Fundamentals

The question of whether a medication tailored specifically for you can match the reliability of a mass-produced pharmaceutical is a deeply personal one. It touches upon your trust in the therapeutic protocol designed to restore your vitality.

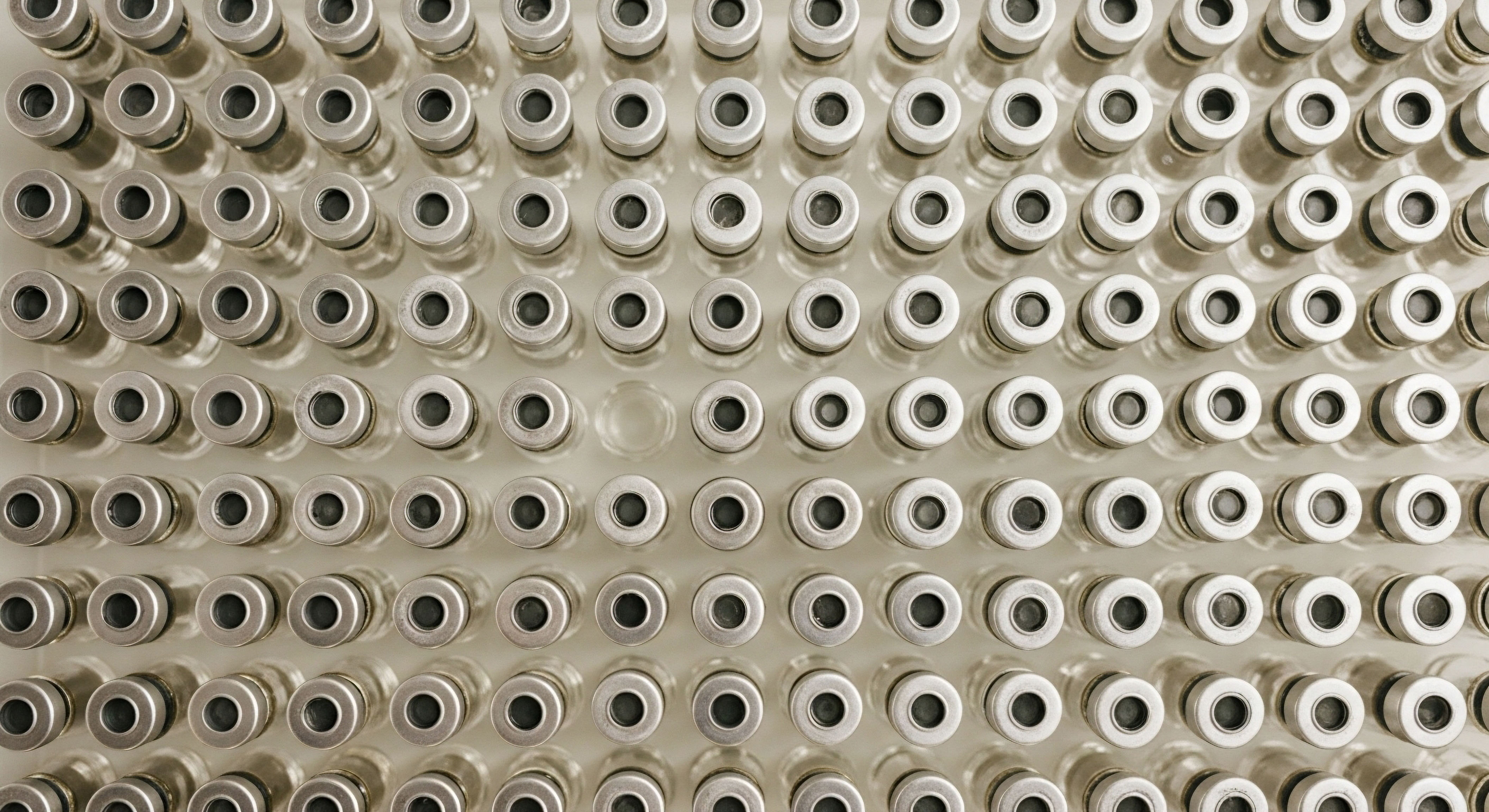

When you hold a vial of compounded Testosterone Cypionate or a peptide like Ipamorelin, you are holding a key to recalibrating your body’s intricate systems. The assurance you seek is that this key is well-made, precise, and will work as intended from the first dose to the last. This assurance is rooted in the concept of stability, which in the world of pharmacology, means the medication maintains its specific identity, strength, and purity throughout its use.

A pharmaceutical product’s journey begins with its Active Pharmaceutical Ingredient, or API. This is the core component, the molecule that interacts with your biology to produce a therapeutic effect. For a commercially manufactured drug, this API is combined with a standardized set of inactive ingredients, known as excipients, and produced in enormous batches. Each batch undergoes rigorous testing to establish a long shelf life, often spanning years. The process is built for uniformity and scale.

Compounded medications originate from a different philosophy. They are created to meet the unique needs of an individual. A physician may determine you require a specific dose of testosterone unavailable in a commercial product, or perhaps you have an allergy to a preservative or carrier oil used in a mass-marketed formulation.

This is where a compounding pharmacy steps in. A licensed pharmacist, working with pure-grade APIs and a selection of excipients, formulates a medication based on your specific prescription. This allows for personalized dosing, the combination of compatible therapies, and the use of alternative bases or carrier oils to suit your individual physiology.

The Core of Drug Stability

The stability of any medication, whether compounded or mass-produced, is its ability to remain unchanged over time. This is influenced by several environmental factors. Temperature is a primary determinant; storing a medication like Testosterone Cypionate outside its recommended range of 20°C to 25°C (68°F to 77°F) can accelerate the breakdown of the API, reducing its potency.

Exposure to light can also degrade sensitive molecules, which is why many hormonal preparations are dispensed in light-resistant vials. The chemical environment, including the carrier oil in an injectable or the base in a cream, also plays a significant role in protecting the API from degradation.

The stability of a medication is its capacity to retain its chemical integrity and therapeutic potency throughout its intended shelf life.

Both large-scale manufacturers and compounding pharmacies operate within established regulatory frameworks designed to ensure product safety and quality. Pharmaceutical companies follow the Food and Drug Administration’s (FDA) Current Good Manufacturing Practices (CGMP). Compounding pharmacies adhere to standards set by the United States Pharmacopeia (USP) and are regulated by state boards of pharmacy.

These guidelines provide the essential blueprint for everything from personnel training and ingredient sourcing to the conditions of the compounding environment itself. The goal is identical in both worlds ∞ to deliver a final product that is safe, effective, and stable for its intended duration of use.

Intermediate

Understanding the stability of compounded medications requires moving beyond the pharmacy counter and into the cleanroom where these personalized therapies are made. The reliability of a compounded sterile injectable, such as Testosterone Cypionate or a growth hormone peptide like Sermorelin, is a direct result of the procedural and environmental controls under which it is prepared. These controls are codified in a set of standards that function as the blueprint for quality and consistency in compounding.

The Regulatory Blueprint for Consistency

The United States Pharmacopeia (USP) creates the authoritative standards for pharmaceutical compounding. These chapters are the rulebook that ensures a compounded medication is what it purports to be. For the therapies central to hormonal and metabolic health, two chapters are of primary importance.

- USP General Chapter <795> provides the standards for nonsterile compounding. This applies to preparations like topical hormone creams, oral capsules, or sublingual troches. The chapter outlines requirements for ingredient sourcing, process controls, and establishing Beyond-Use Dates (BUDs) to ensure the preparation remains potent and safe for the patient.

- USP General Chapter <797> sets the standards for sterile compounding. This is the critical framework for all injectable therapies, including Testosterone Replacement Therapy (TRT) and peptide protocols. It mandates stringent environmental controls, including the use of cleanrooms and laminar flow hoods, to prevent microbial contamination. It also specifies rigorous protocols for personnel training, sterile technique validation, and environmental monitoring.

These USP chapters provide the foundational science for creating stable formulations. Adherence to these standards is the primary mechanism through which a compounding pharmacy ensures the quality of its preparations, from a single prescription to a batch prepared for a clinic.

How Are Compounding Pharmacies Regulated?

The regulatory landscape for compounding pharmacies is divided into two distinct categories, a division that has significant implications for the scale and oversight of their operations. This distinction is defined by sections 503A and 503B of the Federal Food, Drug, and Cosmetic Act.

| Feature | 503A Compounding Pharmacy | 503B Outsourcing Facility |

|---|---|---|

| Primary Function | Compounds medications based on patient-specific prescriptions. | Produces large batches of compounded drugs with or without prescriptions for office use. |

| Regulatory Oversight | Primarily regulated by State Boards of Pharmacy and must comply with USP <795> and <797>. | Operates under FDA oversight and must adhere to Current Good Manufacturing Practices (CGMP). |

| Prescription Requirement | A unique prescription is required for each compounded preparation. | Can produce “office stock” for healthcare facilities without patient-specific prescriptions. |

| Scale of Production | Typically smaller scale, focused on individual patient needs. | Large-scale production, functioning similarly to a traditional pharmaceutical manufacturer. |

A 503B outsourcing facility, by virtue of its need to comply with CGMP, operates under a quality control system that mirrors that of a large pharmaceutical manufacturer. This includes process validation, stability testing for every batch, and stringent supplier verification.

For a physician prescribing a common protocol like weekly Testosterone Cypionate injections to many patients, sourcing from a 503B facility can provide an additional layer of documented consistency. A 503A pharmacy provides essential access to personalized therapies for unique patient needs, operating with robust quality controls mandated by USP standards.

Formulation the Science of the Vehicle

The stability of an active ingredient is profoundly influenced by the excipients it is combined with. In the context of injectable testosterone, the carrier oil is the most important excipient. Historically, grapeseed oil was a common choice. However, the pharmaceutical quality of grapeseed oil can be inconsistent, and it is susceptible to oxidation.

To enhance stability, many forward-thinking compounding pharmacies now utilize alternative carrier oils like Miglyol, a highly purified medium-chain triglyceride oil. Miglyol demonstrates high stability against oxidation, ensuring the testosterone molecule remains intact and potent for longer. The choice of excipient is a deliberate scientific decision made to maximize the stability and safety of the final preparation.

The selection of specific excipients, such as advanced carrier oils, is a critical factor in protecting the active pharmaceutical ingredient from degradation.

Academic

An academic evaluation of stability compares the molecular integrity of compounded preparations to their mass-produced counterparts by examining the specific chemical degradation pathways of the active pharmaceutical ingredients. The central question becomes one of chemical kinetics and formulation science. While regulatory frameworks like USP standards and CGMP provide the necessary conditions for quality, the inherent chemical nature of the drug molecule itself dictates the specific challenges to maintaining its stability.

Molecular Integrity of Hormonal Therapies

For small-molecule drugs like Testosterone Cypionate, stability is largely a function of protecting the molecule from hydrolysis and oxidation. The testosterone molecule is esterified with cypionic acid to form Testosterone Cypionate. This ester linkage slows the release of the hormone into the bloodstream after intramuscular injection.

The primary degradation pathway involves the hydrolysis of this ester bond, which would sever the cypionate tail from the testosterone molecule, altering its pharmacokinetics. This reaction is accelerated by deviations from optimal pH and exposure to heat.

Therefore, the stability of compounded testosterone hinges on using a pure, stable API, formulating it in a pH-neutral and non-reactive carrier oil, and maintaining proper storage conditions away from heat and light. High-quality compounding pharmacies, particularly 503B facilities, will perform stability-indicating assays using techniques like High-Performance Liquid Chromatography (HPLC) to confirm the concentration and purity of their testosterone preparations over time.

What Is the Chemical Stability of Peptides?

Peptide therapeutics, such as Ipamorelin, CJC-1295, and Sermorelin, present a more complex stability challenge. As chains of amino acids, they possess a more fragile and intricate three-dimensional structure that is essential for their biological activity. Their stability is threatened by several distinct chemical degradation pathways.

The inherent chemical fragility of peptide chains necessitates exacting formulation and handling protocols to preserve their biological function.

These molecules are susceptible to degradation mechanisms that are less of a concern for simpler small-molecule drugs. Understanding these pathways is fundamental to appreciating the science behind compounding and handling these advanced therapies.

| Degradation Pathway | Description | Susceptible Residues | Consequence |

|---|---|---|---|

| Oxidation | The addition of oxygen atoms, often initiated by exposure to atmospheric oxygen or trace metals. This reaction alters the side chain of the amino acid. | Methionine (Met), Cysteine (Cys), Tryptophan (Trp), Histidine (His). | Loss of biological activity due to conformational changes in the peptide structure. |

| Deamidation | The removal of an amide group from a side chain, which converts the amino acid into a different one and introduces a negative charge. This is highly pH-dependent. | Asparagine (Asn), Glutamine (Gln). | Can significantly alter the peptide’s structure and its ability to bind to its target receptor, rendering it inactive. |

| Hydrolysis | The cleavage of the peptide bond between amino acids, catalyzed by water. This process is accelerated at pH extremes. | Aspartic Acid (Asp), especially when next to Proline (Pro) or Glycine (Gly). | Results in fragmentation of the peptide chain, leading to complete loss of function. |

| Racemization | The conversion of a naturally occurring L-amino acid into its non-functional D-amino acid mirror image. | Aspartic Acid (Asp), Serine (Ser). | The resulting peptide may be inactive or have an altered, unpredictable biological effect. |

Beyond-Use Dating a Data-Driven Approach

The concept of a Beyond-Use Date (BUD) is where the practical differences between mass-produced and compounded medications are most apparent. A pharmaceutical manufacturer invests immense resources into multi-year, real-time stability studies for a specific formulation in its final commercial packaging. This allows them to establish a long shelf life.

For compounded medications, the BUD is determined according to guidelines in USP chapters. This date is set based on the type of formulation, whether it contains water, and the storage temperature. For a sterile injectable peptide reconstituted in bacteriostatic water, the BUD is typically much shorter, often 28 days, because the aqueous environment makes degradation pathways like hydrolysis and deamidation more likely.

A high-quality compounding pharmacy may conduct its own stability studies for its specific formulations to justify extending a BUD, but this requires rigorous analytical testing. The shorter BUD on a compounded medication is a reflection of a scientifically conservative approach designed to ensure the patient receives the medication at its full potency and purity.

References

- U.S. Pharmacopeia. General Chapter <795> Pharmaceutical Compounding ∞ Nonsterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ U.S. Pharmacopeial Convention; 2020.

- U.S. Pharmacopeia. General Chapter <797> Pharmaceutical Compounding ∞ Sterile Preparations. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ U.S. Pharmacopeial Convention; 2020.

- U.S. Pharmacopeia. General Chapter <800> Hazardous Drugs ∞ Handling in Healthcare Settings. In ∞ United States Pharmacopeia and National Formulary (USP 43-NF 38). Rockville, MD ∞ U.S. Pharmacopeial Convention; 2020.

- Manning, M. C. Chou, D. K. Murphy, B. M. Payne, R. W. & Katayama, D. S. (2010). Stability of protein pharmaceuticals ∞ an update. Pharmaceutical research, 27(4), 544 ∞ 575.

- Powell, Michael F. and T. J. L. Nguyen. “Chemical pathways of peptide degradation. II. Kinetics of deamidation of an asparaginyl residue in a model hexapeptide.” Pharmaceutical research 7.11 (1990) ∞ 1141-1154.

- FDA.gov. “Compounding and the FDA ∞ Questions and Answers.” U.S. Food and Drug Administration, 2023.

- Glass, B. D. & Haywood, A. (2006). Stability considerations in liquid dosage forms extemporaneously prepared from commercially available products. Journal of Pharmacy & Pharmaceutical Sciences, 9(3), 398-426.

- Kastango, E. S. & Bradshaw, B. D. (2014). USP chapter <797> ∞ The new testament for sterile compounding. International Journal of Pharmaceutical Compounding, 18(1), 23-28.

Reflection

You began this exploration seeking certainty about the medications that form the foundation of your personalized health protocol. The journey through the science of stability reveals that the reliability of any therapeutic agent, whether from a global manufacturer or a dedicated compounding pharmacist, is born from precision, control, and an understanding of its fundamental chemistry. The stability of your compounded medication is an active partnership between the formulating pharmacist who builds it and you, the patient who protects it.

This knowledge transforms you from a passive recipient into an informed participant in your own care. It empowers you to ask meaningful questions ∞ Is this formulation optimized for stability? What are the specific storage requirements I must follow to protect its integrity?

Understanding the science behind your therapy is the first, most definitive step toward reclaiming your biological vitality. The path forward is one of collaboration with your clinical team, armed with the clarity that your personalized protocol is built upon a foundation of scientific rigor.

Glossary

testosterone cypionate

compounded medications

carrier oil

compounding pharmacy

current good manufacturing practices

united states pharmacopeia

pharmaceutical compounding

sterile compounding

compounding pharmacies

cgmp

503b facility

excipient

oxidation

degradation pathways

formulation science

peptide therapeutics