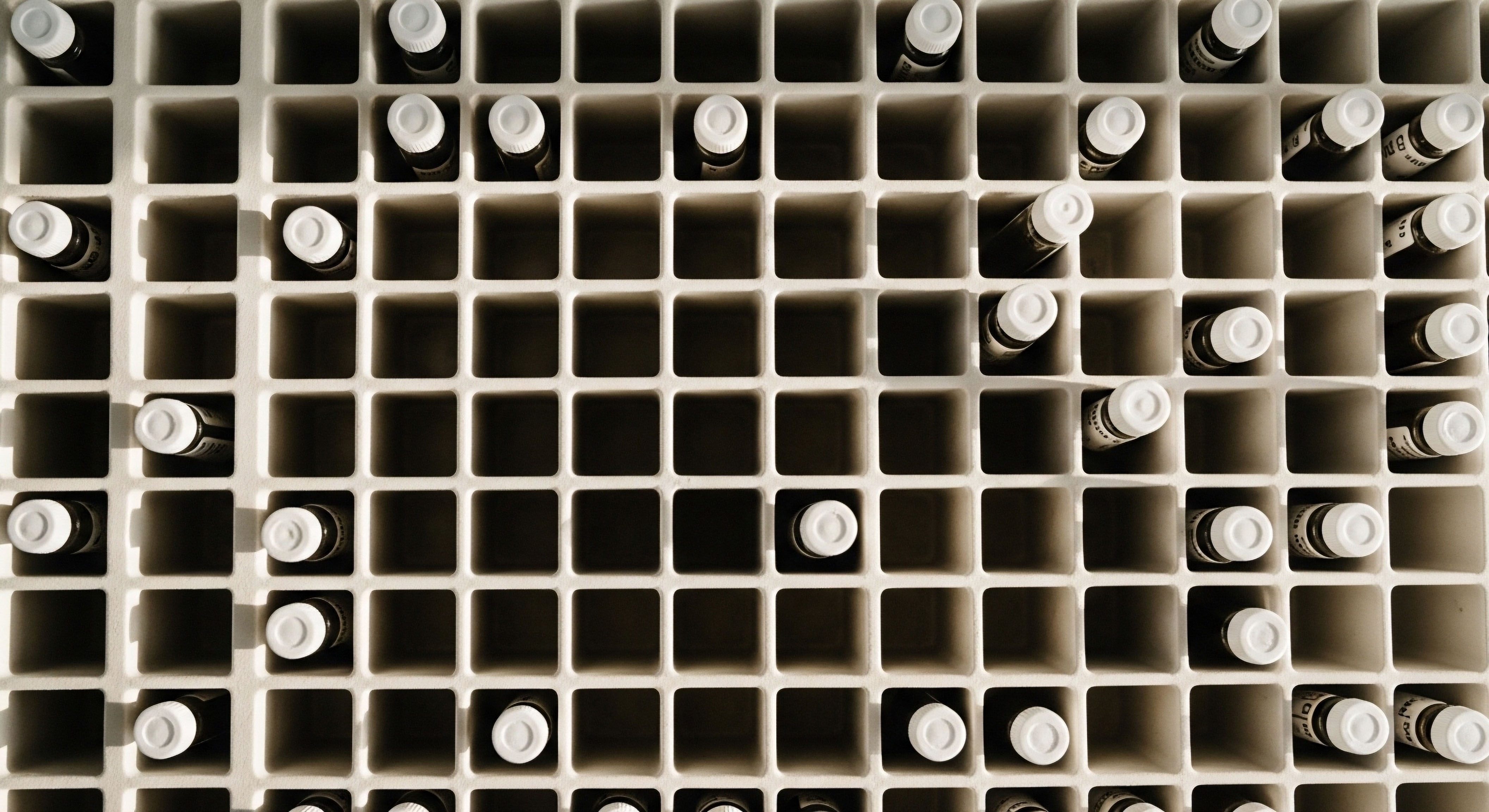

The journey from prescription to final product involves sourcing APIs, selecting a base or vehicle (such as a cream or gel), meticulously measuring and mixing ingredients, and packaging the final preparation. Each of these stages presents a potential for variability.

The quality and physical characteristics of the hormone powder itself, the precision of the pharmacist’s technique, the calibration of the equipment, and the chemical interactions within the final mixture all contribute to the final potency.

A lack of stringent, universally enforced standards for each of these elements means that two preparations, made from the identical prescription but at different pharmacies or even by different pharmacists at the same location, may not be interchangeable. This introduces an element of uncertainty into a therapeutic process that is designed to deliver stability.

The consistency of a compounded hormone preparation is a direct function of the quality control applied to its raw materials and formulation process.

Sources of Potency Variation in Compounded Hormones

The potency of a final compounded hormone preparation is not a single, guaranteed property but the result of a multi-step process where precision is paramount. Variability can be introduced at several points, each capable of altering the concentration of the active hormone that is ultimately delivered to your body. Understanding these sources of variation is essential to appreciating the challenges involved in ensuring dose-to-dose consistency.

Active Pharmaceutical Ingredient Quality

The foundation of any compounded preparation is the active pharmaceutical ingredient, or the raw hormone powder. The quality of this API is a primary determinant of the final product’s potency. Several characteristics of the API itself can introduce variability:

- Purity ∞ The certificate of analysis provided by a supplier states the purity of the API, but this may not always reflect the reality upon receipt at the pharmacy. Without independent verification testing, which is not standard practice in all compounding settings, there is a reliance on the supplier’s data. Impurities can displace the active hormone, effectively lowering the potency of the final preparation.

- Particle Size ∞ For hormones delivered in creams, gels, or capsules, particle size is a critical factor. Micronized hormones, which have been milled into very fine particles, have a larger surface area, which generally enhances their solubility and absorption. Inconsistent or non-uniform particle size between different batches of API can lead to significant differences in bioavailability, meaning that even if the concentration of the hormone in the cream is correct, the amount that your body can actually absorb and use may fluctuate.

- Polymorphism ∞ Some hormone powders can exist in different crystalline structures, known as polymorphs. Each polymorph can have a different solubility and dissolution rate, which in turn affects how the hormone is absorbed. A change in the polymorphic form of the API from one batch to the next can result in a final product with a different therapeutic profile, even if all other aspects of the compounding process remain the same.

The Compounding Process Itself

The pharmacist’s technique and the pharmacy’s environment are central to the consistency of the final product. The process is far more complex than simply mixing ingredients; it is a precise scientific procedure where small deviations can have meaningful consequences. Key process-related factors include:

- Equipment and Calibration ∞ The accuracy of electronic balances, electronic mortars and pestles, and ointment mills is fundamental. If this equipment is not regularly and properly calibrated, the measurements of both the API and the base can be inaccurate, leading directly to a sub-potent or super-potent final product.

- Mixing Technique ∞ The method used to incorporate the hormone powder into the base is critical for ensuring a uniform distribution. Inadequate mixing can result in “hot spots” where the hormone is highly concentrated and other areas where it is sparse. This lack of content uniformity means that one application from the container may deliver a much higher or lower dose than the next. The order in which ingredients are added and the duration of mixing can also impact the stability and homogeneity of the preparation.

- Environmental Controls ∞ Factors such as temperature and humidity within the pharmacy can affect the stability of both the raw APIs and the final compounded preparation. Degradation of the hormone can occur if it is exposed to improper conditions, leading to a loss of potency over time.

Regulatory and Quality Standards a Comparison

The regulatory frameworks governing compounded hormones and FDA-approved manufactured hormones are fundamentally different, leading to significant disparities in how potency and consistency are ensured. FDA-approved drugs are subject to the Current Good Manufacturing Practices (CGMP), a comprehensive set of regulations that enforce rigorous quality control at every stage of production.

Compounding pharmacies, by contrast, are primarily regulated by state boards of pharmacy and are expected to follow standards set by the United States Pharmacopeia (USP), which are less stringent than CGMP.

| Feature | USP Standards for Compounding (503A Pharmacies) | FDA Current Good Manufacturing Practices (CGMP) |

|---|---|---|

| Regulatory Oversight | Primarily regulated by state boards of pharmacy; oversight and enforcement vary by state. | Regulated directly by the FDA with routine, risk-based inspections. |

| Ingredient Validation | Pharmacists may rely on a supplier’s certificate of analysis for ingredient identity and purity. Independent testing is not universally required. | Manufacturers must conduct independent, thorough testing of all raw materials and components to confirm identity, purity, and quality. |

| Process Validation | The compounding process for a specific formulation is not required to undergo formal validation to ensure it consistently produces a product of a certain quality. | Manufacturing processes must be rigorously validated to prove they are robust and consistently yield a product that meets all quality specifications. |

| Finished Product Testing | Potency testing of the final product is not required for every batch. Quality control may be limited to visual inspection and checking for weight variation. | Every batch of a finished drug product must be tested for potency, purity, and other quality attributes before it can be released for distribution. |

| Stability Testing | Beyond-use dates (BUDs) are assigned based on USP guidelines, which are often based on general data for similar preparations, not product-specific stability studies. | Manufacturers must conduct extensive, real-time stability studies on their specific drug product in its final packaging to establish a scientifically-backed expiration date. |

This comparison illustrates the structural differences in quality assurance. CGMP is designed to ensure that every single tablet or dose of a medication is identical to the next, through a system of mandatory validation and testing. USP standards provide a framework for good compounding practices but do not require the same level of objective, data-driven proof of consistency for each preparation. This gap is central to the question of whether individualized compounding can ensure consistent potency.

Academic

The assurance of consistent potency in compounded bioidentical hormone therapy is fundamentally an issue of analytical chemistry, pharmaceutical science, and regulatory science. From an academic perspective, the question transcends simple adherence to procedural guidelines and enters the domain of pharmacokinetics, pharmacodynamics, and the quantifiable metrics of quality control.

The clinical utility of any hormonal protocol is predicated on its ability to establish and maintain serum hormone concentrations within a specific therapeutic range. Significant deviations from this range, resulting from inconsistent potency, can disrupt the delicate feedback mechanisms of the endocrine system, such as the Hypothalamic-Pituitary-Gonadal (HPG) axis, leading to unpredictable clinical outcomes and potential adverse events.

The core of the academic inquiry is whether the current framework for pharmaceutical compounding is equipped to manage the inherent chemical and physical complexities of hormone preparations to a degree that ensures therapeutic equivalence from batch to batch.

The challenge is magnified by the physicochemical properties of steroid hormones themselves. These molecules are typically lipophilic and have poor aqueous solubility, making their uniform dispersion in common topical bases like creams and gels a significant formulation challenge.

Factors such as particle size distribution, crystalline structure (polymorphism), and the potential for the API to recrystallize within the vehicle over time can profoundly impact the drug release profile and subsequent bioavailability.

In the absence of the rigorous process validation and finished product testing mandated by the FDA’s Current Good Manufacturing Practices (CGMP), the potential for batch-to-batch and even intra-batch variability in compounded preparations is substantial. A comprehensive analysis, therefore, requires an examination of the analytical methods available for potency determination, the documented evidence of potency variability in compounded hormones, and the physiological consequences of such inconsistencies.

Pharmacokinetic stability is the ultimate measure of consistent potency, as it reflects the actual concentration of the hormone available to interact with target tissues over time.

Pharmacokinetic Implications of Inconsistent Potency

The therapeutic effect of a hormone is directly related to its concentration at the receptor site, a state governed by the principles of pharmacokinetics ∞ absorption, distribution, metabolism, and excretion (ADME). Inconsistent potency in a compounded preparation introduces profound uncertainty into this process, making it difficult, if not impossible, to achieve a predictable and stable pharmacokinetic profile.

A dose that is super-potent can lead to supraphysiological serum levels, while a sub-potent dose may fail to reach the minimum effective concentration.

For example, a patient using a transdermal testosterone cream relies on a consistent release of the hormone from the cream base, followed by absorption through the skin to maintain steady serum levels. If one batch of cream has a higher-than-intended potency or a formulation that enhances penetration, the patient may experience transiently high testosterone levels.

This could lead to androgenic side effects such as acne or irritability. Conversely, a subsequent batch that is sub-potent could cause a precipitous drop in serum levels, leading to a re-emergence of symptoms like fatigue and low libido.

This pharmacokinetic rollercoaster prevents the body from adapting to a stable hormonal milieu, which is the very goal of the therapy. The National Academies of Sciences, Engineering, and Medicine report highlights these concerns, noting that the lack of bioavailability data for cBHT preparations raises questions about their safety and the reproducibility of their intended physiological effects.

How Does Potency Affect the Hypothalamic Pituitary Gonadal Axis?

The HPG axis is a classic example of a negative feedback loop that regulates the production of sex hormones. In men, for instance, the hypothalamus releases Gonadotropin-Releasing Hormone (GnRH), which signals the pituitary to release Luteinizing Hormone (LH). LH then travels to the testes, stimulating the production of testosterone.

As testosterone levels rise, they send a signal back to the hypothalamus and pituitary to decrease the production of GnRH and LH, thus maintaining homeostasis. When exogenous testosterone is administered as part of a TRT protocol, this feedback loop is suppressed.

Inconsistent potency can wreak havoc on this sensitive system. A super-potent dose of compounded testosterone can cause profound suppression of the HPG axis, shutting down endogenous production almost completely. If the next batch is sub-potent, the exogenous supply is suddenly insufficient, but the HPG axis remains suppressed and cannot immediately compensate for the deficit.

This can lead to a period of acute hypogonadism, with a pronounced return of symptoms. To mitigate this testicular suppression, TRT protocols often include agents like Gonadorelin, which mimics GnRH to maintain the signaling pathway to the testes. However, the effectiveness of such adjunctive therapies is also predicated on a stable and predictable level of exogenous testosterone. Potency fluctuations complicate the management of the entire endocrine system, turning a protocol designed for balance into a source of systemic disruption.

Analytical Methods for Potency Verification

The definitive determination of potency requires sophisticated analytical chemistry techniques. The gold standard for quantifying small molecules like steroid hormones in a complex matrix (such as a cream or a biological fluid) is High-Performance Liquid Chromatography coupled with Tandem Mass Spectrometry (HPLC-MS/MS). This method offers exceptional specificity and sensitivity, allowing for the precise identification and quantification of the active hormone, distinguishing it from any excipients, impurities, or degradation products.

The process involves several steps:

- Sample Preparation ∞ A precise amount of the compounded preparation is weighed and dissolved in a series of solvents to extract the hormone from the base matrix. This step is critical and must be carefully validated to ensure complete extraction.

- Chromatographic Separation ∞ The extract is injected into the HPLC system. The liquid chromatograph uses a high-pressure pump to pass the sample through a column packed with a special material. Different molecules travel through the column at different speeds based on their chemical properties, effectively separating the hormone from other components.

- Mass Spectrometric Detection ∞ As the separated components exit the column, they enter the mass spectrometer. Here, they are ionized (given an electrical charge) and then separated based on their mass-to-charge ratio. A tandem mass spectrometer (MS/MS) provides an additional layer of specificity by selecting ions of a specific mass, fragmenting them, and then analyzing the resulting fragment ions. This process creates a unique chemical fingerprint for the target hormone, allowing for unambiguous identification and highly accurate quantification.

While such technology is the cornerstone of quality control in pharmaceutical manufacturing, its application in compounding pharmacies is not standard. The cost of the equipment, the need for highly trained personnel, and the absence of a regulatory mandate mean that routine end-product potency testing is rarely performed for preparations dispensed by traditional 503A compounding pharmacies. This operational reality is a primary reason why consistent potency cannot be guaranteed in the same way it is for manufactured products.

| Aspect | Compounded Preparations (Typical Practice) | FDA-Approved Manufactured Drugs |

|---|---|---|

| Methodology | Primarily procedural, relying on calculations, calibrated scales, and proper technique (process-based assurance). | Primarily analytical, relying on instrumental analysis of the finished product (results-based assurance). |

| Testing Frequency | Finished product testing is not required for each batch. | Every batch must be tested and confirmed to be within potency specifications before release. |

| Validation | The specific formulation process is not formally validated to ensure reproducibility. | The entire manufacturing process is rigorously validated to prove it consistently produces a quality product. |

| Data Availability | No public data are available on the potency of a specific compounded prescription. | Potency and stability data are submitted to and reviewed by the FDA as part of the drug approval process. |

The Endocrine Society and other major medical bodies have expressed concern over this lack of data, noting that inconsistencies in dose and quality have been uncovered in post-market surveys of compounded hormone preparations.

The National Academies report further states that there is a “substantial dearth of safety and efficacy data, including little or no high-quality pharmacokinetic data to inform evidence-based conclusions on the safety and effectiveness of cBHT preparations.” This lack of data is a direct consequence of the differences in the quality assurance paradigms between compounding and manufacturing.

References

- National Academies of Sciences, Engineering, and Medicine. The Clinical Utility of Compounded Bioidentical Hormone Therapy ∞ A Review of Safety, Effectiveness, and Use. The National Academies Press, 2020. https://doi.org/10.17226/25791.

- The Endocrine Society. “Compounded ‘Bioidentical’ Hormone Therapy (cBHT).” Position Statement, 2019.

- Files, J. A. et al. “Bioidentical hormone therapy ∞ An assessment of provider knowledge.” Maturitas, vol. 94, 2016, pp. 46-51.

- Stanczyk, F. Z. et al. “Determination of estradiol and progesterone content in capsules and creams from compounding pharmacies.” Menopause, vol. 26, no. 9, 2019, pp. 966-971.

- Gass, M. L. et al. “Use of compounded hormone therapy in the United States ∞ Report of The North American Menopause Society survey.” Menopause, vol. 22, no. 12, 2015, pp. 1276-1284.

- Sood, R. et al. “Bioidentical compounded hormones ∞ A pharmacokinetic evaluation in a randomized clinical trial.” Maturitas, vol. 74, no. 4, 2013, pp. 375-382.

- Grober, E. D. et al. “Accuracy of testosterone concentrations in compounded testosterone products.” The Journal of Sexual Medicine, vol. 12, no. 6, 2015, pp. 1381-1388.

- Thompson, J. J. et al. “Why women choose compounded bioidentical hormone therapy ∞ Lessons from a qualitative study of menopausal decision-making.” BMC Women’s Health, vol. 17, no. 1, 2017, p. 97.

Reflection

The information presented here provides a framework for understanding the complexities behind ensuring consistent hormonal potency. Your health journey is a dynamic process of learning, questioning, and making informed choices. The knowledge of how your therapies are created is a powerful tool, equipping you to engage in more meaningful conversations with your healthcare provider.

This understanding is the first step toward building a therapeutic alliance based on transparency and shared goals. The path to reclaiming your vitality is yours to navigate, and every piece of knowledge you acquire illuminates the way forward, allowing you to advocate for a standard of care that meets your needs for safety, predictability, and ultimately, well-being.

Glossary

pharmaceutical compounding

compounded bioidentical hormone

current good manufacturing practices

compounded hormones

compounding pharmacies

usp standards

compounded bioidentical hormone therapy

analytical chemistry

good manufacturing practices

finished product testing

pharmacokinetics

hpg axis

hplc-ms/ms