Fundamentals

You hold a small vial in your hand. It contains a fine, white powder, a substance that represents a significant step in your personal health protocol. This powder, a carefully synthesized peptide, is a key to unlocking a specific biological response, whether it is for metabolic recalibration, tissue repair, or hormonal optimization.

Before it can perform its function, it must be reconstituted. It must be brought back to life with a liquid, a process that seems simple yet holds a universe of biochemical importance. The question of how this peptide was formulated, and how the liquid you add will affect it, is central to its efficacy. Your body is a complex biological system, and the tools you use to support it deserve the same level of detailed understanding.

Peptides are sequences of amino acids, the fundamental building blocks of proteins. They act as precise biological messengers, signaling specific actions within your body’s intricate communication network. Think of them as keys designed to fit specific locks on your cells, initiating a cascade of events that can influence everything from your body’s inflammatory response to the production of essential hormones.

Because of their specific and powerful nature, they are also incredibly delicate. Their structure is their function, and that structure is fragile, susceptible to degradation from heat, agitation, and even time itself.

The stability of a therapeutic peptide is the foundation of its ability to work as intended within your body.

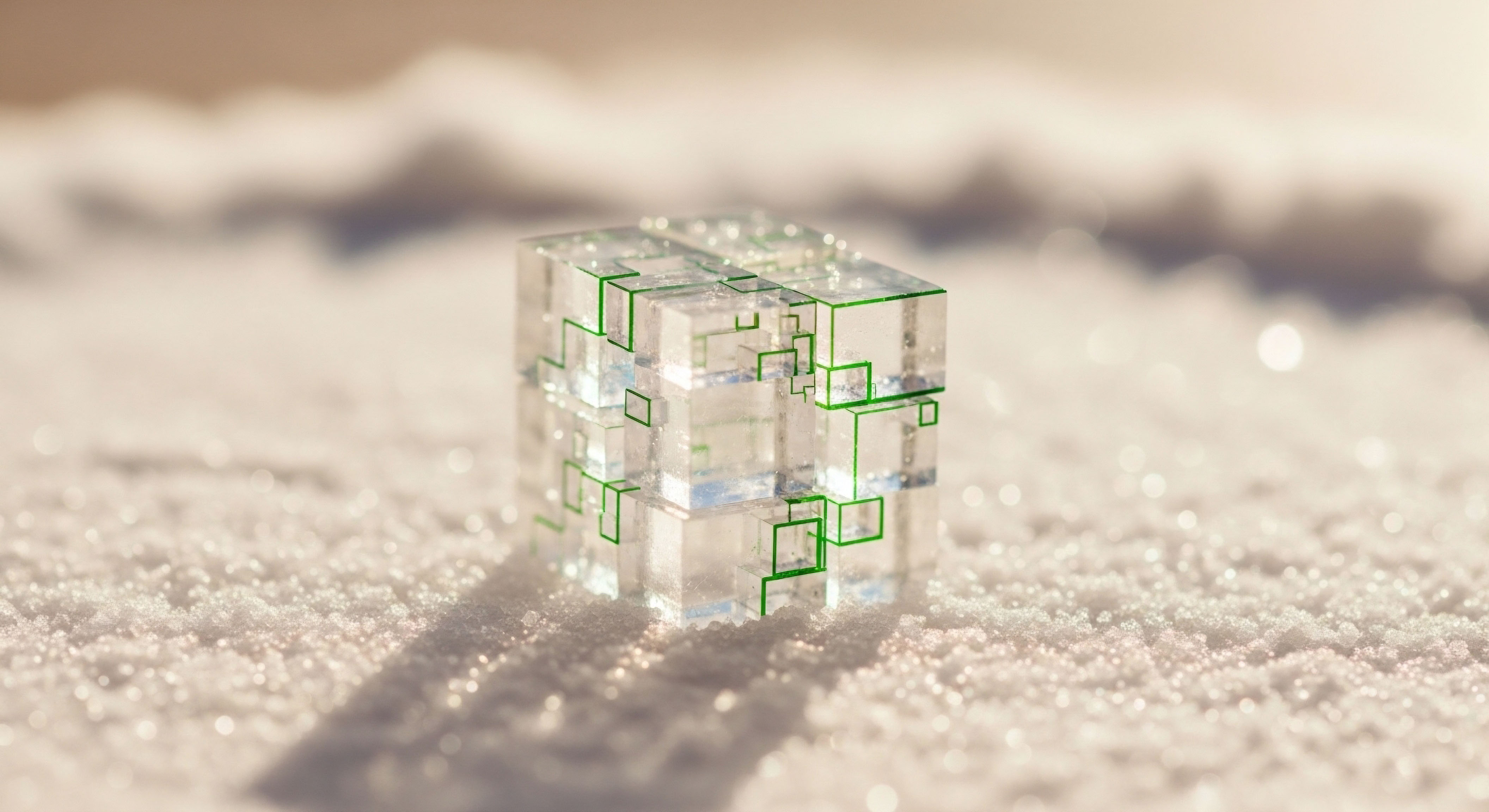

To protect these delicate molecules, they are often prepared through a process called lyophilization, or freeze-drying. This technique removes water under a deep vacuum while the peptide is frozen, transforming it into a stable, dry powder.

This powder is a marvel of pharmaceutical science, a peptide held in suspended animation, protected from the chemical reactions that would quickly degrade it in a liquid state. The lyophilized cake in the vial is more than just the peptide; it contains a supporting cast of compounds called excipients. These are non-medicinal substances that provide bulk, improve stability, and ensure the peptide can survive the freeze-drying process and long-term storage.

The Critical Moment of Reconstitution

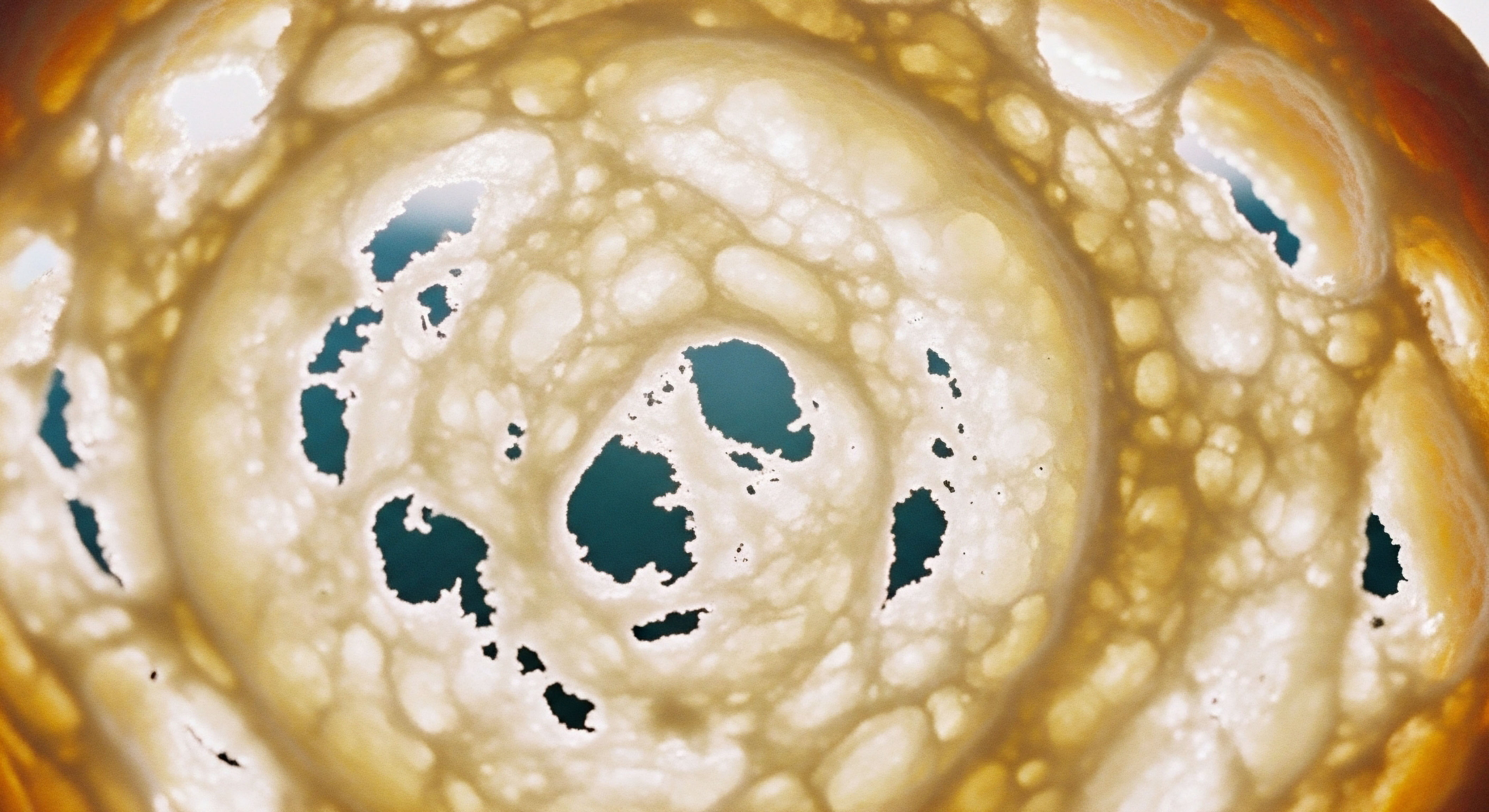

The moment you introduce a diluent ∞ the liquid used for mixing, such as bacteriostatic water ∞ is a critical transition. The peptide awakens from its preserved state and dissolves into a solution ready for administration. This is where the formulation science demonstrates its true importance.

The excipients that were freeze-dried alongside the peptide now have a new role ∞ to ensure the peptide remains stable and soluble in its new liquid environment. The composition of the diluent itself becomes a variable in this equation. The presence of a preservative like benzyl alcohol in bacteriostatic water, or the specific pH of the solution, can interact with the peptide and its accompanying excipients in profound ways.

Understanding this interaction is fundamental. It moves the conversation from simply following instructions to appreciating the science behind those instructions. Your personal wellness protocol is a series of precise inputs designed to create a desired biological output. The stability of your peptide is a non-negotiable part of that input.

A peptide that has degraded due to an improper formulation or an incompatible diluent may not deliver the expected results, leading to frustration and a sense of disconnect between your efforts and your body’s response. Recognizing the science within that small vial allows you to appreciate the full scope of your therapeutic protocol.

Intermediate

To truly appreciate how different formulations can protect a peptide, we must examine the environment of the lyophilized vial and the stresses of reconstitution. The freeze-drying process itself is a carefully controlled ordeal designed to shepherd a fragile molecule into a state of suspended animation.

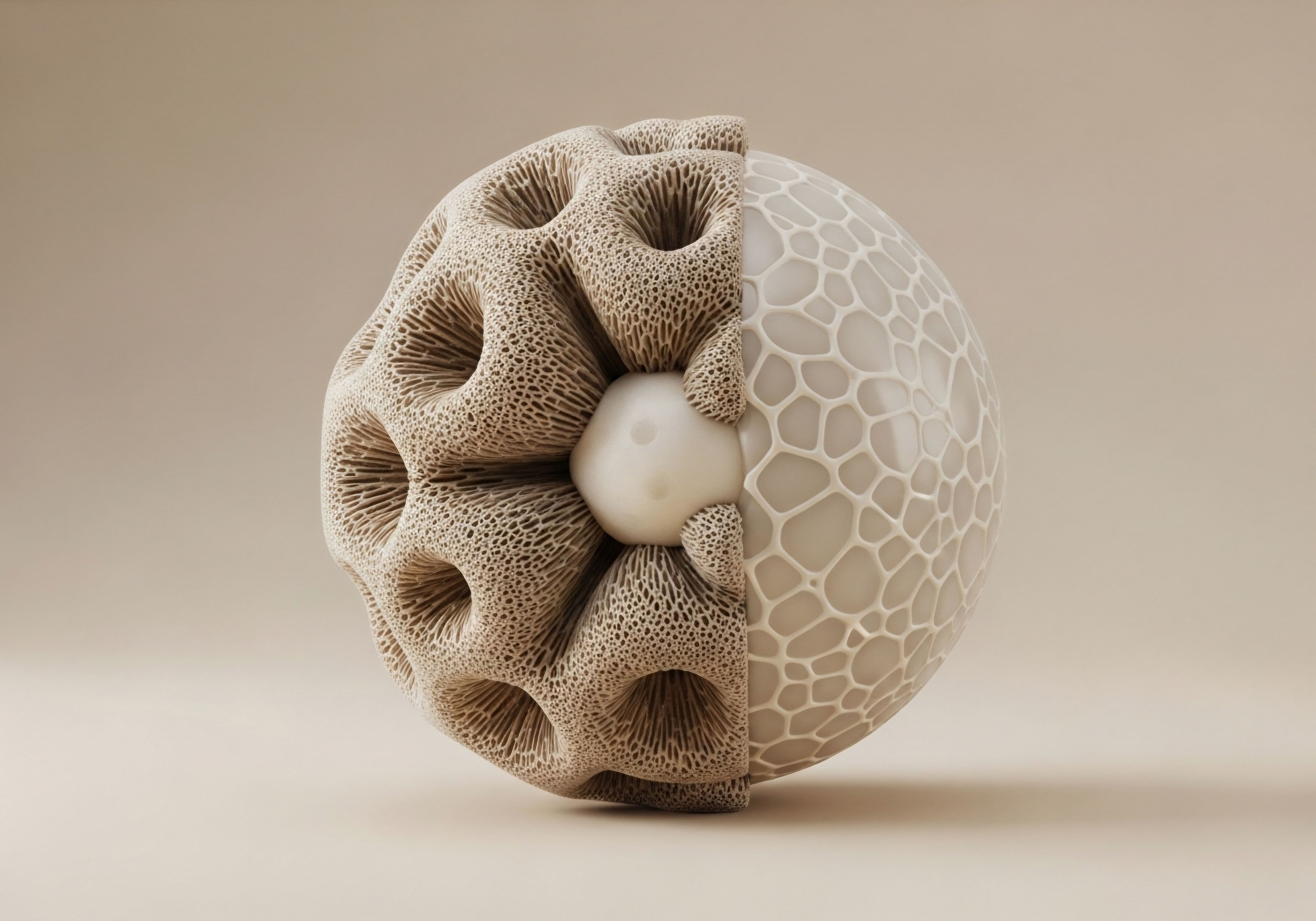

The resulting lyophilized “cake” is a porous, solid matrix containing the peptide and a thoughtfully selected blend of excipients. These excipients are the unsung heroes of peptide stability, each chosen for a specific protective role. Their collective purpose is to create a safe local environment for the peptide, both in its dry state and upon its return to a liquid form.

Peptide molecules are vulnerable to several forms of degradation. Physical instability often involves changes in the peptide’s three-dimensional structure, leading to aggregation, where molecules clump together, or adsorption, where they stick to the surface of the vial. Chemical instability involves the breaking or forming of covalent bonds, leading to oxidation, hydrolysis (breakdown by water), or deamidation. A well-designed formulation anticipates these risks and includes excipients to counteract them.

The Architectural Components of a Peptide Formulation

The selection of excipients is a highly specific process tailored to the unique biochemical properties of each peptide. These compounds are chosen to work in concert, creating a stable system. The primary categories of these architectural components are essential for the peptide’s integrity.

| Excipient Category | Primary Function | Common Examples | Mechanism of Action |

|---|---|---|---|

| Bulking Agents | Provide structure and mass to the lyophilized cake. | Mannitol, Glycine | Forms a crystalline or amorphous scaffold that prevents the vial’s contents from collapsing, ensuring an elegant appearance and rapid dissolution. |

| Lyoprotectants | Protect peptides from stress during the freeze-drying process. | Sucrose, Trehalose | Forms a glassy, amorphous matrix around the peptide, replacing the water molecules that normally hydrate it and preserving its native conformation. |

| Cryoprotectants | Protect peptides from damage during the freezing stage. | Sucrose, Polyols (e.g. Sorbitol) | Reduces the damage caused by the formation of ice crystals and the freeze-concentration of solutes. |

| Buffers | Maintain an optimal pH for the peptide’s stability. | Phosphate, Citrate, Histidine | Resists shifts in pH during processing and upon reconstitution, as pH changes can accelerate chemical degradation. |

| Tonicity Modifiers | Adjust the osmotic pressure of the reconstituted solution. | Sodium Chloride, Mannitol | Ensures the solution is isotonic with bodily fluids, reducing pain or irritation upon injection. |

The careful selection of excipients in a lyophilized formulation provides a multi-layered defense against peptide degradation.

How Can Diluent Choice Impact the Formulation?

The diluent is the activating partner to the lyophilized formulation. While often viewed as a simple solvent, its composition directly influences the stability of the newly reconstituted peptide. The choice between common diluents like sterile water and bacteriostatic water introduces significant variables that interact with the carefully balanced excipient matrix.

Sterile Water for Injection is pure H2O, free of any antimicrobial agents or other solutes. When used as a diluent, it creates a solution whose properties are dictated solely by the peptide and the excipients in the lyophilized cake. This can be advantageous for peptides that are sensitive to preservatives. The absence of a bacteriostatic agent means the reconstituted vial is intended for single use, as there is no protection against microbial contamination once the vial seal is punctured.

Bacteriostatic Water for Injection contains sterile water and 0.9% benzyl alcohol, which acts as a preservative. This allows for multiple withdrawals from the same vial over a period of time, typically up to 28 days. The presence of benzyl alcohol, however, is a critical consideration. While it prevents bacterial growth, it can also interact with the peptide.

For some peptides, benzyl alcohol can act as a mild denaturant or promote aggregation, potentially compromising the product’s integrity over time. A well-designed formulation for multi-use will have tested the peptide’s compatibility with benzyl alcohol. For peptides like BPC-157 or TB-500, this is a standard practice. For others, particularly more complex or sensitive molecules, sterile water may be specified to avoid this interaction.

The pH of the diluent, though generally neutral, can also be a factor. If a formulation relies heavily on a specific buffer system to maintain a precise pH range for stability, introducing a large volume of an unbuffered diluent can slightly alter that equilibrium. Sophisticated formulations account for this dilution effect to ensure the final pH of the reconstituted product remains within the optimal range for the peptide’s stability.

Academic

The mitigation of diluent-related stability challenges in peptide therapeutics is a function of advanced formulation science, grounded in the principles of physical chemistry and molecular biophysics. The lyophilized state is not merely the absence of water; it is a precisely engineered solid-state system designed to immobilize the peptide within a protective, amorphous matrix.

The stability of this system, and its subsequent performance upon reconstitution, depends on the thermodynamic properties of the formulation and the kinetic barriers established to prevent degradation pathways.

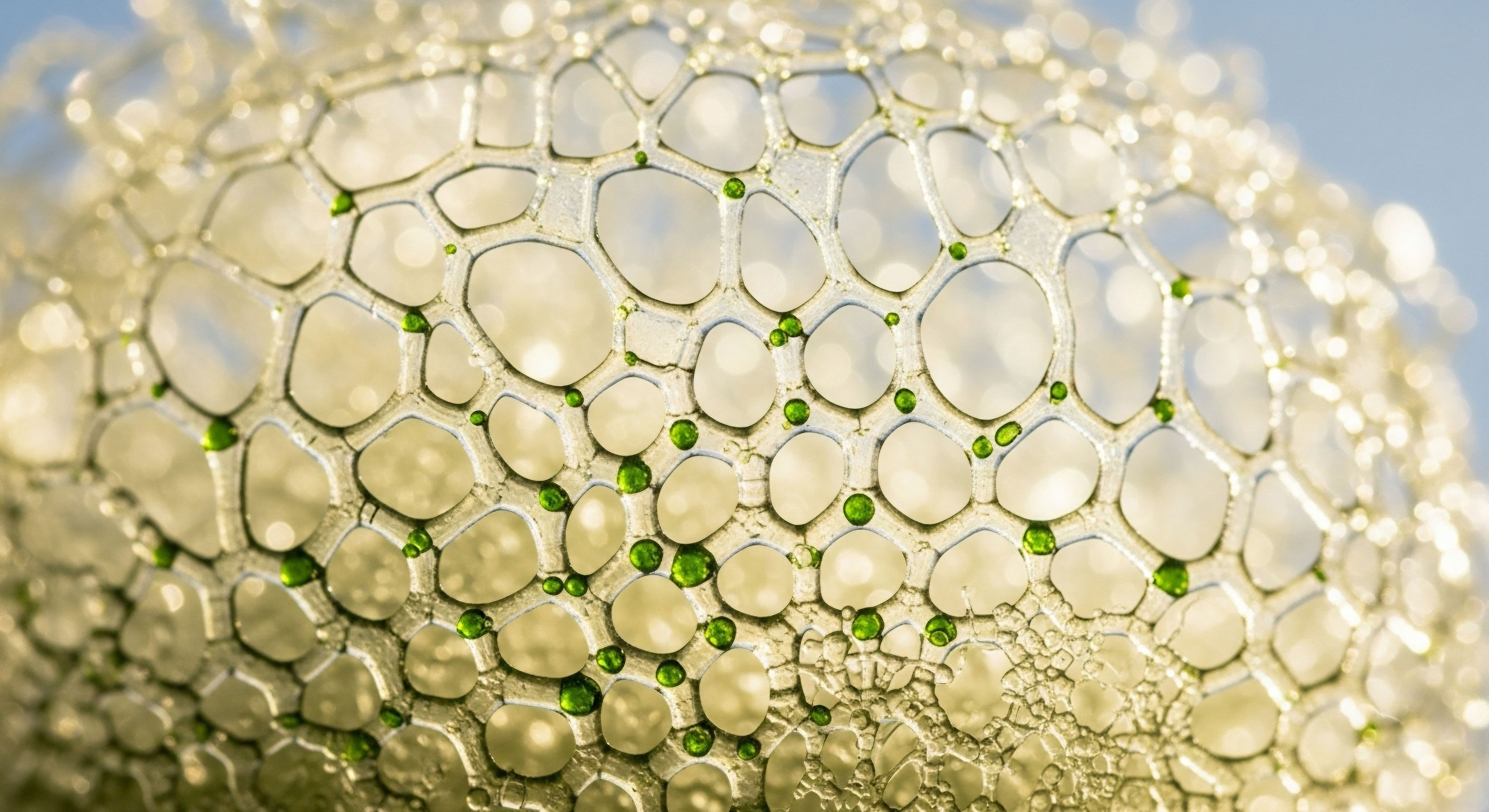

A central concept in lyophilization is the glass transition temperature (Tg). This is the temperature at which a formulation transitions from a rigid, glassy state to a more rubbery, viscous fluid. Below the Tg, molecular mobility is severely restricted, effectively halting diffusion-limited degradation reactions.

A successful formulation has a Tg that is well above its intended storage temperature. The choice of excipients, particularly disaccharides like sucrose and trehalose, is critical for achieving a high Tg. These sugars are excellent lyoprotectants because they are proficient at forming a hydrogen-bonded, amorphous glass that structurally mimics the hydration shell the peptide possesses in its native aqueous state.

This is often explained by the water replacement hypothesis, which posits that the hydroxyl groups on the sugar molecules substitute for water molecules, forming hydrogen bonds with the peptide’s polar groups and physically preventing conformational changes.

The Molecular Dance of Reconstitution

When a diluent is introduced, the stable, glassy matrix dissolves, and the peptide is re-solvated. This moment is fraught with risk. The formulation must be designed to manage this transition seamlessly. One challenge is the potential for certain excipients to crystallize during storage or upon contact with the diluent.

For example, mannitol is an excellent bulking agent, but it can exist in multiple crystalline forms, some of which may form over time. If mannitol crystallizes, it can disrupt the amorphous matrix, creating pockets of high molecular mobility where the peptide is left unprotected. Even more, the crystallization of some components can release entrapped water, raising the local water activity and accelerating hydrolytic degradation pathways.

Formulations may therefore use a combination of crystalline bulking agents and amorphous lyoprotectants. The goal is to create a structurally sound cake with a high Tg, ensuring the peptide remains locked within the protective amorphous phase.

Recent studies using solid-state nuclear magnetic resonance (ssNMR) spectroscopy have allowed researchers to probe the molecular mobility and homogeneity of lyophilized systems on a nanoscale, revealing the subtle ways that different excipients and their concentrations affect the stability of the final product. Research has shown that sucrose can sometimes create a more stable system with lower molecular mobility compared to trehalose for certain proteins.

The ultimate success of a peptide formulation lies in its ability to control molecular mobility, both in the solid state and during the transition to a liquid.

What Are the Regulatory Implications for Novel Formulations?

The development of a new peptide formulation, especially one designed to improve stability with specific diluents, is a significant undertaking with regulatory considerations. Any change to a formulation, including the type or concentration of an excipient, requires extensive stability testing to demonstrate that the product remains safe and effective throughout its shelf life. This involves storing the product under various temperature and humidity conditions and performing analytical tests at set intervals to detect any physical or chemical degradation.

The table below outlines some of the key analytical methods used to assess the stability of peptide formulations, which would be part of a regulatory submission to agencies like the FDA.

| Analytical Technique | Parameter Measured | Purpose in Stability Testing |

|---|---|---|

| High-Performance Liquid Chromatography (HPLC) | Purity and Concentration | Quantifies the amount of active peptide and detects the presence of degradation products or impurities. Reverse-phase HPLC is the standard. |

| Mass Spectrometry (MS) | Molecular Weight and Sequence | Identifies the peptide and characterizes chemical modifications such as oxidation or deamidation by confirming its precise mass. |

| Circular Dichroism (CD) Spectroscopy | Secondary and Tertiary Structure | Assesses the peptide’s conformational integrity. Changes in the CD spectrum can indicate unfolding or aggregation. |

| Size Exclusion Chromatography (SEC) | Aggregates and Fragments | Separates molecules based on size to quantify the presence of high-molecular-weight aggregates or low-molecular-weight fragments. |

| Karl Fischer Titration | Residual Moisture Content | Measures the amount of water remaining in the lyophilized cake, a critical parameter as excess moisture can severely compromise stability. |

For therapeutic peptides used in hormonal optimization protocols, such as Sermorelin or CJC-1295/Ipamorelin, ensuring stability is paramount. These peptides work by stimulating the pituitary gland, and their precise structure is essential for binding to the Growth Hormone-Releasing Hormone receptor.

A degraded or aggregated peptide will have reduced or no biological activity, failing to produce the desired downstream release of growth hormone. Therefore, the formulation science that protects these molecules is directly linked to the clinical outcome of the protocol.

Advanced formulations might incorporate novel excipients, such as specific amino acids like histidine or arginine, which can act as both buffers and stabilizers, or cyclodextrins, which can encapsulate and protect certain parts of a peptide molecule. Each new approach must be rigorously validated to ensure it effectively mitigates the stability challenges posed by both storage and the inevitable interaction with a diluent.

References

- Joshi, Sachin, et al. “Mini Review on the Lyophilization ∞ A Basic Requirement for Formulation Development and Stability Modifier.” ASSAY and Drug Development Technologies, Feb. 2025.

- Fransson, J. and L. Sjöblom. “Recent trends in stabilising peptides and proteins in pharmaceutical formulation – Considerations in the choice of excipients.” European Journal of Pharmaceutical Sciences, vol. 7, 1999, pp. 1-13.

- Ni, John, et al. “Practical advice in the development of a lyophilized protein drug product.” Pharmaceutical Development and Technology, vol. 26, no. 6, 2021, pp. 623-635.

- Sahasrabudhe, Atharva. “IMPACT OF EXCIPIENTS ON MOBILITY AND STABILITY OF LYOPHILIZED BIOLOGICS FORMULATIONS.” Purdue University Graduate School Research Repository, 12 June 2024.

- Bocan, T. “Peptide Drug Aseptic Filling and Freeze-drying Process Development.” Creative Peptides, 2023.

- Pikal, M. J. “Freeze-drying of proteins. Part II ∞ formulation selection.” BioPharm, vol. 3, 1990, pp. 26-30.

- Wang, W. “Lyophilization and development of solid protein pharmaceuticals.” International Journal of Pharmaceutics, vol. 203, no. 1-2, 2000, pp. 1-60.

- Chang, L. and M. J. Pikal. “Mechanisms of protein stabilization in the solid state.” Journal of Pharmaceutical Sciences, vol. 98, no. 9, 2009, pp. 2886-2908.

- Carpenter, J. F. et al. “Rational design of stable lyophilized protein formulations ∞ some practical advice.” Pharmaceutical Research, vol. 14, no. 8, 1997, pp. 969-975.

Reflection

Connecting the Science to Your System

The information presented here, from the foundational role of excipients to the molecular physics of the glassy state, all converges on a single point of action ∞ the moment you reconstitute a peptide for your personal use. The science within that vial is a direct extension of the commitment you have made to your own health.

It represents a deep understanding of biology and chemistry, all focused on delivering a precise molecular message to your body. As you continue on your path, consider that each element of your protocol, no matter how small it seems, is a piece of a larger system.

Your body is a system, your therapeutic protocol is a system, and the formulation of a peptide is a system. The knowledge of how they connect allows you to move forward not just with instructions, but with intention and a deeper appreciation for the process of reclaiming your biological vitality.